Aug . 07, 2024 17:00 Back to list

Tailored Differential Pressure Gauge Solutions for Optimal Performance in Diverse Applications

Customized Differential Pressure Gauge A Comprehensive Overview

In various industrial applications, the ability to accurately measure and monitor pressure differences is crucial for ensuring operational efficiency, safety, and compliance with regulatory standards. This need has led to the evolution of specialized instruments, such as the customized differential pressure gauge. This article delves into the significance, design considerations, and applications of these gauges, underscoring their importance in diverse sectors.

Understanding Differential Pressure Gauges

A differential pressure gauge is an instrument that measures the difference in pressure between two points in a system. Unlike standard gauges that measure absolute or gauge pressure, these devices are specifically designed to provide more detailed insights into pressure variations. This capability is essential in processes where differential pressure plays a pivotal role, such as filtration systems, HVAC applications, and process automation.

The Importance of Customization

The term customized implies that these gauges can be tailored to meet specific requirements of end-users. The customization can encompass various aspects, including

1. Measurement Range Different applications require gauges to operate within specified pressure ranges. Customized gauges can be designed to handle high or low differential pressures based on the application’s demands.

2. Material Selection Depending on the environment, the materials used for the gauge housing and internal components may vary. Customized solutions allow for the selection of materials that withstand corrosive substances, extreme temperatures, or other harsh conditions.

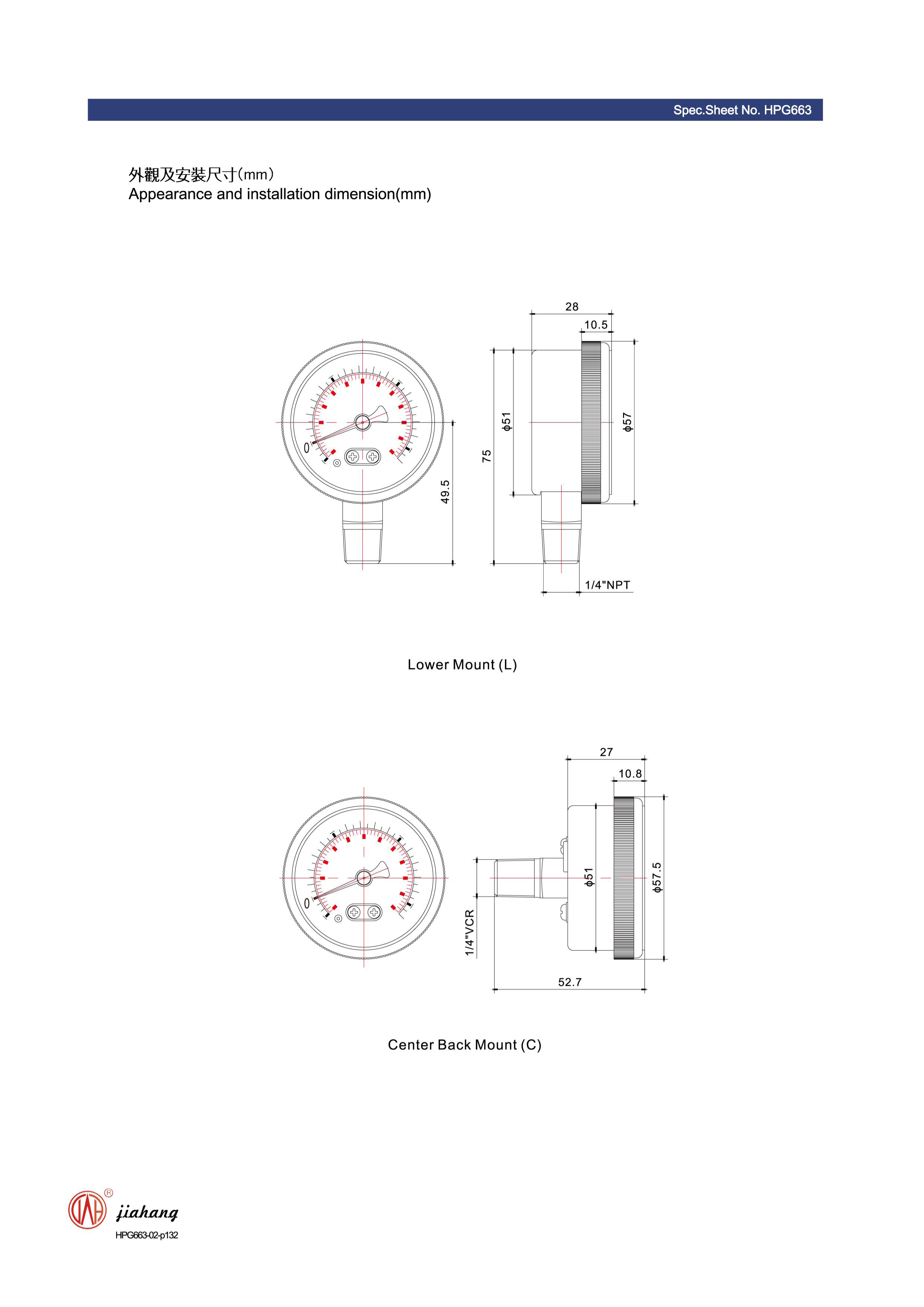

3. Connection Types The ability to customize connection types ensures compatibility with existing systems. Whether it’s threaded, flanged, or sanitary connections, tailored designs can accommodate specific installation needs.

4. Display Options Users may require different display features, such as analog versus digital readouts, or specific calibration settings. Customization allows for the choice of display that aligns with user preferences and operational requirements.

customized differential pressure gauge product

5. Integration Features For advanced applications, integrating the gauge with existing monitoring and control systems can enhance functionality. Custom solutions can include electronic outputs or communication protocols for seamless integration.

Applications Across Industries

Customized differential pressure gauges find applications across various sectors, including

1. HVAC Systems In heating, ventilation, and air conditioning, maintaining optimal airflow is crucial. Differential pressure gauges help monitor filter conditions and airflow dynamics, ensuring system efficiency and longevity.

2. Pharmaceuticals and Biotechnology In regulated industries, precise pressure measurements are vital for quality control. Customized gauges enable accurate monitoring of filtration processes and upstream/downstream pressure variations in critical systems.

3. Oil and Gas Differential pressure gauges are essential in monitoring pressure drops across separators, filters, and pipelines. Custom solutions are engineered to withstand the harsh conditions prevalent in oil and gas exploration and production.

4. Water and Wastewater Management These gauges play a critical role in managing water treatment processes. By monitoring pressure differentials across filters and pumps, operators can maintain system efficiency and prevent failures.

5. Chemical Processing In chemical manufacturing, maintaining the correct pressure balance is essential for safety and product quality. Customized gauges provide the necessary precision to monitor and control pressure differentials continuously.

Conclusion

The customized differential pressure gauge is an invaluable tool across multiple industries. Its ability to provide precise measurements tailored to specific conditions makes it an essential component of modern industrial operations. As technology continues to evolve, the demand for customized solutions will undoubtedly grow, leading to further innovations in design and functionality. By investing in quality, customized differential pressure gauges, industries can enhance their process control, ensure safety, and improve overall system efficiency.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025