Jul . 03, 2024 02:00 Back to list

Understanding the Components and Function of a Diaphragm Pressure Gauge

Understanding the Parts and Function of a Diaphragm Pressure Gauge

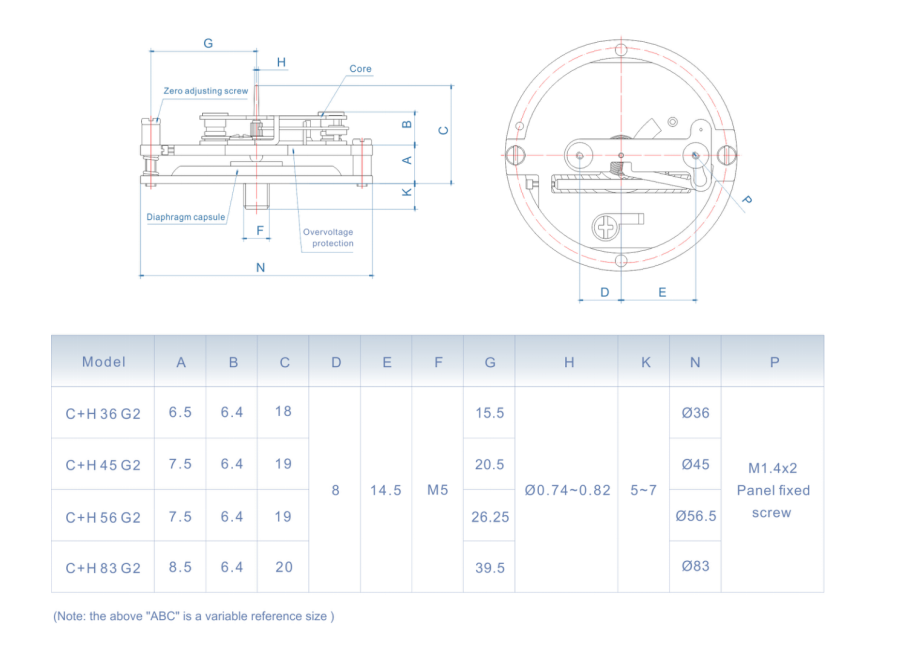

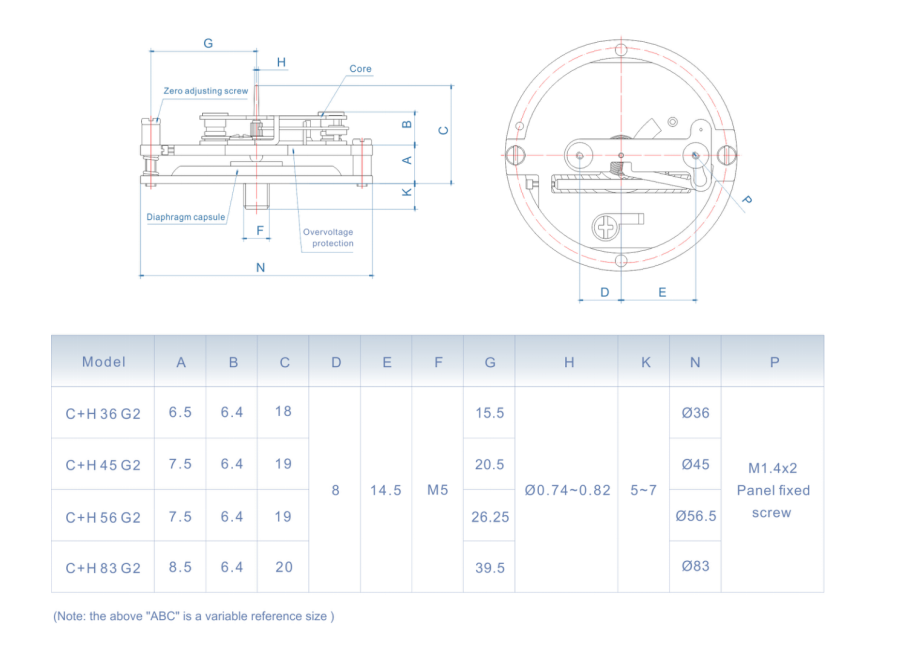

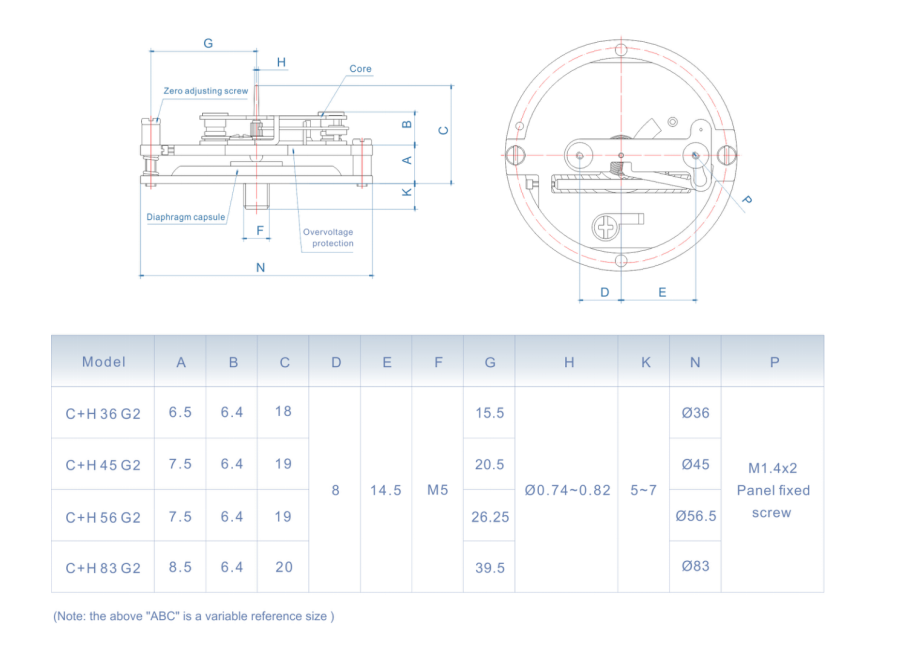

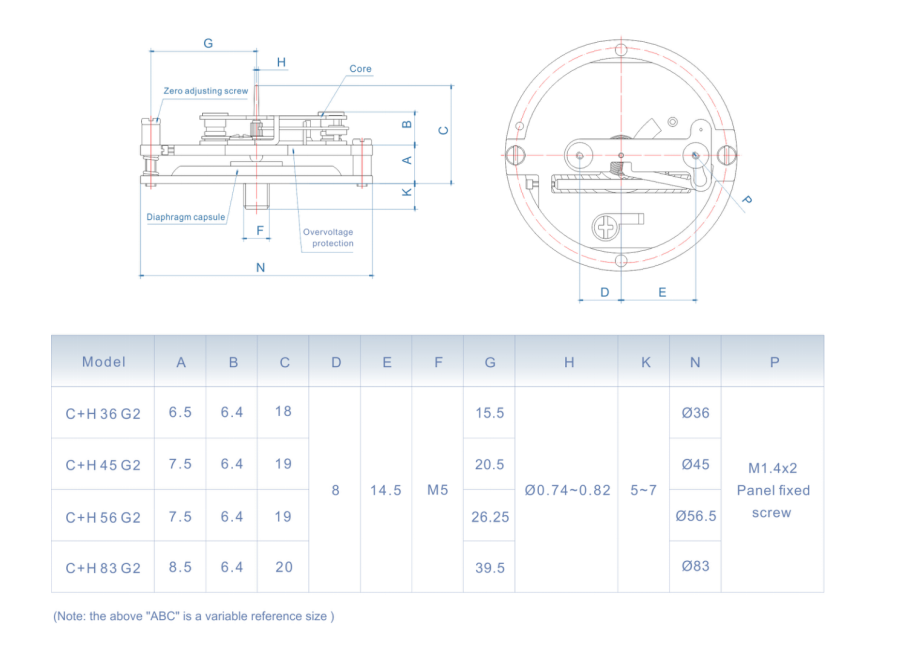

A diaphragm pressure gauge is an essential tool in various industries, particularly in those that deal with precise pressure measurements. It operates on the principle of a flexible diaphragm that deforms in response to applied pressure, translating this deformation into a readable output. This article will delve into the key components of a diaphragm pressure gauge and their roles in ensuring accurate pressure measurement.

Firstly, the diaphragm itself is the core element of the gauge. Made from materials like stainless steel or Monel, it serves as a sensitive barrier between the measured medium and the internal mechanism. The diaphragm's flexibility allows it to change shape when subjected to pressure, thus creating a measurable displacement.

