Nov . 19, 2024 02:10 Back to list

Exploring Renowned Diaphragm-Based Pressure Sensing Technologies and Their Applications

The Role of Diaphragms in Pressure Sensing Elements

Pressure sensing elements are fundamental components in various industrial applications, critical in measuring and monitoring pressure in fluids and gases. Among the various methodologies available for pressure sensing, diaphragm-based technologies have gained prominent recognition due to their accuracy, durability, and adaptability across different environments. This article explores the significance of diaphragms in pressure sensing elements, their operational principles, advantages, and common applications.

Understanding Pressure Sensing

Pressure sensors, also known as pressure transmitters or pressure transducers, convert pressure measurements into readable electrical signals. The mechanism works by detecting changes in pressure through deformable materials, which are often assisted by diaphragms. The diaphragm acts as a barrier – sensitive to pressure fluctuations – allowing for precise measurements while isolating the sensor from potentially harsh conditions.

Operating Principles of Diaphragm Pressure Sensors

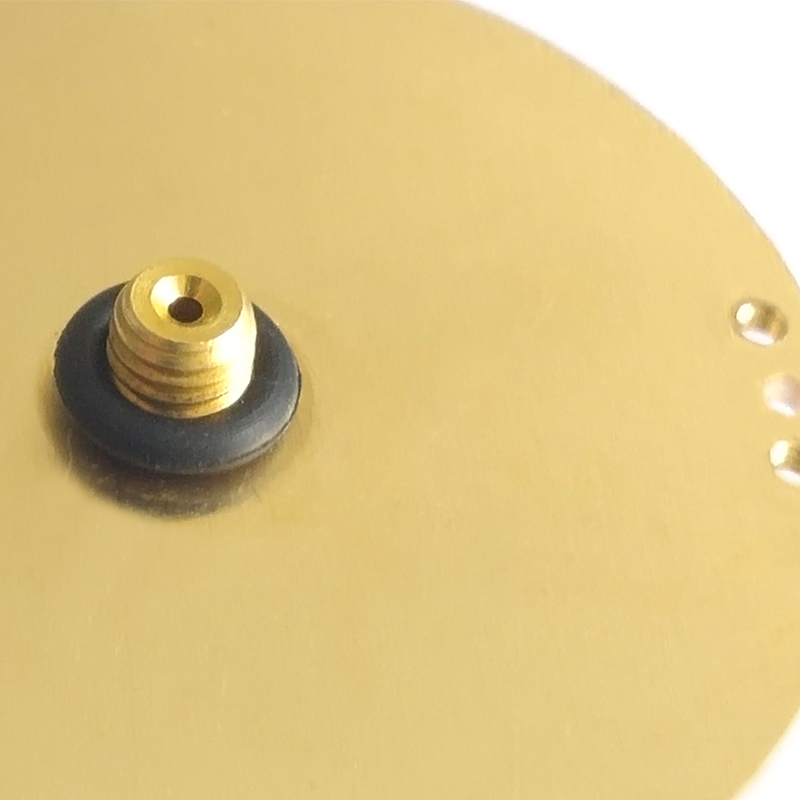

At the heart of diaphragm-based pressure sensors is the diaphragm itself, typically made from materials like stainless steel, silicon, or thin films of metals or polymers. When pressure is applied either on one side of the diaphragm (in absolute and gauge pressure sensors) or on both sides (in differential pressure sensors), the diaphragm deforms. This deformation is proportional to the pressure applied, thus creating a displacement that can be measured.

The change in shape of the diaphragm translates into a measurable electrical signal through various mechanisms, such as

1. Strain Gauges Strain gauges bonded to the diaphragm detect the small changes in resistance caused by its deformation. As pressure alters the diaphragm's shape, the resistance changes, and this can be converted into an electrical signal.

2. Capacitive Sensors In capacitive pressure sensors, the diaphragm acts as one plate of a capacitor. The change in gap distance between the diaphragm and a fixed plate alters the capacitance, which can be translated into pressure readings.

3. Piezoelectric Sensors These devices utilize materials that generate an electric charge in response to mechanical stress. The diaphragm's deformation produces an electrical output proportional to the applied pressure.

Regardless of the technology employed, the essential feature of diaphragm pressure sensors is the diaphragm's ability to respond accurately to pressure changes.

Advantages of Diaphragm-Based Sensors

Diaphragm pressure sensors offer several advantages that contribute to their widespread use

famous pressure sensing elements diaphragm

- High Accuracy Diaphragms provide a stable platform for measuring pressure, leading to highly precise readings.

- Durability Constructed from robust materials, diaphragm sensors withstand extreme conditions, including high pressures, corrosive environments, and temperature variations

.- Compact Design Many diaphragm pressure sensors are compact, making them suitable for installation in tight spaces where other sensor types may not fit.

- Versatility These sensors can be tailored for various applications, whether measuring gas, liquid, or vacuum pressure, making them indispensable in industries such as aerospace, automotive, and chemical processing.

Applications of Diaphragm Pressure Sensors

Diaphragm pressure sensors are employed in numerous applications across varied sectors

- Oil and Gas Monitoring wellhead pressures, drilling operations, and process control.

- Automotive Measuring fuel pressure, boost pressure in turbos, and manifold absolute pressure (MAP).

- Aerospace Used in hydraulic systems, altimeters, and environmental control systems.

- Medical Devices Monitoring pressure in respiratory equipment, patient monitoring systems, and infusion pumps.

- Industrial Automation Employed in process control systems, where accurate pressure measurements ensure safety and efficiency.

Conclusion

Diaphragms play an essential role in the functioning of pressure sensing elements. Their ability to convert mechanical deformation into reliable electrical signals underpins the precision and versatility of pressure sensors across numerous applications. As technology advances, the reliability and efficiency of diaphragm-based pressure sensors will continue to be vital, ensuring their importance in critical industrial processes and innovative technologies. Understanding these components equips engineers and professionals with the knowledge necessary to select and utilize pressure sensors effectively, improving overall system performance and reliability.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025