Jan . 14, 2025 10:29 Back to list

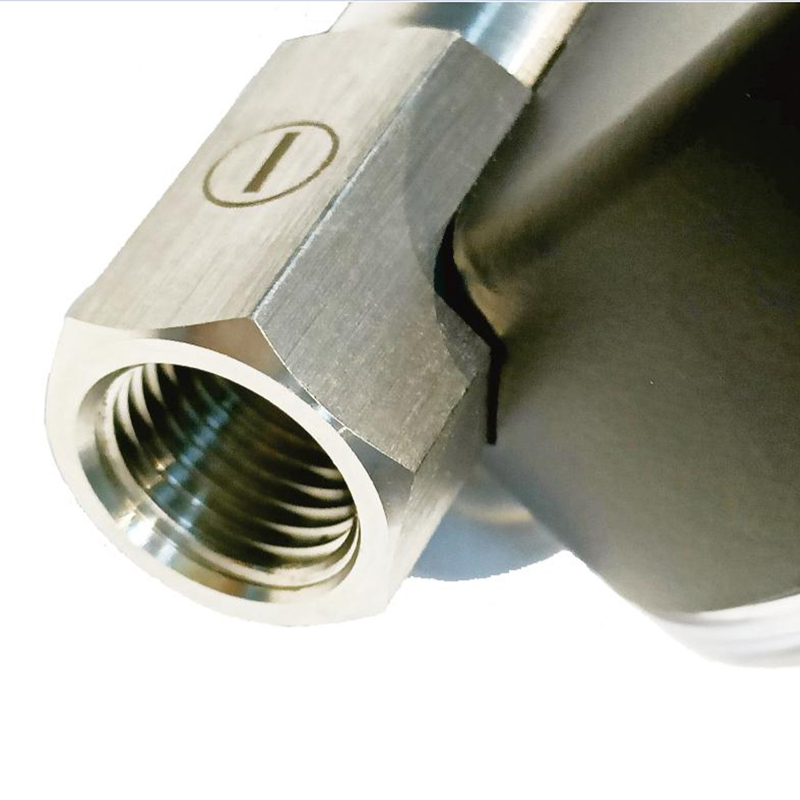

High purity pressure gauge(HPG,H- pressure) - VCR1/4" Female Face Seal Swivel / BA grade-10

Diaphragm protection pressure gauges are essential components in industries where rigorous conditions could compromise the performance and durability of standard pressure gauges. The precise engineering behind these devices ensures they operate seamlessly in scenarios involving corrosive, viscous, or crystallizing medium. Here, we delve into why diaphragm protection pressure gauges are indispensable, touching upon factors related to experience, expertise, authoritativeness, and trustworthiness.

Authoritativeness in diaphragm protection pressure gauges is often attributed to manufacturers with extensive histories in precision instrumentation. The credibility these manufacturers bring is built upon rigorous testing and a track record of providing reliable solutions in demanding environments. Accreditation to international standards, such as ISO and API certifications, further reinforces the authority these devices command in industrial applications. Such certifications ensure users can rely on these gauges for accurate readings, maintaining safety and efficiency within their systems. Trustworthiness is enhanced through comprehensive lifecycle support, from installation guidance to regular maintenance and calibration services. Leading manufacturers offer detailed documentation and expert assistance to ensure optimal performance. Moreover, diaphragm protection pressure gauges can be connected with advanced monitoring systems, allowing for real-time data access and predictive maintenance. This technological integration not only boosts trust but also forms the backbone of modern, automated process control systems, where reliability is paramount. In conclusion, diaphragm protection pressure gauges stand as a testament to advanced engineering, tailored to meet the rigorous demands of challenging industrial environments. The synergy between their design expertise, material resilience, authoritative backing, and reliable service support illustrates why these devices are indispensable for industries that prioritize both safety and operational efficiency. Their role in safeguarding process integrity and ensuring accurate pressure readings highlights their importance as an investment in long-term operational excellence.

Authoritativeness in diaphragm protection pressure gauges is often attributed to manufacturers with extensive histories in precision instrumentation. The credibility these manufacturers bring is built upon rigorous testing and a track record of providing reliable solutions in demanding environments. Accreditation to international standards, such as ISO and API certifications, further reinforces the authority these devices command in industrial applications. Such certifications ensure users can rely on these gauges for accurate readings, maintaining safety and efficiency within their systems. Trustworthiness is enhanced through comprehensive lifecycle support, from installation guidance to regular maintenance and calibration services. Leading manufacturers offer detailed documentation and expert assistance to ensure optimal performance. Moreover, diaphragm protection pressure gauges can be connected with advanced monitoring systems, allowing for real-time data access and predictive maintenance. This technological integration not only boosts trust but also forms the backbone of modern, automated process control systems, where reliability is paramount. In conclusion, diaphragm protection pressure gauges stand as a testament to advanced engineering, tailored to meet the rigorous demands of challenging industrial environments. The synergy between their design expertise, material resilience, authoritative backing, and reliable service support illustrates why these devices are indispensable for industries that prioritize both safety and operational efficiency. Their role in safeguarding process integrity and ensuring accurate pressure readings highlights their importance as an investment in long-term operational excellence.

Share

Latest news

-

Fluke Differential Pressure Gauges Precision Instruments for Industrial Use

NewsMay.25,2025

-

WIKA Differential Pressure Gauge 700.01 - High Accuracy & Durable Design

NewsMay.25,2025

-

Diaphragm Pressure Gauges High-Accuracy & Durable Solutions

NewsMay.25,2025

-

High-Accuracy Differential Pressure Gauge Diaphragms OEM Factories & Services

NewsMay.24,2025

-

Water Fire Extinguisher Pressure Gauge Durable Supplier Solutions

NewsMay.24,2025

-

Handheld Digital Differential Pressure Gauge Portable, High-Accuracy & Real-Time Data

NewsMay.24,2025