Sep . 06, 2024 16:58 Back to list

Capillary Diaphragm Seal Pressure Gauge Manufacturer

Understanding Capillary Diaphragm Seal Pressure Gauges

In various industrial applications, accurate pressure measurement is critical for ensuring safety, reliability, and efficiency. Among the advanced technologies employed for this purpose is the capillary diaphragm seal pressure gauge. This innovative instrument is specially designed to measure pressure in environments where traditional gauges might fail, particularly in high-temperature or corrosive settings.

What is a Capillary Diaphragm Seal Pressure Gauge?

A capillary diaphragm seal pressure gauge consists of a pressure-sensitive mechanism, typically a diaphragm, connected via a capillary tube to the pressure gauge itself. The diaphragm, which is the core of the gauge, separates the process fluid from the sensing element. This ensures that the gauge can measure pressure without being directly exposed to harsh conditions, such as aggressive chemicals or extreme temperatures.

The capillary tube provides flexibility in positioning the gauge away from the process fluid. This is particularly beneficial in situations where space is limited or where the gauge needs to be located in a more accessible or less hazardous area. Additionally, the capillary tube can help in preventing the gauge from freezing, which can occur in low-temperature applications.

Advantages of Capillary Diaphragm Seal Pressure Gauges

One of the primary advantages of using a capillary diaphragm seal pressure gauge is its ability to handle a wide range of process conditions. The diaphragm material can be selected based on the chemical compatibility required for specific fluids, ensuring longevity and reliability.

capillary diaphragm seal pressure gauge factory

Another significant benefit is the protection it offers against pulsations and shocks. Industries such as oil and gas, chemical processing, and food production often deal with fluctuating pressures. The design of these gauges effectively dampens such variations, providing accurate readings and protecting the internal mechanisms from damage.

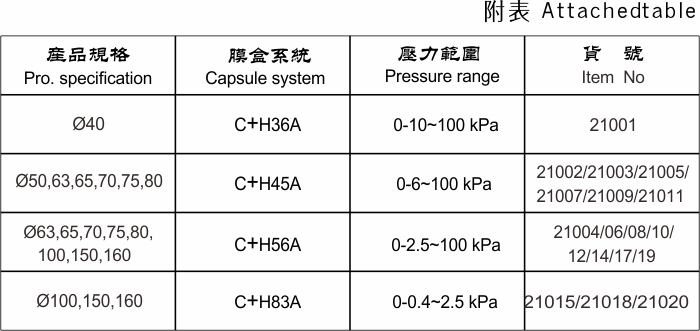

Moreover, these gauges can be customized to fit specific applications. Manufacturers often offer various diaphragm materials, capillary lengths, and fittings to meet precise customer needs. This customization ensures that industries can find the right gauge for their unique requirements, thus improving overall operational efficiency.

Applications

Capillary diaphragm seal pressure gauges are widely used across multiple sectors. In the chemical industry, for instance, they are essential for monitoring pressure in reactors and storage tanks containing hazardous substances. Similarly, in the food and beverage sector, they are utilized to ensure that pressure levels in processing equipment remain within safe parameters, thereby maintaining product quality and safety.

Other applications include petrochemical plants, where these gauges help measure the pressure of corrosive gases and liquids, and hospitals, where they can monitor pressure in critical medical equipment without risking contamination.

Conclusion

Capillary diaphragm seal pressure gauges represent a vital tool in the arsenal of industrial measurement instruments. Their unique design and features make them invaluable for accurate pressure measurement in challenging environments. As industries continue to evolve and face new challenges, the importance of reliable and durable pressure measurement solutions, such as these gauges, cannot be overstated. Investing in high-quality capillary diaphragm seal pressure gauges from reputable factories ensures that businesses maintain operational efficiency and uphold safety standards in their respective fields.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025