Nov . 08, 2024 03:31 Back to list

Top Quality Precision Instruments for Accurate Pressure Measurement Solutions

The Best Precision Instruments A Focus on Pressure Gauges

In the realm of industrial and scientific applications, precise measurement is crucial. Among the myriad of instruments that facilitate accurate readings, pressure gauges stand out due to their essential role in monitoring and controlling pressure within systems. This article delves into the world of pressure gauges, highlighting their types, applications, and the best practices for selecting high-precision instruments.

Understanding Pressure Gauges

A pressure gauge is a device used to measure the pressure of gases or liquids in a given system. It converts the mechanical force exerted by the pressure into a readable display, allowing operators to monitor conditions accurately. Pressure gauges come in various types, including analog, digital, and differential gauges, each suited to specific applications.

Analog pressure gauges employ a dial and needle mechanism, providing a visual indication of pressure. These gauges are favored for their simplicity and reliability, especially in environments where electronic devices may fail due to harsh conditions. Conversely, digital pressure gauges utilize electronic sensors and displays, offering enhanced accuracy, ease of readout, and advanced features such as data logging and remote monitoring.

Types of Pressure Gauges

1. Bourdon Tube Gauges These are the most common type of pressure gauge, utilizing a curved tube that straightens as pressure increases. They are suitable for a wide range of applications, from HVAC systems to food processing.

2. Diaphragm Gauges Ideal for measuring low pressures and vacuum, diaphragm gauges use a flexible diaphragm that deflects under pressure. Their design allows them to handle viscous or corrosive fluids, making them essential in chemical processing.

3. Digital Pressure Gauges As technology advances, digital gauges have gained popularity for their high accuracy and functionality. They can include features such as backlit displays, programmable settings, and the ability to connect to other devices for comprehensive monitoring.

4. Differential Gauges These gauges measure the difference in pressure between two points, making them invaluable in applications such as filtration systems and pressure drop monitoring.

Applications of Pressure Gauges

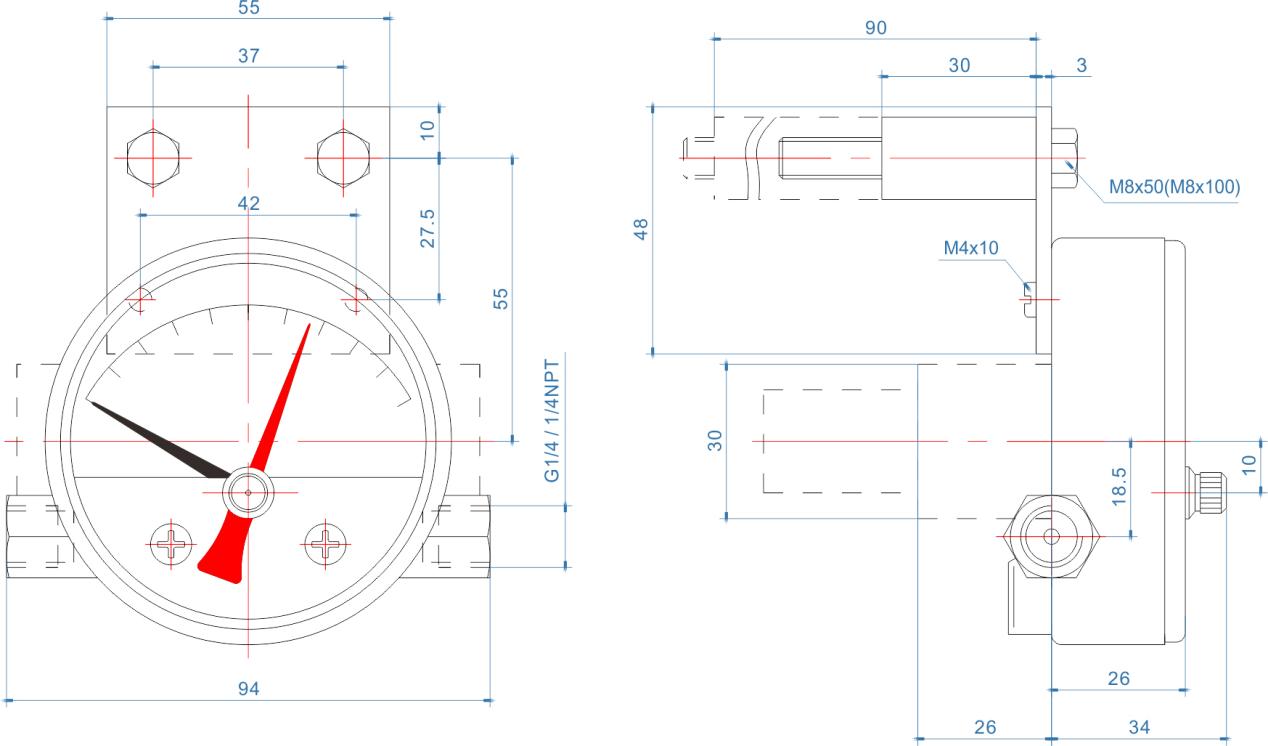

best precision instruments pressure gauges

Pressure gauges are indispensable across numerous industries. In the petroleum and natural gas sector, they monitor pipeline pressures to ensure safety and efficiency. In the food and beverage industry, pressure gauges help control processes such as brewing or carbonation, ensuring product consistency and quality.

Moreover, in manufacturing, pressure gauges are vital in hydraulic systems to maintain optimal performance and prevent equipment failure. In the medical field, these instruments are critical in devices like anesthetic machines, ensuring accurate dosing and patient safety.

Selecting the Best Pressure Gauges

Choosing the right pressure gauge involves several considerations

1. Accuracy and Precision Look for gauges that provide high fidelity in readings; digital gauges often offer superior accuracy compared to analog counterparts.

2. Range Select a gauge with a suitable pressure range for your application. An undersized gauge may fail or produce inaccurate readings, while an oversized one may not provide the data you need.

3. Material Compatibility Consider the media being measured. Ensure the gauge's materials are compatible with the fluid or gas to prevent corrosion and ensure longevity.

4. Environmental Conditions Analyze the operating environment. Some gauges are designed to withstand extreme temperatures, humidity, and vibrations. Select a gauge built for the specific conditions it will face.

5. Maintenance Choose gauges that are easy to calibrate and maintain. Digital gauges often come with self-diagnostic features, providing alerts for maintenance needs.

Conclusion

Precision instruments play a pivotal role in ensuring the safety, efficiency, and quality of processes across various industries. Pressure gauges, as fundamental elements of these systems, require thoughtful selection and maintenance. By understanding the different types, applications, and best practices, operators can ensure they are equipped with the best instruments to meet their specific needs, ultimately leading to enhanced performance and reliability in their operations. In a world where precision is paramount, investing in quality pressure gauges is a decision that pays dividends in performance and safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025