Sep . 21, 2024 12:44 Back to list

china diaphragm pressure gauge

Understanding China Diaphragm Pressure Gauges A Comprehensive Overview

In various industrial applications, accurate pressure measurement is crucial for ensuring safety and efficiency. Among the different types of pressure measurement tools available in the market, diaphragm pressure gauges have gained significant attention due to their reliability and precision. This article explores diaphragm pressure gauges, with a particular focus on those produced in China, discussing their working principles, applications, and advantages.

What is a Diaphragm Pressure Gauge?

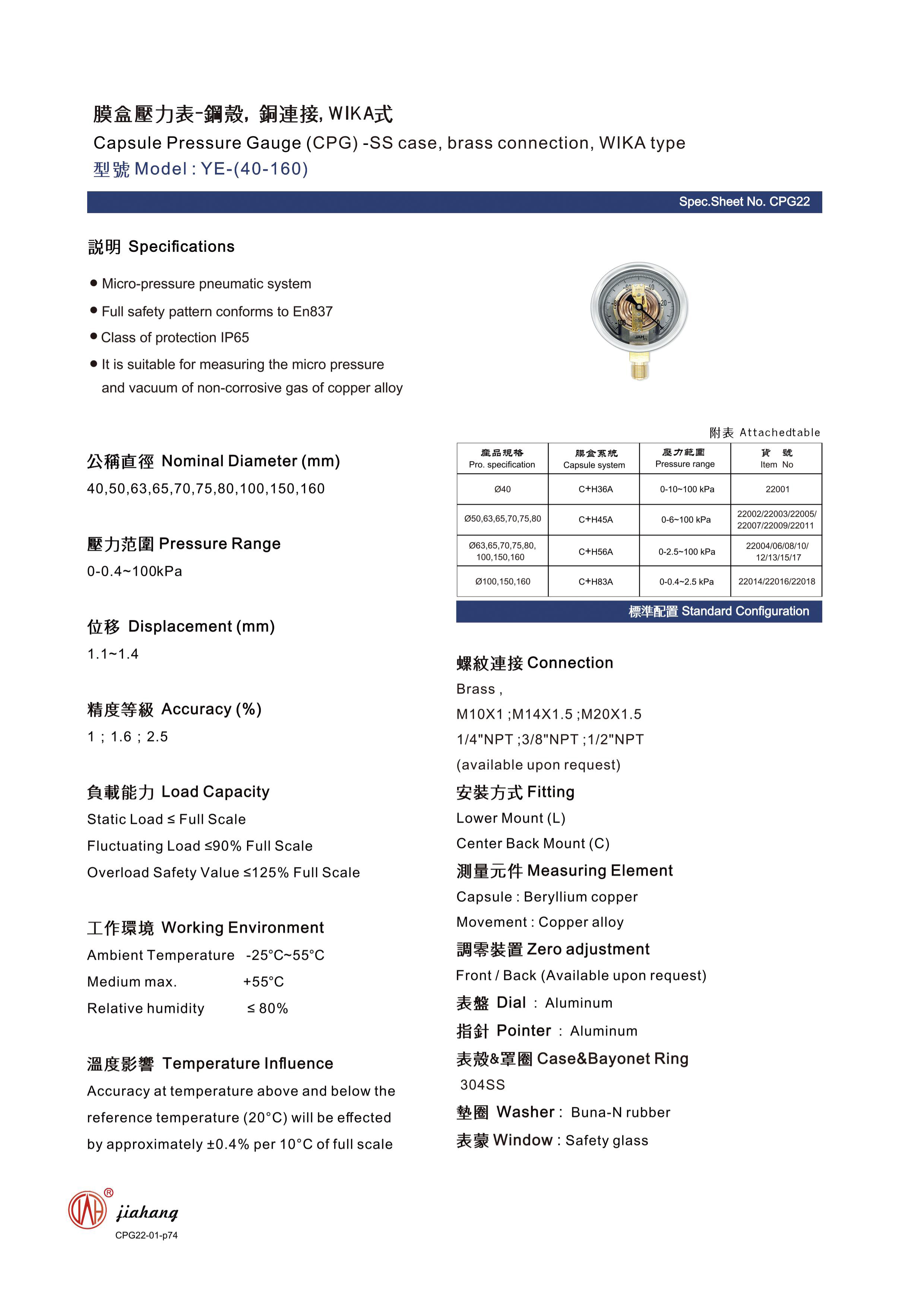

A diaphragm pressure gauge is a device used to measure the pressure of gases and liquids in a variety of settings. It operates based on a flexible diaphragm that deforms in response to pressure changes. When the pressure increases, the diaphragm bends, and this movement is translated into a readable measurement on a dial or digital display. The mechanical design typically involves a circular diaphragm sealed at the edges, allowing for differential pressure measurement in certain models.

Key Features of Diaphragm Pressure Gauges

One of the critical features of diaphragm pressure gauges is their ability to withstand corrosive and challenging environments. Many gauges produced in China are designed with materials like stainless steel or special alloys to resist corrosion, making them suitable for use in the chemical industry, pharmaceuticals, and food processing. Additionally, many manufacturers offer custom solutions to cater to specific industrial needs, including varying pressure ranges, sizes, and mounting options.

Another notable aspect is their sensitivity. Diaphragm gauges can measure very low pressures accurately, which makes them ideal for applications such as HVAC systems and vacuum measurements. Moreover, they often have a high resistance to shock and vibrations, enhancing durability in dynamic settings.

Applications of Diaphragm Pressure Gauges

china diaphragm pressure gauge

Diaphragm pressure gauges are used across numerous industries. In the oil and gas sector, they are crucial for monitoring pipeline pressures, ensuring that operations remain within safe limits. In manufacturing, these gauges help maintain optimal pressure levels in various processes, thereby controlling production quality.

In the water treatment industry, diaphragm gauges play an essential role in maintaining proper pressure in filtration systems and reactors. The pharmaceutical sector also benefits from these gauges, where precise pressure measurement is crucial for regulatory compliance and product quality.

The Advantages of Choosing Chinese Manufacturers

China is home to numerous manufacturers specializing in diaphragm pressure gauges. The advantage of choosing products from these manufacturers lies in the balance of cost-effectiveness and quality. Many Chinese companies prioritize modern manufacturing techniques and quality control measures, which ensure that their products meet international standards.

Furthermore, as global supply chains continue to evolve, many Chinese manufacturers offer flexible lead times, which is essential for businesses requiring swift production cycles. They often have the capability to provide bulk orders without compromising on quality, making them an attractive option for industries with large-scale needs.

Conclusion

Diaphragm pressure gauges are indispensable tools in various industrial applications, primarily due to their accuracy and robust design. With the ongoing advancements in manufacturing technology, Chinese manufacturers have established themselves as reputable producers of these essential instruments, offering products that meet diverse industry requirements. As industries continue to grow and evolve, the reliance on precise pressure measurement tools like diaphragm pressure gauges will only increase, reaffirming their importance in maintaining both safety and efficiency in operations.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025