Aug . 13, 2024 13:42 Back to list

Understanding the Functionality and Applications of OEM Span Differential Pressure Gauges in Industry

Understanding OEM Span Differential Pressure Gauges

Differential pressure gauges play a pivotal role in various industrial applications, serving as essential instruments for measuring the difference in pressure between two points in a system. Among the various types of differential pressure gauges available, OEM span differential pressure gauges stand out due to their unique design and operational efficiencies tailored for original equipment manufacturers (OEMs). This article will delve into the significance, functionality, and applications of OEM span differential pressure gauges.

What is a Differential Pressure Gauge?

In simple terms, a differential pressure gauge is a device that measures the pressure differential between two points in a system. This kind of gauge is crucial in processes where maintaining the correct pressure balance is vital for safe and efficient operations. For OEMs, having precise and reliable measurement instruments is crucial to ensuring equipment performance and longevity.

The Importance of OEM Span Differential Pressure Gauges

OEM span differential pressure gauges are specifically designed for integration into various manufacturing processes and equipment. The term span refers to the operational range of the gauge, indicating the maximum and minimum pressures it can measure. The importance of these gauges lies in their ability to provide accurate and consistent readings, which are critical for monitoring system performance, preventing equipment failures, and optimizing processes.

1. Accuracy and Reliability OEM span differential pressure gauges are engineered to deliver precise measurements, which helps in ensuring that processes operate within designated parameters. Reliable readings are essential for troubleshooting, predictive maintenance, and overall system efficiency.

2. Customization for Specific Applications As OEMs often cater to diverse industries with unique requirements, span differential pressure gauges can be customized to meet specific operational needs. This adaptability makes them invaluable in various sectors, including oil and gas, pharmaceuticals, food and beverage, and water treatment.

3. Integration Capabilities These gauges are designed for seamless integration into existing systems. Utilizing standard mounting options and interfaces allows for easy installation and connection to control systems, ensuring minimal disruption during setup.

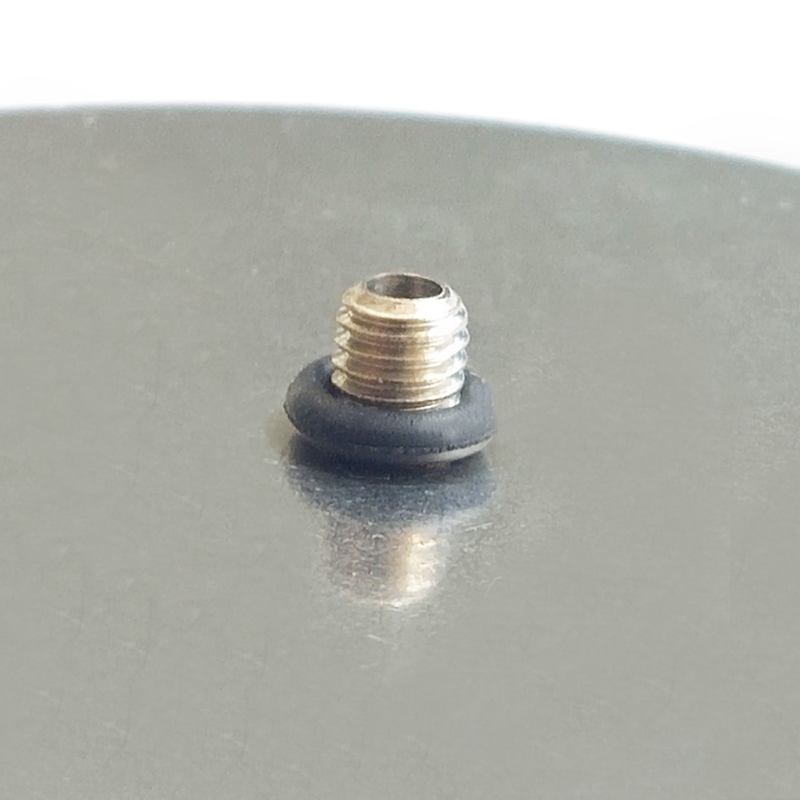

oem span differential pressure gauge

Applications of OEM Span Differential Pressure Gauges

The application of OEM span differential pressure gauges spans across numerous industries and operational contexts. Here are a few notable examples

- HVAC Systems In heating, ventilation, and air conditioning systems, these gauges are used to monitor filter pressures, ensuring airflow efficiency and system reliability.

- Process Control In chemical manufacturing, differential pressure gauges are essential for monitoring pipe blockages, pump performance, and reactor pressures, allowing for optimized production.

- Wastewater Treatment These gauges help in maintaining proper flow rates and pressure differentials in treatment systems, ensuring effective waste management.

- Pharmaceutical Manufacturing In the production of medicines and medical devices, maintaining precise pressure levels is vital for product safety and regulatory compliance. OEM span differential pressure gauges ensure that these standards are met.

Conclusion

OEM span differential pressure gauges are indispensable tools in modern industrial environments, offering accuracy, customization, and reliability. As industries continue to evolve and demand greater precision in their processes, the role of these gauges will only become more pronounced. For manufacturers and operators seeking to enhance their equipment's performance and efficiency, investing in high-quality OEM span differential pressure gauges is a wise choice that pays dividends in both safety and productivity. As technology advances, we can expect further innovations in these measurement tools, making them even more effective in meeting the challenges of the future.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025