Oct . 08, 2024 19:15 Back to list

Differential Pressure Gauge Manufacturer and Supplier for Industrial Applications

The Importance of Differential Pressure Gauges in Industrial Applications

In various industrial processes, maintaining optimal conditions is crucial for efficiency, safety, and productivity. One vital instrument that plays a significant role in these processes is the differential pressure gauge. This device measures the difference in pressure between two points in a system, offering critical insights into the performance of equipment and systems.

Differential pressure gauges are widely used in industries such as oil and gas, water treatment, pharmaceuticals, and HVAC systems. They help monitor pressure variations in filters, pumps, and pipelines, ensuring that the processes run smoothly. For instance, in a filtration system, a differential pressure gauge can indicate when a filter is becoming clogged. By monitoring the pressure drop across the filter, operators can determine the optimal time for maintenance, thus preventing equipment failure and unscheduled downtime.

One of the key advantages of differential pressure gauges is their ability to provide real-time data. This immediacy allows operators to make quick decisions to adjust operations as needed. Moreover, these gauges can enhance safety by identifying abnormal pressure conditions that may indicate leaks or blockages, allowing for prompt corrective action.

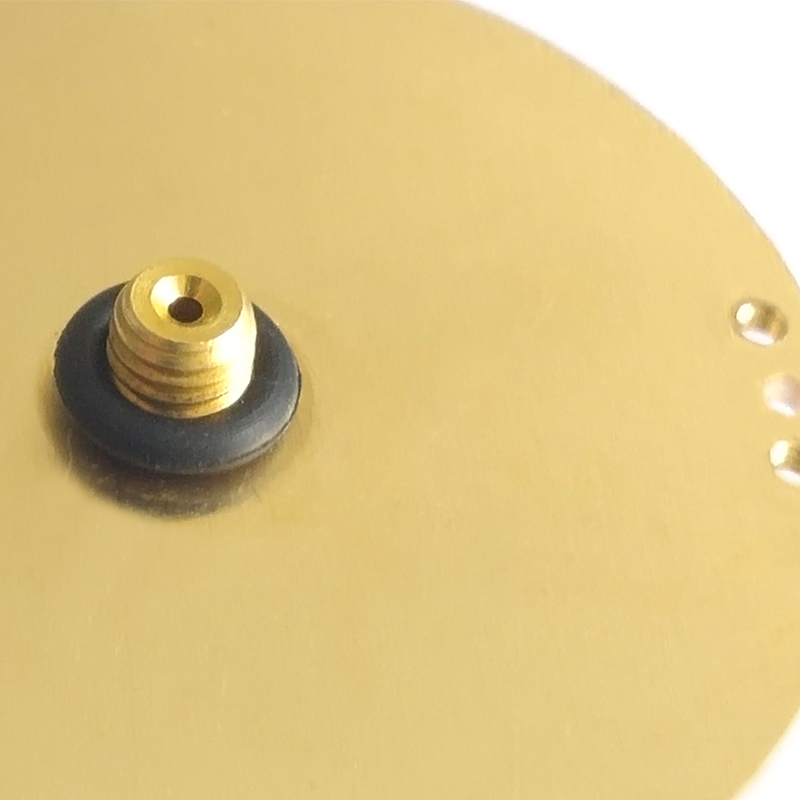

bellow differential pressure gauge factory

Manufacturers of differential pressure gauges focus on precision and reliability. High-quality gauges are designed to withstand harsh environments, including extreme temperatures and corrosive materials. Advanced technologies, such as digital displays and wireless transmission, further improve their functionality by offering enhanced accuracy and convenience for data monitoring.

In addition, the installation and calibration of differential pressure gauges are critical to their performance. Proper installation ensures accurate readings and reliability, while regular calibration is necessary to maintain precision over time. Factories that prioritize these aspects often find significant improvements in operational efficiency and safety.

As industries continue to evolve, the demand for accurate and reliable measurement tools like differential pressure gauges will grow. Their essential role in monitoring and control makes them indispensable in ensuring that industrial processes operate within desired parameters. Manufacturers committed to innovation and quality will lead the way in providing the next generation of differential pressure gauges, helping industries achieve greater efficiency and safety in their operations.

In conclusion, differential pressure gauges are essential instruments in the industrial landscape, providing valuable data that supports optimal performance and safety across various applications.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025