6월 . 15, 2024 22:40 Back to list

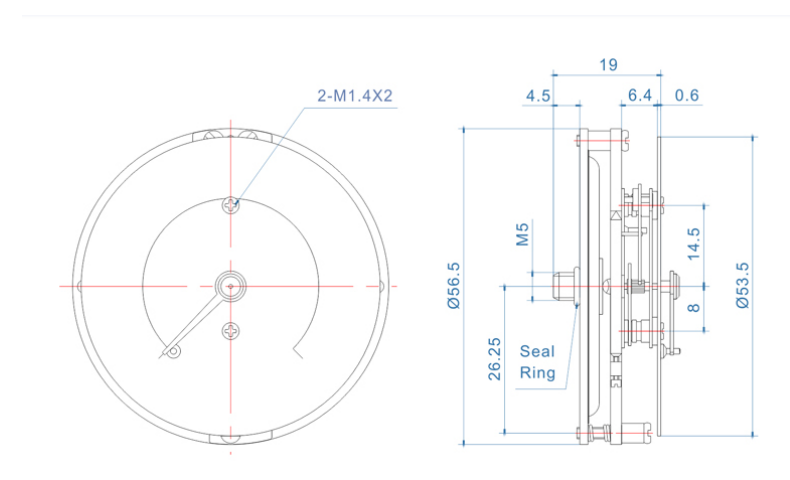

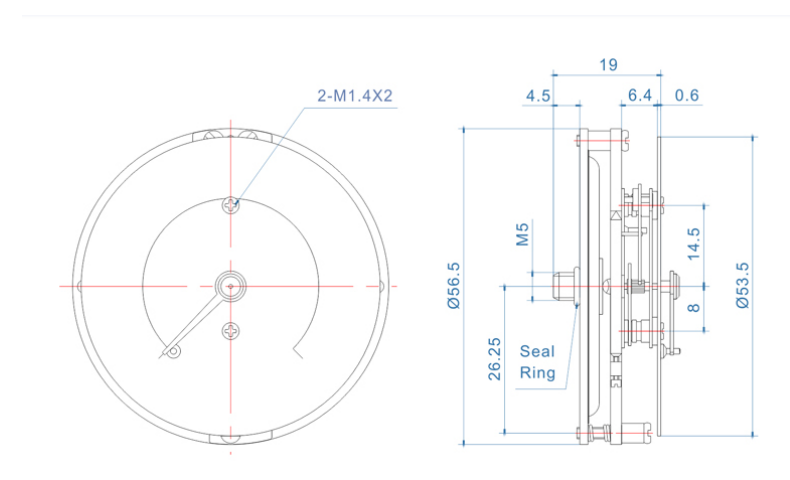

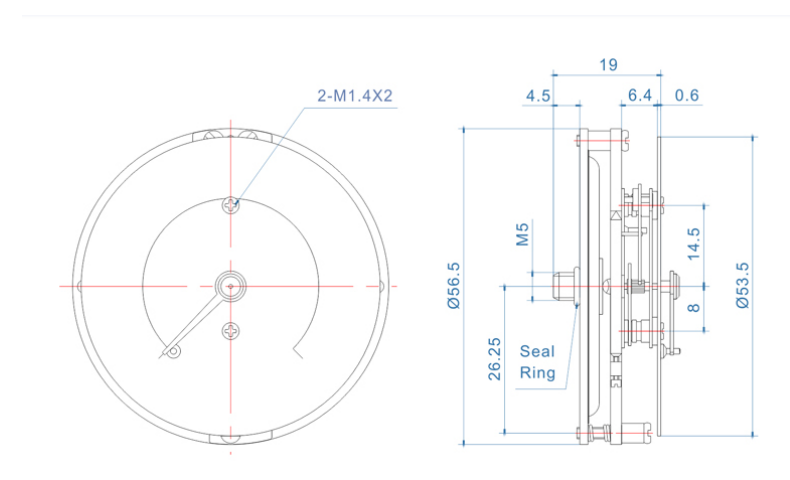

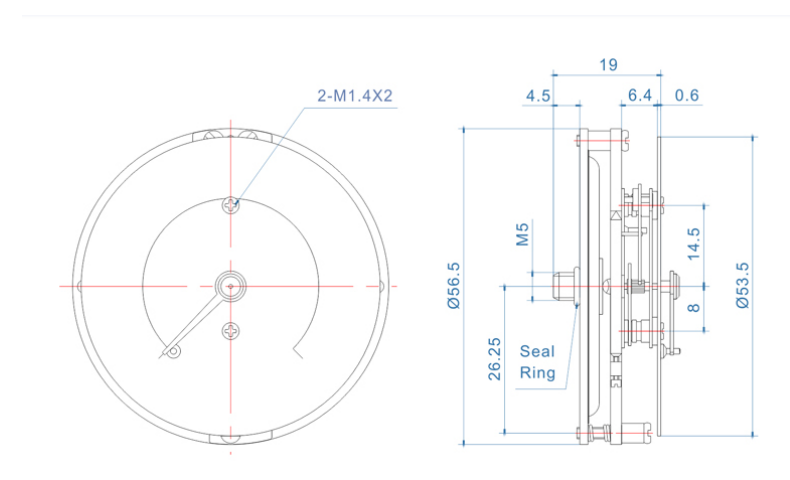

Sealed capillary differential pressure gauge for precise measurement.

