Oct . 31, 2024 06:19 Back to list

odm remote diaphragm seal pressure gauge

Understanding ODM Remote Diaphragm Seal Pressure Gauges

In the world of industrial instrumentation, pressure measurement plays a crucial role in ensuring operational efficiency and safety. One advanced solution that has gained popularity is the ODM remote diaphragm seal pressure gauge. This innovative device is designed to measure pressure in processes where direct contact with the medium is not feasible, providing both reliability and accuracy.

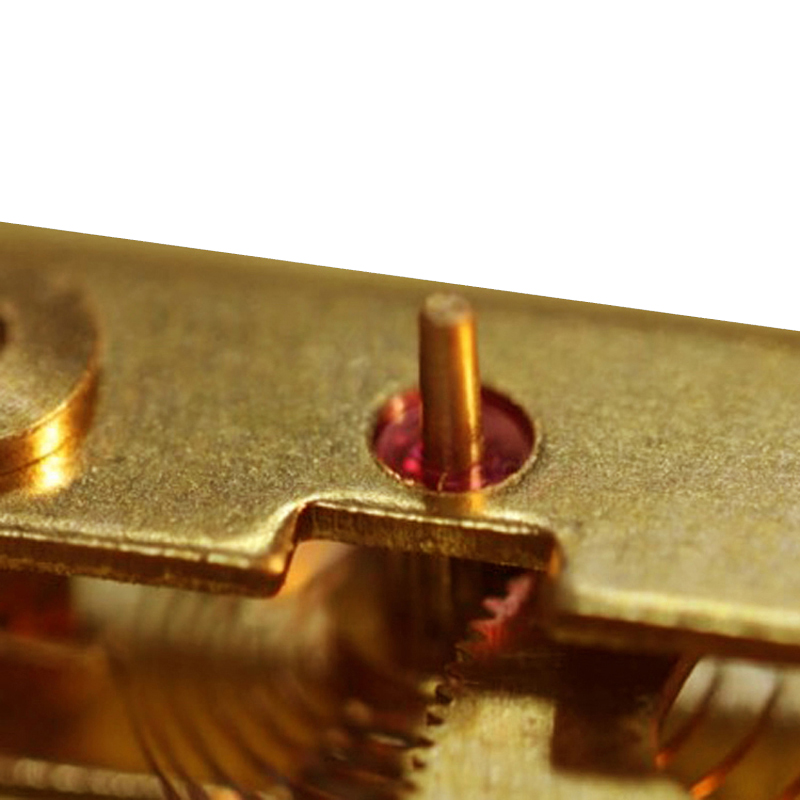

Remote diaphragm seal pressure gauges are particularly useful in applications involving corrosive or viscous fluids, high temperatures, or high-pressure environments. The design of these devices typically consists of a pressure gauge that is connected to a diaphragm seal via a capillary tube. The diaphragm acts as a barrier, isolating the pressure gauge from the process fluid. This isolation not only protects the gauge from damage but also prevents any contamination of the medium being measured.

One of the main advantages of using ODM remote diaphragm seal pressure gauges is their ability to handle various media without risking damage to the measurement device. For instance, in the chemical industry, harsh chemicals can destroy traditional pressure gauges, leading to inaccurate readings and potential safety hazards. By employing a diaphragm seal, operators can ensure accurate pressure readings while safeguarding the instrument.

odm remote diaphragm seal pressure gauge

Moreover, these gauges offer excellent performance even in extreme conditions. The diaphragm’s flexible design enables it to respond quickly to pressure changes while maintaining accuracy. Additionally, ODM remote diaphragm seals are available in various materials such as stainless steel, Hastelloy, and PTFE, catering to different process requirements. This versatility makes them suitable for a wide range of industries, including oil and gas, food and beverage, pharmaceuticals, and water treatment.

Installation and maintenance of ODM remote diaphragm seal pressure gauges are also user-friendly. The capillary tubes can be installed at varying lengths, allowing flexibility in design and installation without compromising performance. Regular maintenance is simplified as the diaphragm seals can be easily checked and serviced, ensuring prolonged instrument life and accuracy.

In conclusion, ODM remote diaphragm seal pressure gauges provide a robust solution for pressure measurement in challenging environments. By isolating the gauge from the media, these devices deliver reliable and accurate readings while preventing damage and contamination. Their versatility, performance under extreme conditions, and ease of maintenance make them an invaluable asset in various industrial applications. As industries continue to prioritize safety and efficiency, the adoption of remote diaphragm seal technology will undoubtedly grow, highlighting its significance in modern instrumentation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025