Jul . 25, 2024 08:23 Back to list

Exporter of High-Quality Sanitary Diaphragm Pressure Gauges for Precision Measurement Applications.

The Importance of Wika Sanitary Diaphragm Pressure Gauges in Industrial Applications

In various industrial sectors, the reliability and accuracy of pressure measurement are paramount to ensure the safety and efficiency of processes. One prominent solution in this field is the Wika sanitary diaphragm pressure gauge, which is specifically designed for the food and beverage, pharmaceutical, and biotechnology industries. This article explores the features, advantages, and applications of Wika sanitary diaphragm pressure gauges, highlighting their importance in modern industrial operations.

Features of Wika Sanitary Diaphragm Pressure Gauges

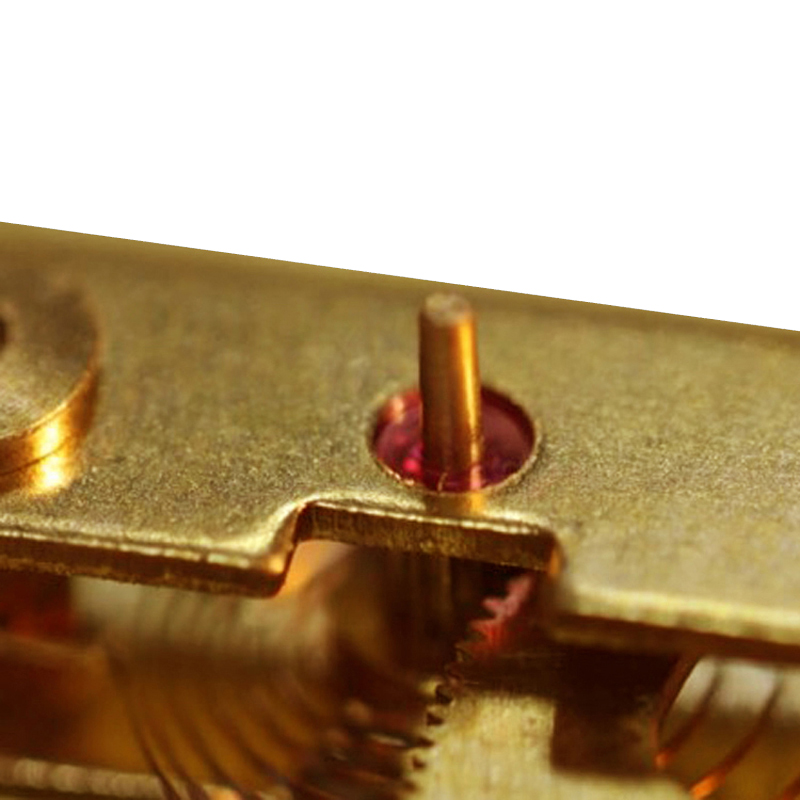

Wika, a renowned name in the instrumentation industry, has engineered its sanitary diaphragm pressure gauges to meet stringent hygiene and accuracy standards. These gauges typically feature a diaphragm that isolates the measuring element from the process media. Made from high-quality materials like stainless steel or other non-reactive alloys, the diaphragm is designed to withstand corrosive and abrasive substances.

One of the critical features of these gauges is their compliance with sanitary design standards, such as those defined by the FDA or EHEDG. This ensures that there are no areas where bacteria can accumulate, making them ideal for sanitary applications. Additionally, Wika diaphragm gauges are available with various connection options and can be customized to fit specific requirements, ensuring seamless integration into existing systems.

Advantages of Using Wika Sanitary Diaphragm Pressure Gauges

The use of Wika sanitary diaphragm pressure gauges presents several advantages. First and foremost is their reliability. These pressure gauges provide highly accurate readings, essential for maintaining optimal process conditions. The diaphragm mechanism allows for quick response times, which is crucial in dynamic environments where pressure levels can change rapidly.

Another significant advantage is their ability to function in extreme conditions. Wika pressure gauges are designed to handle high pressures and harsh environments, ensuring longevity and performance over time. The robust construction also minimizes the risk of leakage, adding an extra layer of safety to operations.

wika sanitary diaphragm pressure gauge exporter

Moreover, the sanitary design of these gauges simplifies cleaning and maintenance. With smooth surfaces and minimal crevices, they can be easily sanitized, reducing the risk of cross-contamination in sensitive applications like food processing and pharmaceuticals.

Applications in Various Industries

Wika sanitary diaphragm pressure gauges are widely used across different industries. In the food and beverage sector, they monitor the pressure of liquids in pipelines, ensuring consistent product quality and helping to maintain production efficiency. In breweries, for example, pressure gauges are critical during fermentation and carbonation processes.

In the pharmaceutical and biotechnology industries, the need for precision is even more pronounced. These gauges ensure that processes such as drug formulation, sterilization, and vaccine production operate within safe pressure ranges, thus adhering to strict regulatory requirements.

Additionally, the chemical industry also benefits from the use of Wika sanitary diaphragm gauges. These instruments can monitor the pressure of corrosive materials, ensuring that processes run smoothly without the risk of equipment failure.

Conclusion

In conclusion, Wika sanitary diaphragm pressure gauges play a vital role in ensuring accurate and reliable pressure measurement in various industrial applications. Their robust design, coupled with compliance to hygiene standards, makes them indispensable in sectors that require strict cleanliness and accuracy. By utilizing these advanced pressure gauges, industries can enhance operational safety, comply with regulatory standards, and improve overall efficiency. As technology continues to advance, the importance of such specialized instruments will only grow, making Wika an essential player in the field of industrial instrumentation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025