Sep . 07, 2024 14:01 Back to list

Best Pressure Gauge Diaphragm Type - Reliable Measurement Solutions

Understanding the Best Pressure Gauge Diaphragm Type

Pressure gauges are essential instruments used across various industries to measure and monitor pressure levels in different settings, from manufacturing processes to laboratory experiments. Among the various types of pressure gauges, the diaphragm type stands out for its accuracy and reliability, making it a popular choice for numerous applications. This article explores the features that distinguish diaphragm-type pressure gauges and why they might be the best choice for your needs.

What is a Diaphragm Pressure Gauge?

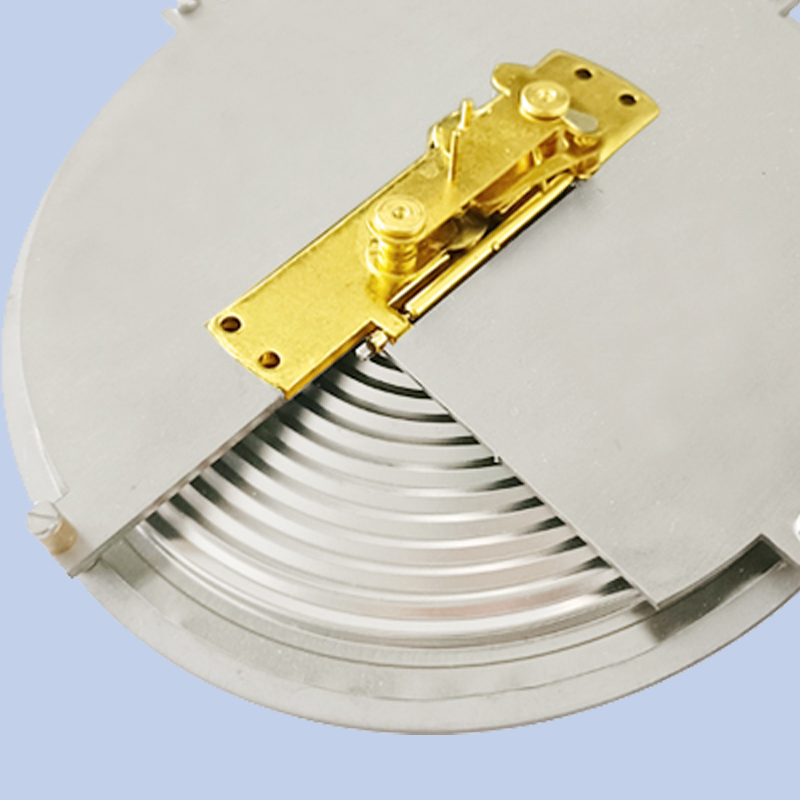

The diaphragm pressure gauge operates using a flexible element, typically a diaphragm, which deflects in response to the pressure applied to it. This deflection translates into a measurable movement that can be converted into a readable pressure value. The design of diaphragm gauges allows them to withstand high pressures while maintaining accuracy, making them ideal for various applications, including oil and gas, pharmaceuticals, and food processing.

Key Features and Benefits

1. Accuracy and Precision Diaphragm pressure gauges offer a high level of accuracy, often providing readings within 1% of full-scale value. This precision is crucial in industrial settings where even slight pressure variations can lead to faulty operations or safety concerns.

2. Wide Pressure Range These gauges are suitable for measuring a wide range of pressures, from low vacuum levels to high-pressure outputs. Various diaphragm materials enable the gauges to function effectively across diverse conditions, including differing temperatures and corrosive environments.

best pressure gauge diaphragm type

3. Robust Design The construction of diaphragm gauges helps them resist pulsation and vibration, common in many industrial environments. This robustness translates into longer service life and reduced maintenance needs, making them a cost-effective choice for businesses.

4. Versatility Diaphragm pressure gauges are versatile instruments used in many industries. Whether monitoring gas pressure in pipelines, measuring fluid pressure in tanks, or ensuring safety in HVAC systems, these gauges can be adapted to a myriad of applications.

5. Ease of Installation and Use Typically, diaphragm pressure gauges are user-friendly, with straightforward installation procedures and easy-to-read dials. Many models come equipped with features like adjustable zero and range settings, further enhancing their usability in various contexts.

Applications

Diaphragm pressure gauges find their place in numerous applications. In the oil and gas sector, they monitor pipeline pressures to prevent leaks and ensure safety. In the pharmaceutical industry, they are instrumental in maintaining the correct pressure levels in reaction vessels. Additionally, they are widely used in HVAC systems for monitoring pressure changes, ensuring systems operate efficiently.

Conclusion

The diaphragm-type pressure gauge is often regarded as the best choice for those seeking a reliable and accurate pressure monitoring solution. Its robust design, impressive accuracy, and versatility across various applications make it indispensable in many industrial processes. If you are considering upgrading your monitoring instruments or investing in new ones, diaphragm pressure gauges should be at the forefront of your consideration. With their exceptional performance, they can significantly contribute to the operational efficiency and safety of your processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025