Dec . 11, 2024 18:34 Back to list

accessories of pressure gauge factories

Accessories of Pressure Gauge Factories Ensuring Precision and Performance

Pressure gauges are vital instruments used across various industries to measure the pressure of gases or liquids. Accurate pressure measurement is critical for ensuring safety, efficiency, and performance in processes ranging from manufacturing to HVAC systems. However, the effectiveness of a pressure gauge does not solely depend on the gauge itself; a variety of accessories play a crucial role in enhancing its performance and reliability. This article explores the key accessories used in pressure gauge factories and their importance.

Calibrating pressure gauges is paramount for maintaining accuracy. Pressure calibration pumps are specialized devices that generate precise pressure levels for testing pressure gauges. These pumps can create both positive and negative pressures, allowing technicians to verify the functionality of the gauge across its entire measurement range. By employing these calibration pumps, factories ensure that their pressure gauges provide accurate readings, which is essential for quality control and compliance with industry standards.

2. Pressure Calibrators

Similar to calibration pumps, pressure calibrators are advanced tools that allow for the precise measurement and adjustment of pressure readings. These devices often come equipped with digital displays and can store multiple pressure readings for comparative analysis. By integrating pressure calibrators in the production process, factories can achieve heightened accuracy in their pressure gauges, leading to better overall product quality.

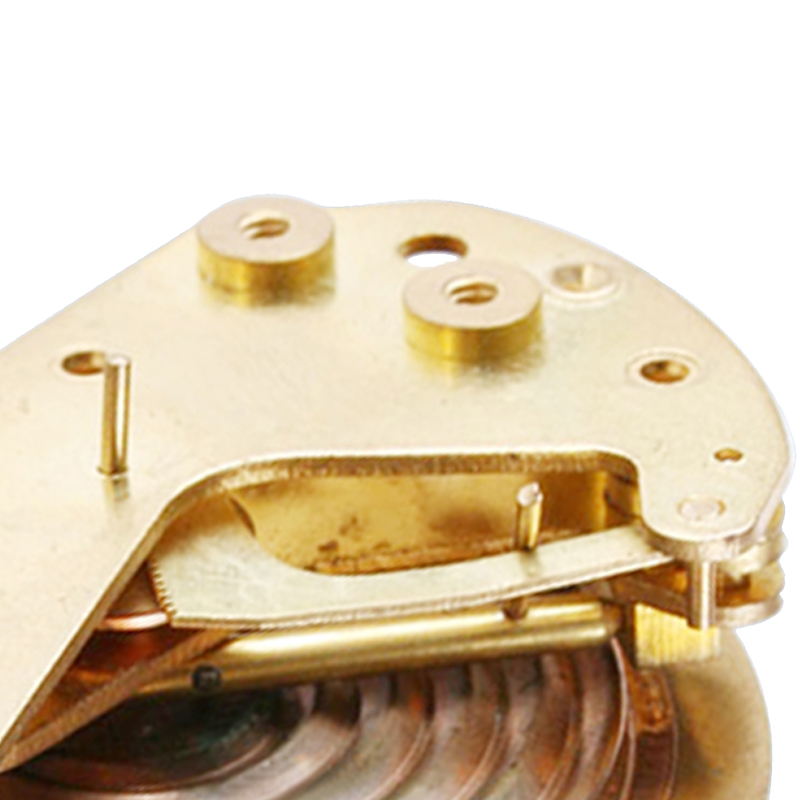

3. Adapters and Connectors

The versatility of pressure gauges is significantly enhanced by the use of adapters and connectors. These accessories allow pressure gauges to be installed in various configurations and environments. They help facilitate connections between the pressure gauge and the piping or systems it needs to measure. Employing high-quality adapters and connectors ensures a leak-proof seal and minimizes the chances of damage during installation. This not only protects the gauges but also enhances the accuracy of readings by ensuring proper measurements are taken from the intended source.

4. Isolation Valves

accessories of pressure gauge factories

Isolation valves are crucial accessories that offer various benefits during the operation of pressure gauges. These valves allow technicians to isolate the gauge from the system without disrupting the entire process. For example, if a gauge requires maintenance or replacement, the isolation valve can be closed, preventing fluid from flowing into the gauge. This minimizes downtime and enhances safety, as technicians can work on the gauge without the risk of pressure release or fluid spillage. Incorporating isolation valves in installations significantly contributes to the longevity and reliability of pressure measurement systems.

5. Protective Covers and Cases

While pressure gauges are built to endure harsh conditions, protective covers and cases offer an additional layer of safety. These accessories shield gauges from environmental factors, including dust, moisture, and physical impacts. In demanding industrial environments, having durable protective covers can prolong the lifespan of gauges and reduce maintenance needs. This, in turn, leads to lower costs and increased reliability in pressure measurement.

6. Mounting Brackets

Proper installation of pressure gauges is essential for achieving accurate readings. Mounting brackets provide the necessary support to ensure that gauges are securely fastened in place. This prevents movement that could lead to erroneous measurements or damage to the gauge itself. Investing in high-quality mounting solutions ensures that the gauges remain aligned and functional, even in high-vibration environments.

7. Data Logging Devices

In today's data-driven world, monitoring pressure readings over time has become increasingly valuable. Data logging devices can be paired with pressure gauges to collect and store data for analysis. This capability allows factories to track trends, monitor performance, and identify potential issues before they escalate. By leveraging data logging technology, companies can enhance predictive maintenance strategies and optimize their operations.

Conclusion

Accessories of pressure gauge factories play a crucial role in ensuring that pressure measurement systems work efficiently and accurately. From calibration tools to protective gear, each accessory contributes to the reliability and performance of pressure gauges. As industries continue to evolve and demand greater precision, investing in high-quality accessories will be paramount for manufacturers aiming to maintain competitive advantages and uphold safety standards. Understanding and utilizing these accessories is essential for every factory looking to enhance the integrity of their pressure measurement processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025