Understanding the Functionality of a Differential Pressure Gauge with Sealed Capillary A Comprehensive Overview

In the realm of industrial instrumentation and control systems, a differential pressure gauge with a sealed capillary stands as an essential tool for measuring pressure differentials in various applications. This specialized device is designed to provide accurate and reliable readings, especially in environments where standard pressure gauges may falter due to harsh conditions or remote locations.

A differential pressure gauge measures the difference between two pressures at separate points in a system. It operates by comparing the pressure acting on two diaphragms or Bourdon tubes, which are connected to the process through tappings. The result is a direct indication of the pressure difference, displayed on the gauge's dial.

The sealed capillary, an integral part of this system, serves as a protective extension between the gauge and the measurement point. It is typically filled with a non-corrosive fluid, such as glycerin or silicone oil, which transfers the pressure from the process to the gauge while isolating it from the surrounding environment. This sealing mechanism ensures that the gauge remains protected from contaminants, extreme temperatures, and pressure fluctuations that could otherwise compromise its accuracy.

One key advantage of a differential pressure gauge with a sealed capillary is its ability to measure pressure over long distances. The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel

The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel differential pressure gauge with sealed capilary jah. Additionally, the sealed design enhances the gauge's durability, making it suitable for use in corrosive, explosive, or high-temperature environments.

Moreover, these gauges find extensive use in industries like oil and gas, water treatment, chemical processing, and HVAC systems, where precise measurement of pressure differentials is crucial for optimal performance and safety. They are also employed in filter monitoring, level measurement, and flow rate calculations, among other applications.

Maintenance and calibration of a differential pressure gauge with a sealed capillary require attention to ensure continued accuracy. Regular inspections should be conducted to check for leaks or damage to the capillary, while periodic calibration is necessary to maintain the gauge's precision.

In conclusion, a differential pressure gauge with a sealed capillary is a robust and reliable instrument that plays a vital role in numerous industrial processes. Its unique design, combining accurate pressure measurement with protection against environmental factors, makes it a go-to solution for engineers and technicians seeking dependable performance in challenging conditions. By understanding its operation and maintenance requirements, users can harness its full potential to enhance efficiency and safety in their respective applications.

differential pressure gauge with sealed capilary jah. Additionally, the sealed design enhances the gauge's durability, making it suitable for use in corrosive, explosive, or high-temperature environments.

Moreover, these gauges find extensive use in industries like oil and gas, water treatment, chemical processing, and HVAC systems, where precise measurement of pressure differentials is crucial for optimal performance and safety. They are also employed in filter monitoring, level measurement, and flow rate calculations, among other applications.

Maintenance and calibration of a differential pressure gauge with a sealed capillary require attention to ensure continued accuracy. Regular inspections should be conducted to check for leaks or damage to the capillary, while periodic calibration is necessary to maintain the gauge's precision.

In conclusion, a differential pressure gauge with a sealed capillary is a robust and reliable instrument that plays a vital role in numerous industrial processes. Its unique design, combining accurate pressure measurement with protection against environmental factors, makes it a go-to solution for engineers and technicians seeking dependable performance in challenging conditions. By understanding its operation and maintenance requirements, users can harness its full potential to enhance efficiency and safety in their respective applications.

The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel

The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel The capillary's length can be customized to accommodate remote installations, allowing monitoring in areas that are difficult to access or hazardous to personnel differential pressure gauge with sealed capilary jah. Additionally, the sealed design enhances the gauge's durability, making it suitable for use in corrosive, explosive, or high-temperature environments.

Moreover, these gauges find extensive use in industries like oil and gas, water treatment, chemical processing, and HVAC systems, where precise measurement of pressure differentials is crucial for optimal performance and safety. They are also employed in filter monitoring, level measurement, and flow rate calculations, among other applications.

Maintenance and calibration of a differential pressure gauge with a sealed capillary require attention to ensure continued accuracy. Regular inspections should be conducted to check for leaks or damage to the capillary, while periodic calibration is necessary to maintain the gauge's precision.

In conclusion, a differential pressure gauge with a sealed capillary is a robust and reliable instrument that plays a vital role in numerous industrial processes. Its unique design, combining accurate pressure measurement with protection against environmental factors, makes it a go-to solution for engineers and technicians seeking dependable performance in challenging conditions. By understanding its operation and maintenance requirements, users can harness its full potential to enhance efficiency and safety in their respective applications.

differential pressure gauge with sealed capilary jah. Additionally, the sealed design enhances the gauge's durability, making it suitable for use in corrosive, explosive, or high-temperature environments.

Moreover, these gauges find extensive use in industries like oil and gas, water treatment, chemical processing, and HVAC systems, where precise measurement of pressure differentials is crucial for optimal performance and safety. They are also employed in filter monitoring, level measurement, and flow rate calculations, among other applications.

Maintenance and calibration of a differential pressure gauge with a sealed capillary require attention to ensure continued accuracy. Regular inspections should be conducted to check for leaks or damage to the capillary, while periodic calibration is necessary to maintain the gauge's precision.

In conclusion, a differential pressure gauge with a sealed capillary is a robust and reliable instrument that plays a vital role in numerous industrial processes. Its unique design, combining accurate pressure measurement with protection against environmental factors, makes it a go-to solution for engineers and technicians seeking dependable performance in challenging conditions. By understanding its operation and maintenance requirements, users can harness its full potential to enhance efficiency and safety in their respective applications. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025