Dec . 09, 2024 16:14 Back to list

Suppliers of Sealed Diaphragm Pressure Gauges for Accurate Measurement

Sealed Diaphragm Pressure Gauge Supplier Ensuring Accurate Measurement for Critical Applications

In the world of industrial measurement, precision and reliability are paramount. Pressure gauges are essential instruments used to measure the pressure of gases and liquids in various applications, from manufacturing and processing to HVAC systems and automotive engineering. Among the different types of pressure gauges available, sealed diaphragm pressure gauges have garnered significant attention due to their unique features and advantages. To meet the growing demand for accurate pressure measurement, finding a reputable supplier of sealed diaphragm pressure gauges is crucial.

Understanding Sealed Diaphragm Pressure Gauges

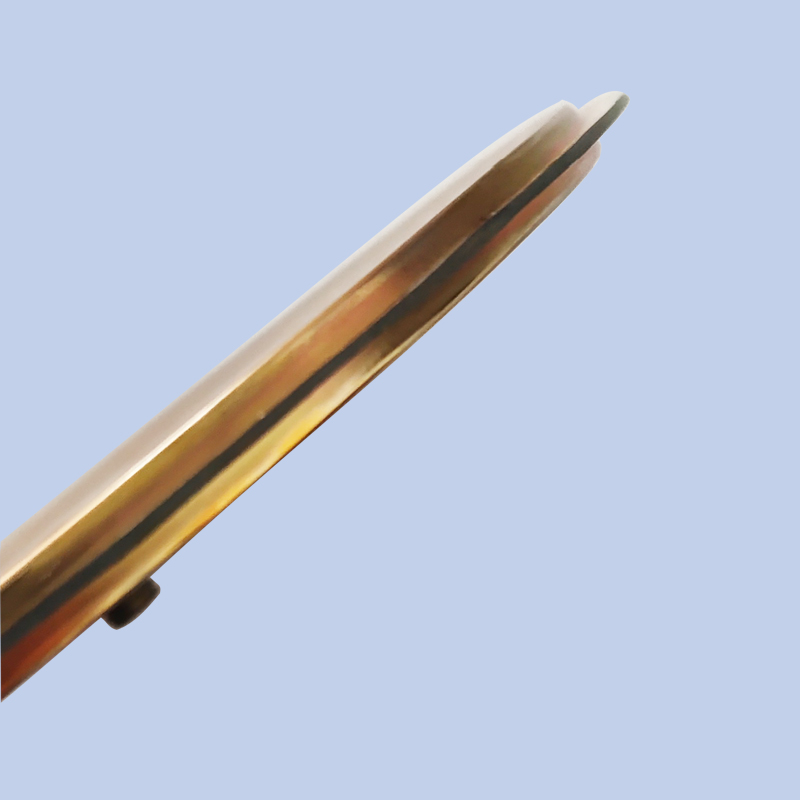

Sealed diaphragm pressure gauges consist of a sensing element (the diaphragm) that deforms in response to pressure changes. This deformation is translated into a movement that indicates the pressure reading on a calibrated dial. The sealed aspect refers to an isolating barrier that protects the gauge from the medium being measured, preventing contamination and ensuring longevity.

These gauges are particularly useful in environments where the process media could be corrosive, viscous, or contain particulates that may damage traditional pressure gauges. The sealing feature allows for more extensive applications, including chemical processing, food and beverage production, and water treatment.

Benefits of Using Sealed Diaphragm Pressure Gauges

1. Corrosion Resistance With the diaphragm and internal components made from materials such as stainless steel, these gauges can withstand harsh environments, allowing them to function effectively in corrosive media.

2. Low Maintenance The sealed design minimizes the need for regular maintenance and calibration, reducing downtime and maintenance costs.

4. Versatility These gauges can handle various media types and are adaptable to different installation requirements, further enhancing their usability across multiple industries.

sealed diaphragm pressure gauge supplier

Choosing the Right Supplier

When seeking a supplier for sealed diaphragm pressure gauges, several factors should be considered to ensure that the selection meets the specific needs of the application

1. Reputation Research potential suppliers to assess their reputation in the market. Look for customer reviews, testimonials, and case studies that reflect the quality of their products and services.

2. Product Range A reliable supplier should offer a wide variety of sealed diaphragm gauges to accommodate different pressure ranges, sizes, and material specifications. This diversity ensures that clients can find the perfect fit for their specific applications.

3. Technical Support A good supplier will provide technical assistance, helping clients choose the right gauge and addressing any questions about installation, maintenance, and calibration.

4. Quality Assurance Check if the supplier adheres to industry standards and certifications. This ensures that the gauges are manufactured using best practices and maintain consistent quality.

5. Warranty and After-Sales Service A reputable supplier will offer a warranty for their products and provide after-sales support, further instilling confidence in the quality and reliability of their gauges.

Conclusion

In industries where precision and reliability are crucial, sealed diaphragm pressure gauges hold an essential role in monitoring and controlling pressure levels. Finding a trusted supplier of these specialized measuring instruments can significantly impact the efficiency and safety of operations. By considering factors such as reputation, product range, technical support, quality assurance, and warranty, businesses can ensure that they obtain high-quality sealed diaphragm pressure gauges suitable for their specific applications. Investing in reliable measurement solutions not only enhances productivity but also contributes to the overall success of industrial operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025