Oct . 18, 2024 20:36 Back to list

buy magnetic differential pressure gauge

Understanding and Purchasing Magnetic Differential Pressure Gauges

In industrial applications, the importance of accurate pressure measurement cannot be overstated. Among the various devices available for measuring pressure, magnetic differential pressure gauges are becoming increasingly popular due to their reliability, performance precision, and adaptability in diverse settings. This article aims to delve into the functionalities of magnetic differential pressure gauges, their advantages, and considerations for purchase.

What is a Magnetic Differential Pressure Gauge?

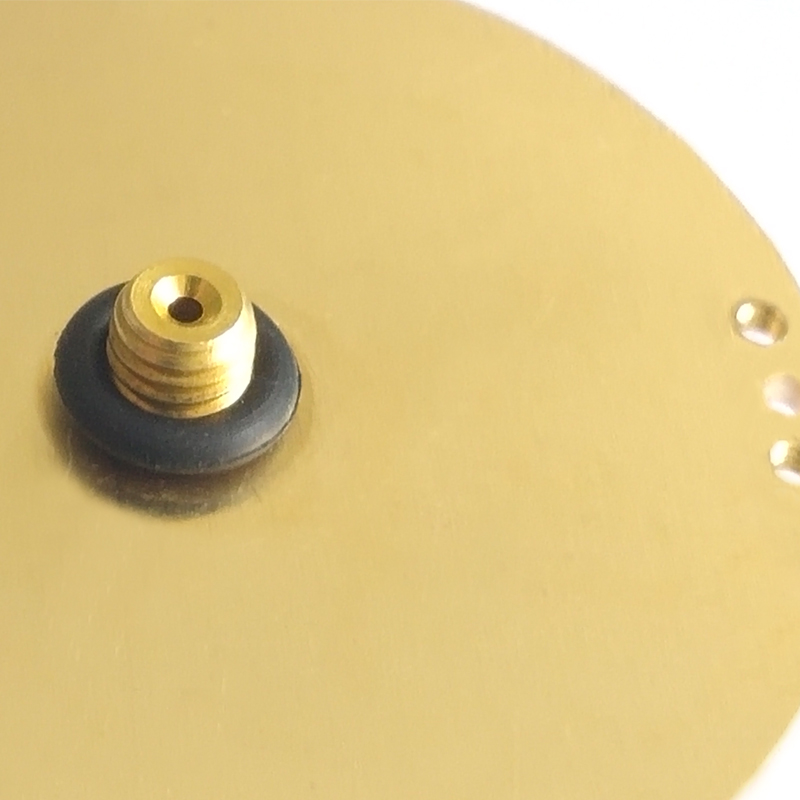

A magnetic differential pressure gauge is a device designed to measure the difference in pressure between two points in a system. It utilizes a magnetic float and a measuring tube that responds to pressure changes by moving the float, which is linked to a magnetic rod. This rod then translates the movements into a readable output on a dial or display. The gauge can measure both positive and negative pressure differentials and is commonly used in applications such as HVAC systems, filtration monitoring, and fluid transfer processes.

Advantages of Magnetic Differential Pressure Gauges

1. Durability and Reliability One of the primary advantages of magnetic differential pressure gauges is their robust design. They are resistant to harsh environmental conditions and can function accurately over a range of temperatures and pressures. This durability makes them ideal for industrial settings where equipment is subject to wear and tear.

2. No Need for External Power Unlike electronic pressure sensors that require power sources, magnetic differential pressure gauges operate mechanically. This characteristic is beneficial in remote or hazardous locations where power availability may be inconsistent or where electrical safety is paramount.

3. Accuracy and Response Time These gauges are known for their high level of accuracy and quick response time. The mechanical nature of the device minimizes the time lag often seen in electronic sensors, providing real-time readings that are crucial for maintaining optimal operational conditions.

4. Versatility Magnetic differential pressure gauges can be tailored for various applications. They can be configured for different pressure ranges and can measure gases, liquids, and slurries, making them a versatile choice for many industries, including water treatment, pharmaceuticals, and petrochemicals.

5. Maintenance Another key benefit is the low maintenance requirement. Since they have fewer moving parts, magnetic differential gauges are less prone to mechanical failures compared to other gauge types, reducing overall maintenance costs and downtime.

buy magnetic differential pressure gauge

Considerations for Purchasing Magnetic Differential Pressure Gauges

When looking to purchase a magnetic differential pressure gauge, several factors should be taken into account to ensure you select the best device for your specific needs

1. Pressure Range Assess the range of pressure differentials that will be measured in your application. Different gauges are designed for various ranges, and selecting one that is appropriate for your requirements is crucial.

2. Fluid Compatibility Ensure that the materials used in the construction of the gauge are compatible with the fluids it will come into contact with. This is particularly important in chemical processing or food industries, where material compatibility can affect safety and accuracy.

3. Installation Consider the installation requirements. Some gauges are more straightforward to install than others, and you should evaluate whether you have the necessary equipment and expertise for installation.

4. Calibration Determine how easy it is to calibrate the gauge. Regular calibration is essential to maintain accuracy, so a device that allows for simple adjustments will be more advantageous.

5. Budget Finally, evaluate your budget. While it may be tempting to go for the cheapest option, investing in a quality gauge from a reputable manufacturer can save you costs in the long run through reduced maintenance and enhanced reliability.

Conclusion

In conclusion, magnetic differential pressure gauges play a crucial role in numerous industries by providing essential measurements that help maintain optimal operational efficiency. With their durability, accuracy, and low-maintenance requirements, they stand out as a reliable solution for pressure measurement needs. When considering a purchase, take the time to assess your specific requirements and choose a gauge that aligns with the demands of your application. Investing in a high-quality magnetic differential pressure gauge will not only enhance the reliability of your operations but also contribute to overall productivity and safety in your workplace.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025