Dec . 20, 2024 15:19 Back to list

Differential Pressure Gauge Diaphragm Pricing and Specifications Overview

Understanding Differential Pressure Gauge Diaphragm A Pricing Perspective

In the world of industrial measurement, differential pressure gauges play a pivotal role in ensuring the proper functioning of various systems. These instruments, particularly those utilizing diaphragm technology, are designed to measure the difference in pressure between two points. They are essential in applications ranging from HVAC systems to chemical processing, helping operators maintain optimal conditions and prevent equipment failures. Understanding the pricing landscape of differential pressure gauge diaphragms is crucial for procurement professionals and engineers alike.

What are Differential Pressure Gauges?

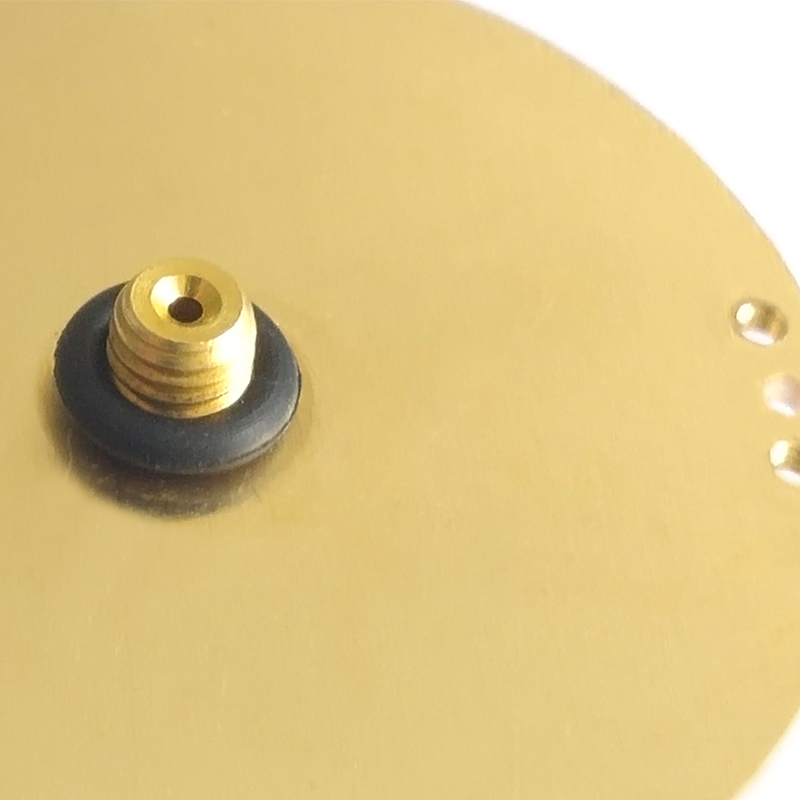

Differential pressure gauges measure the pressure difference between two points in a system. They typically consist of two pressure ports connected to a diaphragm. When one side experiences higher pressure than the other, the diaphragm flexes, creating a mechanical motion that can be translated into a pressure reading. This technology is favored for its reliability and accuracy, particularly in environments where conditions can vary significantly.

Factors Affecting Pricing

1. Material and Construction The material used in constructing the diaphragm can significantly impact the price. Common materials include stainless steel, which is durable and corrosion-resistant, and various elastomers for different applications. Special materials can be required for extreme conditions, which can drive up costs. 2. Pressure Range and Accuracy Gauges are available across various pressure ranges and with differing levels of accuracy. Higher precision gauges typically come with a higher price tag. Moreover, the ability to withstand high pressure or vacuum conditions can influence the pricing significantly.

3. Technology Type Different technologies, such as analog vs. digital gauges, can have different price points. Digital gauges often incorporate advanced features like data logging capabilities, which can enhance operational efficiency but also come at a higher cost.

4. Manufacturer Reputation Established manufacturers who are known for quality and reliability often have higher prices. This is because their products are trusted in critical applications and come with warranties and dedicated customer support.

5. Customization and Additional Features Custom-built gauges or those with specific features, such as alarms, remote monitoring, or enhanced environmental protection ratings, will typically be priced higher than standard options.

differential pressure gauge diaphragm pricelist

A Glimpse at Pricing Trends

The pricing for differential pressure gauge diaphragms can vary widely, typically ranging from $150 to over $1,000. For example, a standard diaphragm gauge with a basic configuration might cost around $200, whereas a high-end model equipped with advanced features could cost upwards of $800.

Bulk purchasing and long-term contracts can also provide significant savings. Distributors and manufacturers often offer discounts for larger orders, helping companies manage their operational budgets effectively.

The Importance of Research and Selection

When considering the procurement of differential pressure gauge diaphragms, it is essential to conduct thorough research. Comparing prices across different manufacturers, examining specifications, and understanding warranty policies are all crucial steps in making an informed decision.

Moreover, it is advisable to consult with technical experts to ensure that the selected gauge meets the application’s specific requirements. Missteps in this area can lead to inaccurate measurements and subsequent operational issues, potentially resulting in costly downtime.

Conclusion

In summary, the differential pressure gauge diaphragm market presents a wide range of options in terms of pricing and features. By understanding the factors that influence pricing and conducting comprehensive research, companies can make informed decisions that align with their operational needs and budget constraints. As technology continues to evolve, staying abreast of industry trends and advancements will also be key to making the most effective purchasing choices in this critical area of industrial measurement.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025