Nov . 16, 2024 16:31 Back to list

buy railway pressure gauge

Understanding and Buying Railway Pressure Gauges

In the railway industry, precision and safety are paramount. One of the critical components that ensure the proper functioning of railway systems is the pressure gauge. Among various types of pressure gauges, railway pressure gauges are specifically designed to monitor the pressure levels in steam locomotives and other related systems. This article will delve into what railway pressure gauges are, their importance, and factors to consider when buying them.

What is a Railway Pressure Gauge?

A railway pressure gauge is an instrument that measures and displays the pressure of steam or other gases within the locomotive’s boiler or other components. These gauges come in various forms, including analog and digital displays. The primary purpose of a railway pressure gauge is to help operators manage the pressure within acceptable limits, ensuring the locomotive operates under safe conditions.

Importance of Railway Pressure Gauges

1. Safety The primary function of a railway pressure gauge is to enhance safety. Monitoring the steam pressure allows operators to avoid dangerous pressure levels, which could lead to catastrophic failures or explosions.

2. Performance Monitoring Regular readings from pressure gauges can help in diagnosing potential issues within the locomotive system. Any fluctuations from the normal pressure range may indicate problems that need immediate attention, enabling preventative maintenance and extending the life of the equipment.

3. Efficiency Accurate pressure readings allow for improved fuel efficiency. By maintaining optimal pressure levels, locomotives can operate more effectively, leading to cost savings in fuel and reduced operational downtime.

4. Compliance Railways are often subject to strict regulations regarding safety and operational standards. Having a reliable pressure gauge helps ensure compliance with these regulations, avoiding potential fines and enhancing safety protocols.

Choosing the Right Railway Pressure Gauge

buy railway pressure gauge

When it comes to buying a railway pressure gauge, several factors must be considered

1. Type of Gauge Determine whether you need an analog or digital gauge. Analog gauges are traditional and straightforward but may be less precise than their digital counterparts. Digital gauges, on the other hand, often offer advanced features such as data logging and wireless connectivity.

2. Pressure Range Assess the required pressure range for your specific application. Different locomotives operate under various pressure conditions, so it’s crucial to choose a gauge that can accurately measure your system's requirements.

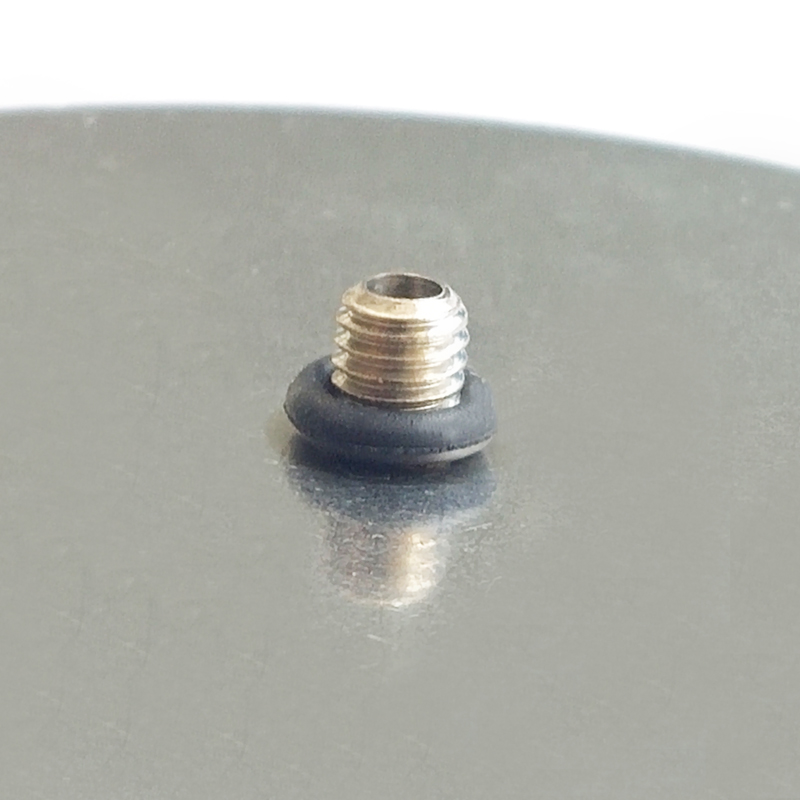

3. Material and Durability Railways operate in challenging environments. Choose a pressure gauge constructed from robust materials that can withstand vibrations, temperature fluctuations, and potential exposure to moisture and dirt. Stainless steel or brass are common materials that offer durability in railway applications.

4. Calibration and Accuracy Make sure the gauge is calibrated according to industry standards. An accurate gauge is essential for safe and efficient operations. Check if the manufacturer provides calibration certificates and support.

5. Installation and Maintenance Consider how easy it is to install the gauge and how much maintenance it will require over time. Some gauges come with user-friendly installation kits and require minimal upkeep.

6. Cost Finally, factor in your budget. While it is important to find a gauge that meets your requirements, you also want one that fits your budget. However, be wary of compromising on quality for the sake of cost; a faulty pressure gauge can lead to safety issues and expensive repairs down the line.

Conclusion

In conclusion, railway pressure gauges play a crucial role in the safety, performance, and compliance of railway operations. Selecting the right one involves understanding their function, evaluating specific requirements, and ensuring reliable performance under various conditions. By taking the time to choose quality railway pressure gauges, operators can enhance efficiency, improve safety, and maintain the integrity of their rail systems. As always, it is wise to consult with industry professionals or reputable suppliers to find a gauge tailored to your specific needs.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025