Sep . 28, 2024 23:18 Back to list

Analogue Differential Pressure Gauges for Accurate Measurement Solutions in Industrial Applications

Understanding Analogue Differential Pressure Gauges An Overview of Their Importance and Applications

Analogue differential pressure gauges are essential instruments used across various industries to measure the difference in pressure between two points within a system. These devices play a crucial role in ensuring the efficiency, safety, and performance of processes involving gases and liquids. The significance of differential pressure measurement cannot be overstated, as it helps monitor filters, pumps, compressors, and other equipment, ensuring they function optimally.

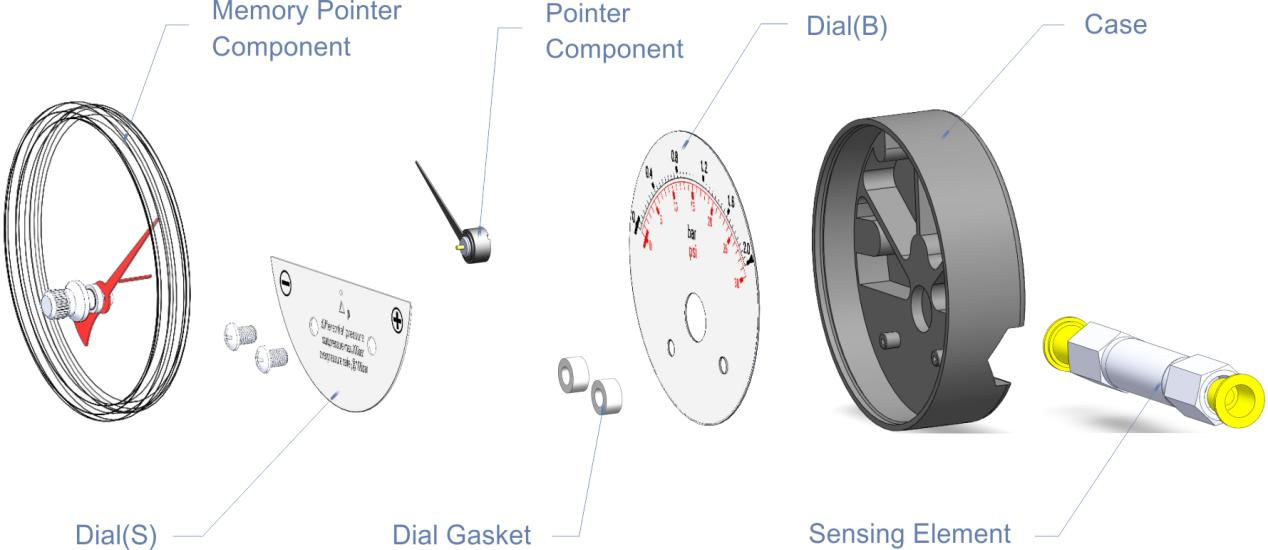

Differential pressure gauges operate based on the principle of measuring the pressure difference between two points. Typically, they consist of a sensing element, such as a diaphragm or a bourdon tube, which deforms under pressure changes. This deformation is then translated into a readable measurement displayed on an analogue dial. The simplicity of analogue gauges is one of their key advantages, making them user-friendly and easy to interpret at a glance.

One of the primary applications of analogue differential pressure gauges is in monitoring the performance of filtration systems. In industries such as pharmaceuticals, food and beverage, and water treatment, maintaining pressure integrity is vital. As filters become clogged with particles or contaminants, the differential pressure increases, prompting operators to replace or clean the filters. By regularly monitoring this pressure differential, businesses can prevent system failures and maintain optimal performance, ultimately saving costs and ensuring product quality.

Another critical application is in HVAC (Heating, Ventilation, and Air Conditioning) systems. In this domain, differential pressure gauges are used to measure the pressure drop across air filters, ducts, and other components. Accurate readings enable facility managers to determine when to replace filters and assess the efficiency of the entire HVAC system. This preventive maintenance helps in energy conservation, reducing operational costs while enhancing indoor air quality.

analogue differential pressure gauge company

In the petrochemical industry, analogue differential pressure gauges are vital for monitoring pressure in pipelines, reactors, and separation units. A sudden change in pressure can indicate leaks or blockages that may lead to catastrophic events if not addressed promptly. By employing these gauges, companies can quickly identify issues and take corrective actions to mitigate risks.

Moreover, analogue differential pressure gauges are also widely used in laboratory environments. In such settings, precise measurements are critical for experiments and analyses. These gauges provide researchers with real-time data on pressure fluctuations, allowing them to make informed decisions and adjustments as necessary.

Despite the rise of digital technology in pressure measurement, analogue differential pressure gauges continue to hold their ground due to their reliability, robust design, and cost-effectiveness. They do not require batteries or complex electronics, making them ideal for harsh environments where electronic devices may fail. Furthermore, the absence of digital displays minimizes susceptibility to damage from moisture, dust, and extreme temperatures.

When selecting an analogue differential pressure gauge, several factors must be considered, including the pressure range, accuracy, and the type of fluids being measured. It's also essential to ensure that the gauge complies with industry standards and regulations to guarantee safety and performance.

In conclusion, analogue differential pressure gauges remain an integral part of many industrial processes. Their ability to provide accurate, real-time pressure measurements ensures that systems operate smoothly and efficiently. As industries continue to evolve, the significance of reliable pressure measurement tools like analogue differential pressure gauges will only increase, highlighting their enduring value across various applications. Whether in manufacturing, HVAC, or laboratory testing, these gauges play a vital role in maintaining safety, efficiency, and optimal performance in countless operations worldwide.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025