The housing of the gauge is another critical part. It is designed to be robust and resistant to corrosion, protecting the internal components from environmental influences. It also houses the connection ports, which allow the gauge to be attached to the system where pressure needs to be measured.

The measuring mechanism lies at the heart of the gauge. It typically includes a Bourdon tube or a bellows, which respond to the diaphragm's movement. As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial

As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial parts of diaphragm pressure gauge.

The bourdon tube, if present, is a coiled metal tube that straightens as the pressure changes, causing a rotation of a gear system that moves the pointer on the dial. Alternatively, bellows, similar to the diaphragm, change shape under pressure, driving the pointer via a mechanical linkage.

The pointer and dial are the visual elements of the gauge. The dial is marked with numerical values indicating the pressure range, while the pointer indicates the current pressure reading. For clarity, often, different color zones are used for low, medium, and high-pressure ranges.

Lastly, the bourdon tube or bellows is connected to the diaphragm through a threaded connection or a compression fitting. This interface is critical as it transmits the diaphragm's motion accurately without loss or distortion.

In conclusion, the diaphragm pressure gauge's functionality is a result of the harmonious interaction between its components. Each part plays a specific role, from the diaphragm sensing the pressure to the pointer indicating the reading. Understanding these parts and their functions is vital for proper usage, maintenance, and interpretation of readings, ensuring reliable performance in various industrial applications.

parts of diaphragm pressure gauge.

The bourdon tube, if present, is a coiled metal tube that straightens as the pressure changes, causing a rotation of a gear system that moves the pointer on the dial. Alternatively, bellows, similar to the diaphragm, change shape under pressure, driving the pointer via a mechanical linkage.

The pointer and dial are the visual elements of the gauge. The dial is marked with numerical values indicating the pressure range, while the pointer indicates the current pressure reading. For clarity, often, different color zones are used for low, medium, and high-pressure ranges.

Lastly, the bourdon tube or bellows is connected to the diaphragm through a threaded connection or a compression fitting. This interface is critical as it transmits the diaphragm's motion accurately without loss or distortion.

In conclusion, the diaphragm pressure gauge's functionality is a result of the harmonious interaction between its components. Each part plays a specific role, from the diaphragm sensing the pressure to the pointer indicating the reading. Understanding these parts and their functions is vital for proper usage, maintenance, and interpretation of readings, ensuring reliable performance in various industrial applications.

As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial

As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial As the diaphragm deforms due to pressure, it transfers this motion to the measuring mechanism, which in turn converts it into a readable indication on the dial parts of diaphragm pressure gauge.

The bourdon tube, if present, is a coiled metal tube that straightens as the pressure changes, causing a rotation of a gear system that moves the pointer on the dial. Alternatively, bellows, similar to the diaphragm, change shape under pressure, driving the pointer via a mechanical linkage.

The pointer and dial are the visual elements of the gauge. The dial is marked with numerical values indicating the pressure range, while the pointer indicates the current pressure reading. For clarity, often, different color zones are used for low, medium, and high-pressure ranges.

Lastly, the bourdon tube or bellows is connected to the diaphragm through a threaded connection or a compression fitting. This interface is critical as it transmits the diaphragm's motion accurately without loss or distortion.

In conclusion, the diaphragm pressure gauge's functionality is a result of the harmonious interaction between its components. Each part plays a specific role, from the diaphragm sensing the pressure to the pointer indicating the reading. Understanding these parts and their functions is vital for proper usage, maintenance, and interpretation of readings, ensuring reliable performance in various industrial applications.

parts of diaphragm pressure gauge.

The bourdon tube, if present, is a coiled metal tube that straightens as the pressure changes, causing a rotation of a gear system that moves the pointer on the dial. Alternatively, bellows, similar to the diaphragm, change shape under pressure, driving the pointer via a mechanical linkage.

The pointer and dial are the visual elements of the gauge. The dial is marked with numerical values indicating the pressure range, while the pointer indicates the current pressure reading. For clarity, often, different color zones are used for low, medium, and high-pressure ranges.

Lastly, the bourdon tube or bellows is connected to the diaphragm through a threaded connection or a compression fitting. This interface is critical as it transmits the diaphragm's motion accurately without loss or distortion.

In conclusion, the diaphragm pressure gauge's functionality is a result of the harmonious interaction between its components. Each part plays a specific role, from the diaphragm sensing the pressure to the pointer indicating the reading. Understanding these parts and their functions is vital for proper usage, maintenance, and interpretation of readings, ensuring reliable performance in various industrial applications. Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025