Nov . 14, 2024 14:29 Back to list

buy budenberg diaphragm seal pressure gauge

Understanding Budenberg Diaphragm Seal Pressure Gauges A Comprehensive Guide

Pressure gauges are essential instruments used in various industrial applications to measure the pressure of gases and liquids. Among the diverse options available, Budenberg diaphragm seal pressure gauges have gained significant recognition for their reliability and accuracy, particularly in sensitive and challenging environments. This article aims to explore the features, benefits, and applications of Budenberg diaphragm seal pressure gauges, shedding light on why they are a favored choice among professionals.

What is a Diaphragm Seal Pressure Gauge?

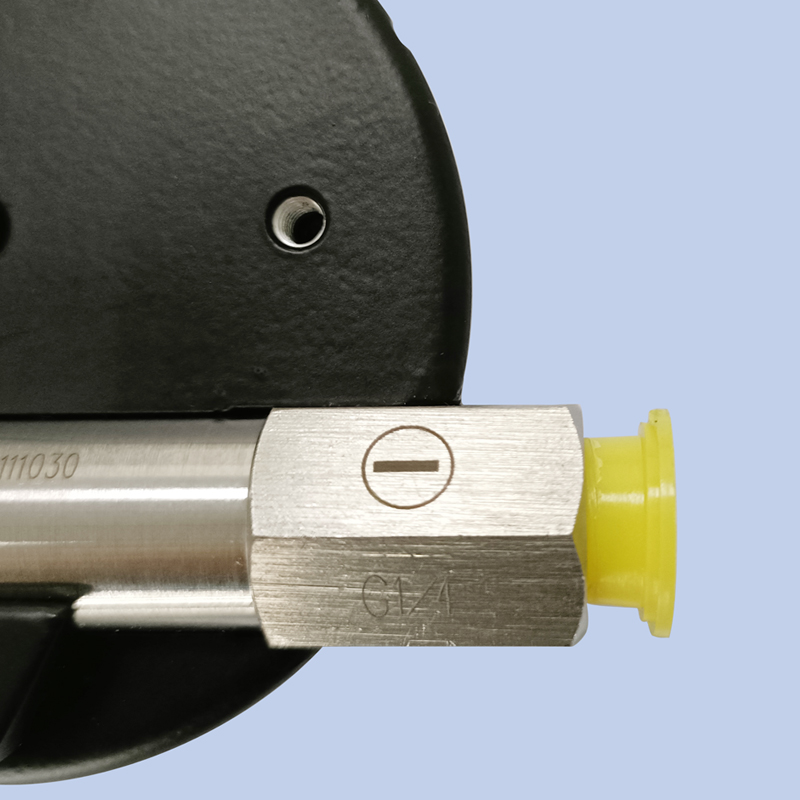

A diaphragm seal pressure gauge is a specific type of pressure gauge that utilizes a flexible diaphragm to isolate the measuring element from the process fluid. This design is particularly useful in scenarios where the fluid is corrosive, viscous, or contains solids that could damage the gauge. The diaphragm converts the pressure exerted by the fluid into a mechanical movement, which is then translated into a readable pressure measurement.

The Budenberg Advantage

Budenberg is a renowned brand in the field of pressure measurement technology. Their diaphragm seal pressure gauges stand out due to several key advantages

1. Corrosion Resistance Budenberg gauges often feature materials like stainless steel and other corrosion-resistant alloys, ensuring longevity even in harsh environments. This is particularly beneficial in industries such as chemical processing, oil and gas, and water treatment, where exposure to corrosive substances is common.

2. Customizability Budenberg offers a range of customization options for their diaphragm seal pressure gauges. Users can choose from different materials, diaphragm sizes, and connection types to meet specific operational requirements, making these gauges adaptable to various applications.

3. Accuracy and Precision The design of Budenberg diaphragm seal gauges includes high-quality components that ensure accurate pressure readings. This precision is crucial for processes that require strict adherence to pressure specifications.

4. Easy Maintenance The construction of Budenberg gauges allows for straightforward maintenance and calibration procedures. This means reduced downtime and improved reliability over the gauge's lifespan.

buy budenberg diaphragm seal pressure gauge

5. Wide Range of Applications These gauges can measure pressure in liquid and gas applications, including both low and high-pressure environments. Whether it’s monitoring pressure in a hydraulic system or tracking the pressure of gases in a chemical reactor, Budenberg delivers robust solutions.

Applications of Budenberg Diaphragm Seal Pressure Gauges

Budenberg diaphragm seal pressure gauges are employed across numerous industries, thanks to their versatility. Here are some common applications

- Chemical Processing In facilities where chemicals are stored and processed, monitoring the pressure of various reactants is vital for safety and efficiency. The corrosion-resistant properties of Budenberg gauges make them ideal for this application.

- Oil and Gas In the exploration and extraction of hydrocarbons, pressure measurement plays a critical role. Budenberg gauges are used in wells and pipelines to ensure system integrity and prevent leaks.

- Food and Beverage Maintaining the quality and safety of food products often requires monitoring pressure in sterilization processes and other critical applications, where Budenberg pressure gauges prove beneficial.

- Pharmaceuticals The pharmaceutical industry demands the highest levels of accuracy and reliability in process control. Budenberg diaphragm seal gauges help ensure that manufacturing processes adhere to strict regulatory standards.

- Water and Wastewater Treatment Pressure measurement is crucial in water infrastructure. Budenberg gauges are used to monitor pressure in filtration, pumping, and treatment systems effectively.

Conclusion

Budenberg diaphragm seal pressure gauges represent a blend of innovation, reliability, and precision. Their advanced design makes them suitable for a wide range of applications across numerous industries, particularly where harsh conditions are common. The ability to customize these gauges ensures that they can be tailored to meet specific needs, providing users with confidence in their measurements. If you're looking to invest in a pressure measurement solution, consider the Budenberg diaphragm seal pressure gauge as a reliable option that brings together quality and performance in one robust package.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025