Dec . 12, 2024 03:43 Back to list

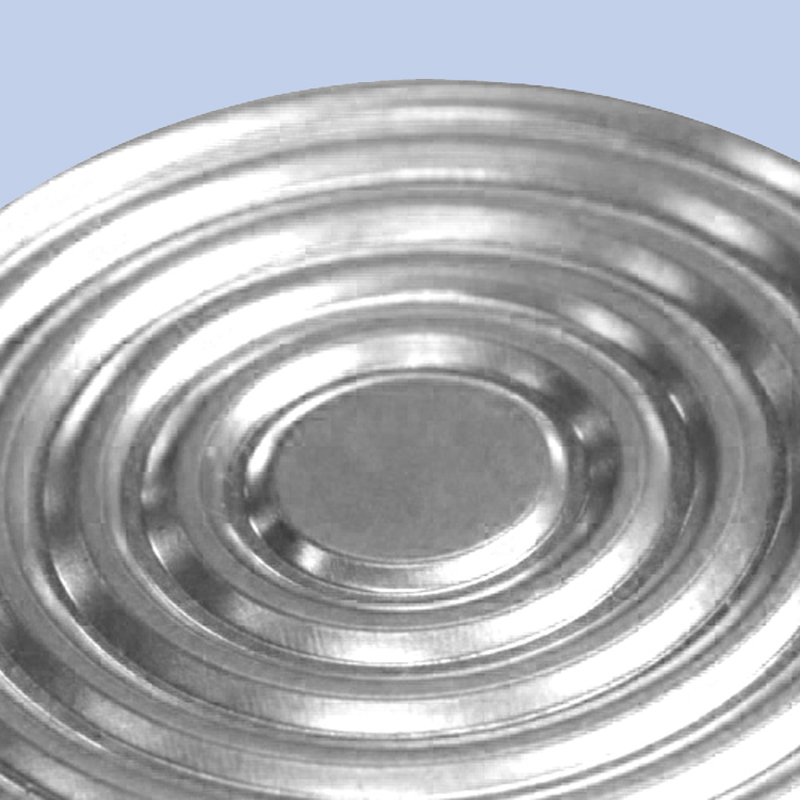

capillary type differential pressure gauge jah

Understanding Capillary Type Differential Pressure Gauges

Capillary type differential pressure gauges are essential instruments in various industrial applications. They are specifically designed to measure the pressure difference between two points in a system, which is crucial for maintaining system efficiency and safety. This article delves into the functioning, advantages, and applications of capillary type differential pressure gauges.

How They Work

Capillary type differential pressure gauges operate on a relatively straightforward principle of differential pressure measurement. The gauge consists of two diaphragms, each exposed to different pressures, connected by thin, flexible capillary tubes. These tubes allow the fluid – typically a liquid or gas – to transmit the pressure from the points being measured to the gauge.

When there is a pressure difference between the two points, it exerts a force on the diaphragms. This force causes a deflection in the diaphragm, which is then translated into a readable value on the gauge display. This design allows for highly sensitive measurements, making these gauges suitable for detecting even small pressure changes.

Advantages of Capillary Type Differential Pressure Gauges

1. Sensitivity and Accuracy One of the key advantages of capillary type differential pressure gauges is their high sensitivity. They can detect very small changes in pressure, making them ideal for applications where precision is paramount.

2. Ability to Measure Non-Viscous Fluids These gauges can measure pressures of non-viscous fluids effectively. This characteristic expands their application in various industrial processes that involve gases or low-viscosity liquids.

3. Remote Measurement The use of capillary tubes allows for remote pressure measurement, enabling operators to monitor systems from a safe distance. This capability is especially beneficial in hazardous environments or when dealing with high pressures.

4. Robust Design Capillary gauges are generally robust and can be designed to withstand harsh environmental conditions. This durability extends their lifespan and reduces maintenance costs, making them a reliable choice for long-term use in demanding applications.

capillary type differential pressure gauge jah

5. Simple Installation The straightforward installation process reduces downtime and allows for quick setup. This feature is particularly important in fast-paced industrial settings where time is of the essence.

Applications

Capillary type differential pressure gauges are utilized across various industries, including

- Oil and Gas They are often used to monitor the pressure differences in pipelines, ensuring safe and efficient transportation of crude oil and natural gas.

- Pharmaceuticals In pharmaceutical manufacturing, precise pressure control is critical. These gauges help in maintaining the required pressure conditions during various production processes.

- HVAC Systems In heating, ventilation, and air conditioning systems, capillary gauges are employed to measure air and fluid pressure differences, ensuring proper system performance and comfort.

- Food and Beverage In this industry, maintaining specific pressure levels is vital for product safety and quality. Capillary gauges aid in monitoring and controlling these pressures.

Conclusion

Capillary type differential pressure gauges are indispensable tools in modern industry. Their ability to provide accurate, sensitive measurements of pressure differences makes them essential for a wide range of applications. With advantages like remote measurement capabilities and robust design, these gauges enhance operational efficiency and safety. As industries continue to innovate, the importance of such precise measurement tools will only grow, highlighting the enduring relevance of capillary type differential pressure gauges in today's technology-driven world.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025