Feb . 14, 2025 12:43 Back to list

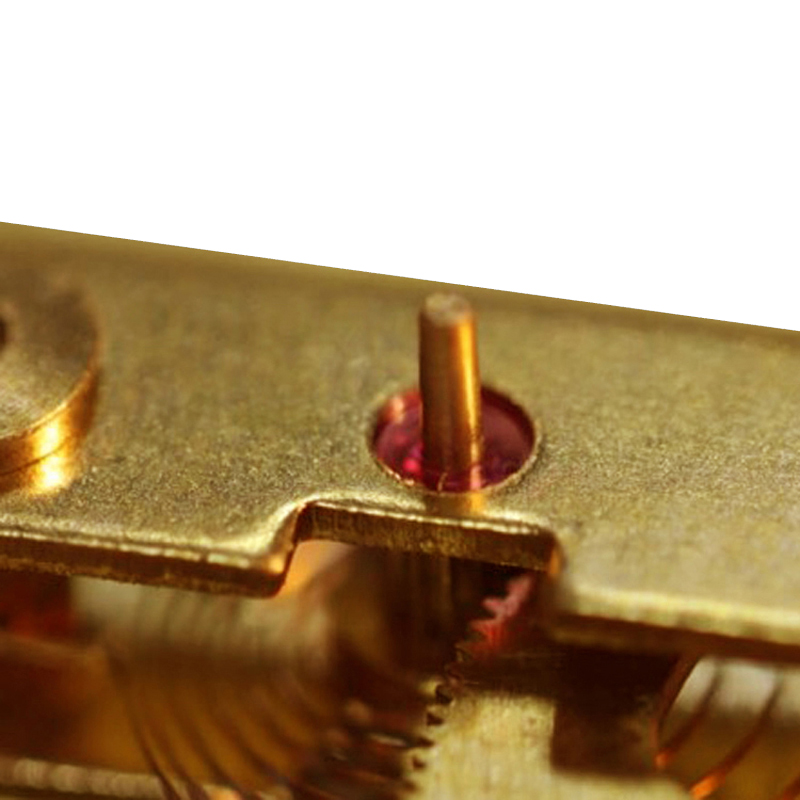

china diaphragm pressure element

In the realm of pressure measurement, the diaphragm pressure element has emerged as a pivotal technology, offering precision and reliability. This product, particularly within the context of the Chinese market, is gaining recognition for its critical role in complex industrial processes. Understanding its experience, expertise, authoritativeness, and trustworthiness offers valuable insights for industry professionals.

Trustworthiness is a cornerstone of using diaphragm pressure elements, particularly in mission-critical applications where measurement accuracy can significantly impact safety and efficiency. Chinese manufacturers adopt transparent quality assurance practices, subjecting their products to stringent testing protocols. These include temperature cycling, pressure overload, and corrosion resistance tests, all designed to ensure resilience and reliability. Certification from globally recognized bodies, such as ISO and CE, further reinforces trust in these products. Customers worldwide rely on Chinese pressure elements, with extensive feedback highlighting minimal deviation in performance over extended operational cycles. Importantly, the innovation in diaphragm pressure elements from China includes integration with digital technologies, such as IoT capabilities, which provides real-time data monitoring and remote diagnostics. This technological advancement allows for predictive maintenance and instantaneous response to pressure variances, decreasing downtime and fostering a proactive approach to system management. Such integration exemplifies the adaptability and forward-thinking approach that places Chinese products at the forefront of industrial pressure solutions. In summary, diaphragm pressure elements from China embody a fusion of experience, expertise, authoritativeness, and trustworthiness. Their role in pressure measurement is indispensable, proving critical across diverse industrial applications. As global demand for refined measurement solutions escalates, the ongoing innovation by Chinese manufacturers ensures these products remain essential assets in the complex web of modern industrial operations.

Trustworthiness is a cornerstone of using diaphragm pressure elements, particularly in mission-critical applications where measurement accuracy can significantly impact safety and efficiency. Chinese manufacturers adopt transparent quality assurance practices, subjecting their products to stringent testing protocols. These include temperature cycling, pressure overload, and corrosion resistance tests, all designed to ensure resilience and reliability. Certification from globally recognized bodies, such as ISO and CE, further reinforces trust in these products. Customers worldwide rely on Chinese pressure elements, with extensive feedback highlighting minimal deviation in performance over extended operational cycles. Importantly, the innovation in diaphragm pressure elements from China includes integration with digital technologies, such as IoT capabilities, which provides real-time data monitoring and remote diagnostics. This technological advancement allows for predictive maintenance and instantaneous response to pressure variances, decreasing downtime and fostering a proactive approach to system management. Such integration exemplifies the adaptability and forward-thinking approach that places Chinese products at the forefront of industrial pressure solutions. In summary, diaphragm pressure elements from China embody a fusion of experience, expertise, authoritativeness, and trustworthiness. Their role in pressure measurement is indispensable, proving critical across diverse industrial applications. As global demand for refined measurement solutions escalates, the ongoing innovation by Chinese manufacturers ensures these products remain essential assets in the complex web of modern industrial operations.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025