Jan . 30, 2025 01:14 Back to list

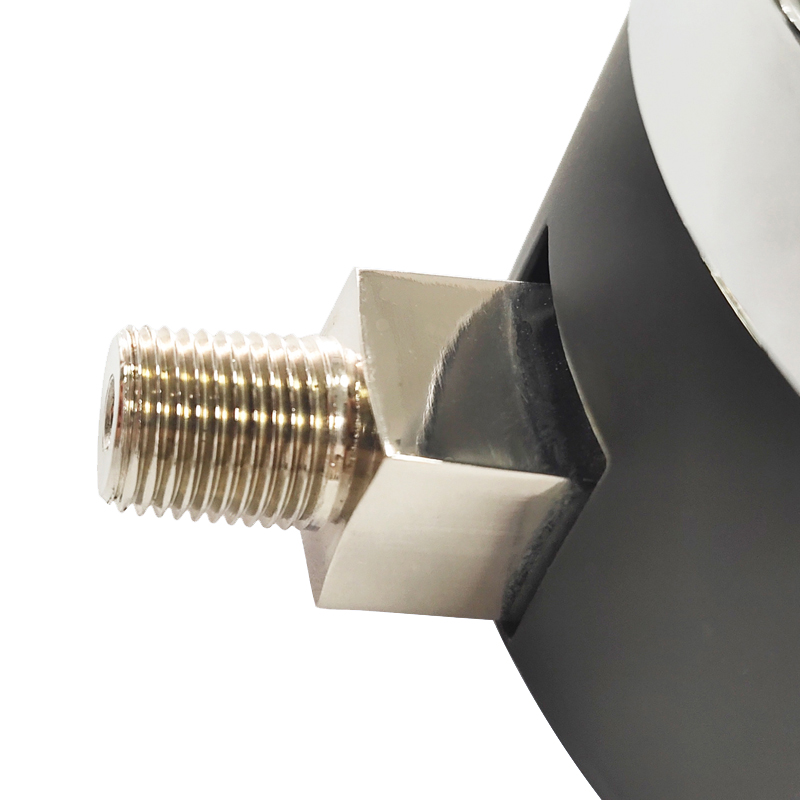

oem solid front differential pressure gauge

The OEM solid front differential pressure gauge is a specialized instrument designed to meet the rigorous demands of a variety of industrial applications. Recognized for its unwavering reliability, it stands as a superior choice for professionals seeking precision in pressure measurement. These gauges are specifically crafted for environments where safety, durability, and accuracy are vital.

For those specializing in safety and compliance, the OEM solid front differential pressure gauge doesn’t disappoint. Manufactured in compliance with stringent industry standards, these gauges meet and often exceed the necessary safety certifications. This compliance guarantees that the gauges are not only reliable but also safe to use in critical applications, fortifying their role as a trusted instrument in the field. Consultants and inspectors in the field frequently underline the importance of the gauge's user-friendly design. The easy-to-read dial reduces the possibility of human error in pressure reading, which can be pivotal in high-stress environments. Additionally, optional features such as overpressure protection and dampened movement mechanisms are available to further enhance the performance and safety of these instruments. Economically, investing in a high-quality OEM solid front differential pressure gauge can result in significant cost savings over time. While the initial investment might be substantial, the reduction in downtime, maintenance, and replacement costs ultimately justifies the expenditure. This long-term financial efficiency is a compelling factor for decision-makers aiming to optimize their operational budgets without compromising on quality or safety. In conclusion, the OEM solid front differential pressure gauge represents a perfect intersection of safety, precision, and durability. Its expertly crafted design, adherence to industry standards, and user-focused features make it an authoritative choice for professionals across various industries. Trust in a product is built on the consistent delivery of performance, and this gauge undoubtedly meets and exceeds expectations, thereby affirming its position as a trustworthy tool in any pressure-related application.

For those specializing in safety and compliance, the OEM solid front differential pressure gauge doesn’t disappoint. Manufactured in compliance with stringent industry standards, these gauges meet and often exceed the necessary safety certifications. This compliance guarantees that the gauges are not only reliable but also safe to use in critical applications, fortifying their role as a trusted instrument in the field. Consultants and inspectors in the field frequently underline the importance of the gauge's user-friendly design. The easy-to-read dial reduces the possibility of human error in pressure reading, which can be pivotal in high-stress environments. Additionally, optional features such as overpressure protection and dampened movement mechanisms are available to further enhance the performance and safety of these instruments. Economically, investing in a high-quality OEM solid front differential pressure gauge can result in significant cost savings over time. While the initial investment might be substantial, the reduction in downtime, maintenance, and replacement costs ultimately justifies the expenditure. This long-term financial efficiency is a compelling factor for decision-makers aiming to optimize their operational budgets without compromising on quality or safety. In conclusion, the OEM solid front differential pressure gauge represents a perfect intersection of safety, precision, and durability. Its expertly crafted design, adherence to industry standards, and user-focused features make it an authoritative choice for professionals across various industries. Trust in a product is built on the consistent delivery of performance, and this gauge undoubtedly meets and exceeds expectations, thereby affirming its position as a trustworthy tool in any pressure-related application.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025