Dec . 03, 2024 17:19 Back to list

Purchase Capacitive Diaphragm Pressure Gauges for Accurate Measurement Solutions

Understanding the Buy Capacitance Diaphragm Pressure Gauge

Pressure measurement is a vital aspect of many industries, from manufacturing to healthcare. A key instrument for this purpose is the capacitance diaphragm pressure gauge. As technology advances, the demand for precise pressure measurement tools has grown, leading to the increased usage of these gauges. This article explores the features, benefits, and considerations surrounding the purchase of a capacitance diaphragm pressure gauge.

What is a Capacitance Diaphragm Pressure Gauge?

A capacitance diaphragm pressure gauge operates based on the principle of capacitance changes caused by diaphragm deflection under pressure. When pressure is applied to the diaphragm, it distorts, altering the capacitance of an internal capacitor. This change is then transformed into an electrical signal proportional to the pressure exerted. Such gauges offer remarkable sensitivity and accuracy, making them suitable for a range of applications.

Advantages of Capacitance Diaphragm Pressure Gauges

1. High Accuracy Capacitance diaphragm gauges provide superior accuracy compared to traditional mechanical gauges. This precision is critical in industries like pharmaceuticals and aerospace, where even minute variations in pressure can lead to significant issues.

2. Wide Pressure Range These gauges can measure both low and high-pressure applications. This versatility makes them ideal for various settings, from laboratory experiments to heavy industrial processes.

3. Minimal Drift and Hysteresis Unlike mechanical gauges, capacitance devices exhibit minimal drift over time and reduced hysteresis effects. This characteristic allows for reliable long-term monitoring of pressure without frequent recalibration.

5. Non-Contact Measurement Since the measurement relies on capacitance rather than mechanical movement, there is less wear and tear on internal components, which can extend the lifespan of the gauge.

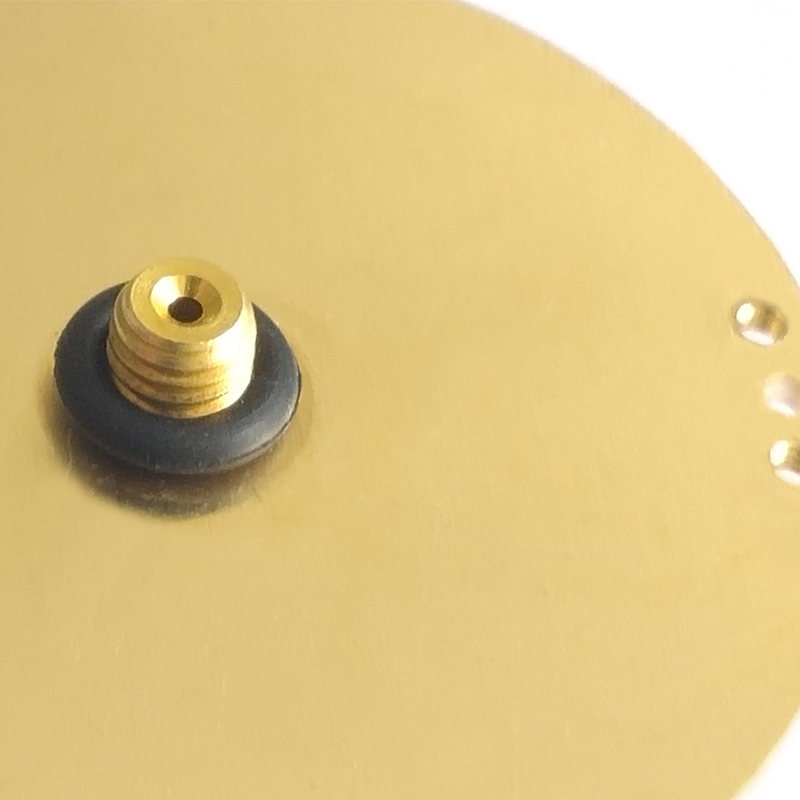

buy capacitance diaphragm pressure gauge

Key Considerations When Buying a Capacitance Diaphragm Pressure Gauge

1. Measurement Range Determine the specific pressure range needed for your application. Selecting a gauge that matches your required measurement range ensures accuracy and efficiency in pressure readings.

2. Material Compatibility The medium being measured may affect gauge materials. Ensure that the materials used in the diaphragm and housing are compatible with the substances being measured to avoid corrosion or contamination.

3. Accuracy Specifications Look for gauges with clear accuracy ratings. Understanding the specifications can help you choose a model that aligns with your operational needs.

4. Calibration Needs Although capacitance gauges typically have excellent calibration stability, it's essential to consider the calibration requirements to ensure ongoing precision in measurements.

5. Environmental Factors Assess the operating conditions, such as temperature, humidity, and potential exposure to corrosive environments. Choose a gauge designed to perform under these conditions effectively.

Conclusion

The capacitance diaphragm pressure gauge stands out as a highly effective and reliable tool for pressure measurement across various industries. With their precise readings, minimal maintenance requirements, and versatile applications, they represent a significant advancement over traditional pressure measurement technologies. When looking to purchase a capacitance diaphragm pressure gauge, it’s crucial to consider factors like measurement range, material compatibility, and environmental conditions to ensure optimal performance.

In summary, investing in a capacitance diaphragm pressure gauge can enhance the accuracy and reliability of pressure readings, ultimately contributing to a more efficient and safe operational environment. As industries continue to innovate and expand, such advanced tools will play a critical role in meeting the demands of modern technology and processes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025