Dec . 15, 2024 11:37 Back to list

best wika differential pressure gauge

Understanding Differential Pressure Gauges A Comprehensive Guide

Differential pressure gauges are essential instruments in various industrial applications, as they measure the difference in pressure between two points in a system. This measurement is crucial in processes such as fluid flow, filtration, and HVAC systems, where maintaining the right pressure differential ensures optimal performance and efficiency. In this article, we will explore how differential pressure gauges work, their applications, and why they are integral to modern industrial operations.

How Differential Pressure Gauges Work

At its core, a differential pressure gauge consists of two pressure sensing points or ports connected to the environment or a specific process. When fluid flows through a system, these pressure points experience different pressures due to changes in elevation, flow resistance, or obstructions. The differential pressure gauge measures the difference between these two pressures, providing a clear indication of how the system is performing.

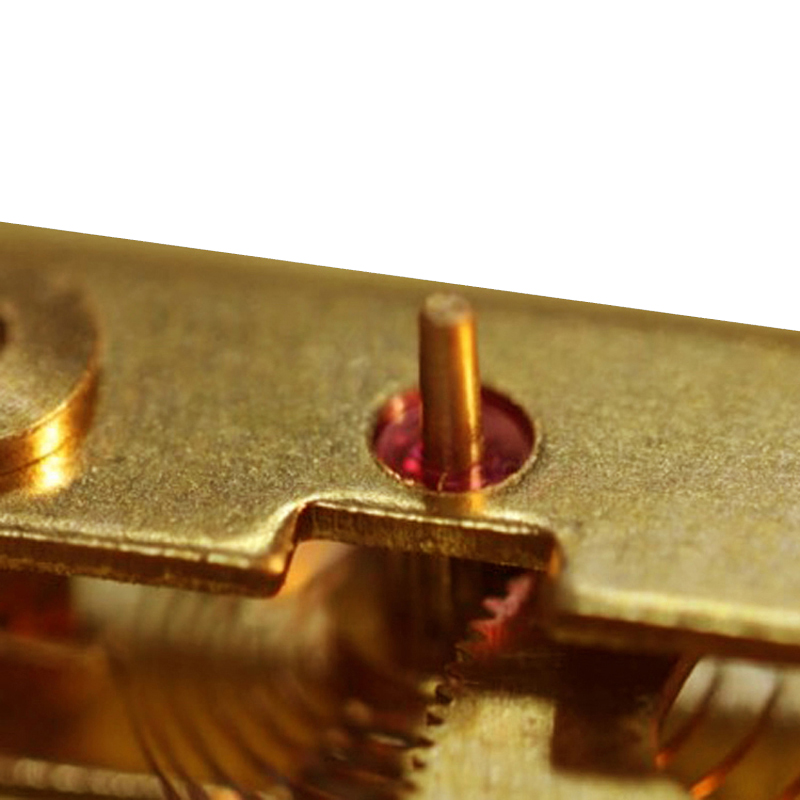

Most differential pressure gauges operate on the principle of mechanical movement. They often use a diaphragm, Bourdon tube, or a similar mechanism that responds to pressure changes. As pressure differentials occur, the diaphragm flexes or the Bourdon tube twists, which is then converted into a readable measurement on a scale. Some modern gauges utilize electronic sensors and digital displays to enhance accuracy and provide real-time data.

Applications of Differential Pressure Gauges

1. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, differential pressure gauges are critical for monitoring air filter performance. A rising differential pressure across a filter indicates clogging, suggesting it’s time for maintenance or replacement. This ensures that the HVAC systems operate efficiently, preventing energy wastage.

2. Process Control In chemical processing and manufacturing, maintaining specific pressure differentials is crucial for ensuring safe and effective operations. Differential pressure gauges help operators monitor systems that require precise pressure maintenance, such as reactors or separation vessels, enhancing both safety and efficiency.

best wika differential pressure gauge

3. Flow Measurement Differential pressure gauges can also be used in conjunction with flow meters to calculate the flow rate of liquids and gases. By measuring the pressure drop across a flow restriction (like an orifice plate), these gauges provide essential data for flow management in pipelines.

4. Filtration Monitoring The filtration process in many industries relies on maintaining optimal pressure differentials. A differential pressure gauge can alert operators to changes in filter performance, allowing for timely interventions that prevent system damage or product contamination.

5. Water Treatment Plants Differential pressure gauges are widely used in water treatment systems to monitor filtration and backwashing processes. They provide insights into filter conditions and help to ensure consistent water quality.

Importance of Choosing the Right Gauge

When selecting a differential pressure gauge, several factors should be considered. These include the range of pressures to be measured, the medium being monitored (gas, liquid, or slurry), and the environmental conditions (temperature, humidity, and potential corrosiveness). Additionally, accuracy and response time are critical, especially in processes where slight deviations from set pressures can lead to significant operational disruptions.

Conclusion

Differential pressure gauges are indispensable tools in a variety of industries, providing vital information that helps maintain system efficiency, safety, and product quality. As technology advances, more sophisticated gauges with enhanced features are becoming available, allowing for more precise measurements and better integration into automated systems. Understanding how these gauges work and their various applications can empower operators and engineers to ensure optimal performance across processes, highlighting the essential role that differential pressure gauges play in modern industrial operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025