Nov . 08, 2024 16:33 Back to list

capsuhelic differential pressure gauge factory

Understanding Capsule Differential Pressure Gauges A Comprehensive Overview

Capsule differential pressure gauges are specialized instruments designed to measure the pressure difference between two points in a system. These devices are widely used across various industries, including oil and gas, pharmaceuticals, water treatment, and food processing. This article explores the functioning, applications, and advantages of capsule differential pressure gauges, shedding light on their significance and reliability in modern measurement technology.

Construction and Operating Principle

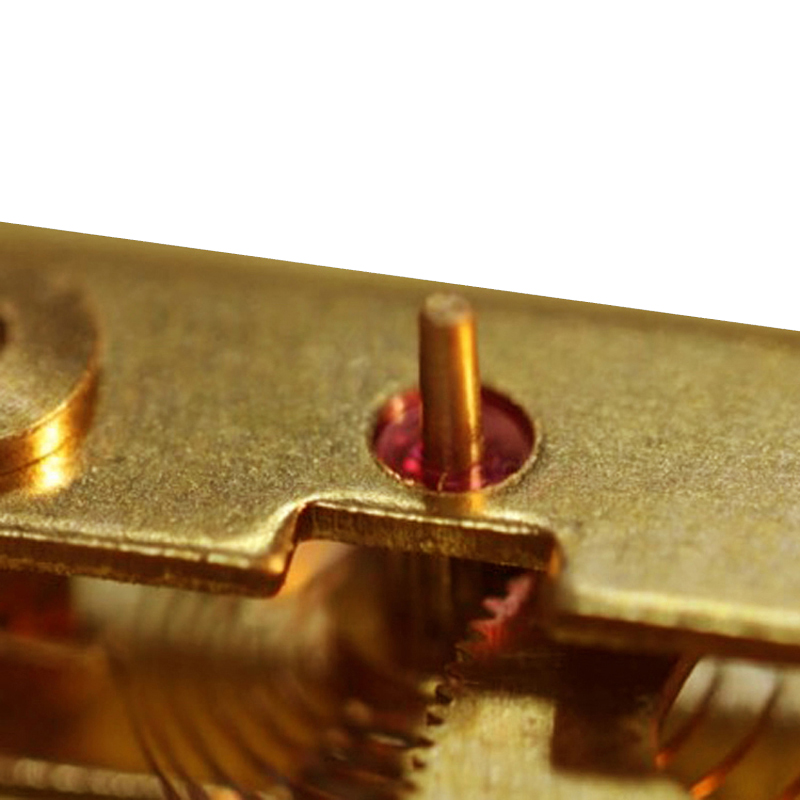

The fundamental design of a capsule differential pressure gauge comprises two flexible metal capsules that are joined along their circumferences. These capsules are sensitive to pressure differences; as the pressure varies between the two sides, they deform accordingly. This deformation is mechanical and translates into a readable dial or electronic signal.

When there is a pressure difference, one capsule will compress while the other expands. This differential movement is connected to a mechanical system that converts the motion into a rotational movement of the gauge needle, providing a clear visual representation of the pressure difference. The scale on the dial is calibrated to reflect the pressure readings accurately, making it easy for operators to interpret the results.

Applications in Various Industries

Capsule differential pressure gauges are essential tools in multiple applications

1. Oil and Gas Industry These gauges are used to monitor pressure levels in pipelines and tanks, ensuring the safe transport of crude oil and natural gas. They help prevent over-pressurization, which can lead to catastrophic failures.

2. Pharmaceuticals In cleanroom environments and during the manufacturing of drugs, ensuring the correct pressure differentiation is critical for maintaining sterile conditions and product integrity. Capsule gauges help monitor filter pressures and validate the performance of air filtration systems.

4. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, capsule differential pressure gauges help regulate airflow, ensuring efficiency and comfort in residential and commercial spaces.

capsuhelic differential pressure gauge factory

5. Food Processing Maintaining the right pressure in food processing equipment is vital for safety and compliance with health regulations. Capsule gauges provide accurate pressure readings, aiding in the quality control of the manufacturing process.

Advantages of Capsule Differential Pressure Gauges

Capsule differential pressure gauges offer several advantages that make them a preferred choice in many applications

- High Sensitivity These gauges can measure very small pressure differences, making them ideal for sensitive applications where precision is paramount.

- Robust Design The mechanical design of capsule gauges makes them resistant to vibration and shocks, ensuring reliability even in harsh environments.

- Ease of Installation Capsule gauges are typically easy to install and require minimal maintenance, which can lead to reduced downtime in industrial applications.

- Versatility With a range of pressure ratings and sizes available, capsule differential pressure gauges can be customized to fit specific application needs.

- Cost-Effectiveness Compared to electronic counterparts, mechanical capsule gauges are often more affordable and can offer a prolonged lifespan with proper care.

Conclusion

Capsule differential pressure gauges are invaluable instruments in many industries, providing accurate and reliable pressure measurements that are essential for safety and quality assurance. Their robust design, sensitivity, and versatility make them an excellent choice for monitoring pressure differences in various applications. As technology continues to evolve, these gauges will likely remain a cornerstone of industrial measurement equipment, contributing to efficiency and safety across diverse sectors. Whether in a laboratory or an oil field, the importance of accurate pressure measurement cannot be overstated, and capsule differential pressure gauges stand out as a reliable solution.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025