Jul . 23, 2024 14:29 Back to list

Choosing the Right Differential Pressure Gauge for Your Needs and Manufacturer Considerations

Understanding Differential Pressure Gauges Importance and Applications

Differential pressure gauges are essential instruments used across a variety of industries to measure the difference in pressure between two points within a system. These gauges play a crucial role in maintaining safety, efficiency, and reliability in equipment operation. From gas and liquid flow measurement to filter monitoring and leak detection, the functionalities of differential pressure gauges are vast and integral to many processes.

What is a Differential Pressure Gauge?

A differential pressure gauge is designed to measure the difference in pressure between two separate points. It typically consists of two pressure inlets one connected to the higher pressure side and the other to the lower pressure side. The gauge then displays this pressure difference, usually in units such as psi (pounds per square inch), bar, or Pascal. Understanding this pressure differential is vital for ensuring optimal performance of various systems, whether they are HVAC systems, industrial processes, or even laboratory setups.

How Differential Pressure Gauges Work

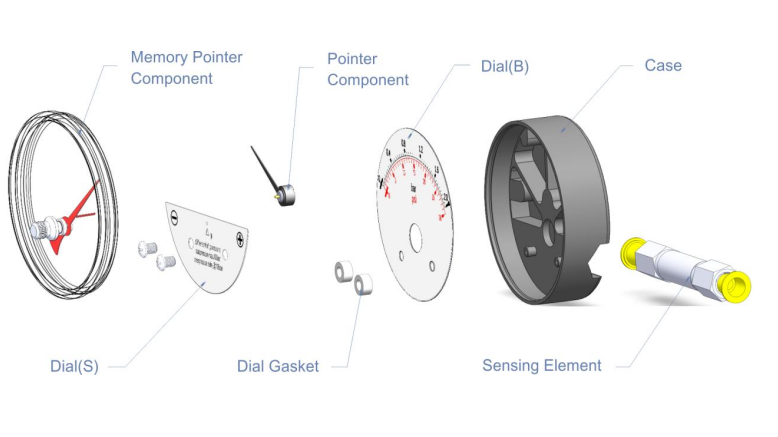

The operating principle behind differential pressure gauges can be based on different technologies, including mechanical and electronic methods. Mechanical gauges often use a diaphragm or a Bourdon tube that deforms under pressure changes, translating this movement into a readable gauge indication. On the other hand, electronic differential pressure gauges utilize sensors, such as piezoelectric elements or capacitive sensors, which offer higher accuracy and the ability to transmit data to other systems for further analysis.

Applications in Various Industries

1. HVAC Systems In heating, ventilation, and air conditioning (HVAC) systems, differential pressure gauges are critical for measuring the pressure drop across filters and ensuring they are functioning correctly. A significant pressure difference may indicate that a filter is clogged and needs replacement, preserving system efficiency and air quality.

differential pressure gauge p& manufacturer

2. Process Industries In chemical and petrochemical industries, differential pressure gauges are employed to monitor pressure in separation equipment, like distillation columns and absorbers. This helps in optimizing chemical reactions and maintaining safety protocols.

3. Water Treatment In water treatment facilities, these gauges monitor the pressure across membranes in reverse osmosis systems or filtration units. By tracking pressure differentials, operators can ensure the systems are working effectively and detect issues like membrane fouling early on.

4. Pharmaceutical and Food Industries Strict regulatory standards in these sectors demand precise control and monitoring. Differential pressure gauges help maintain aseptic conditions within processing equipment, preventing contamination by ensuring the appropriate pressure differentials are kept.

Prominent Manufacturers of Differential Pressure Gauges

The market for differential pressure gauges features a variety of prominent manufacturers, each bringing its own innovations and reliability to the table. Companies such as WIKA, Ashcroft, and Omega Engineering have established themselves as leaders. They provide a range of products that include both analog and digital gauges, catering to different accuracy levels and environmental conditions. Advanced features—such as wireless transmission, integrated alarms, and real-time monitoring capabilities—are increasingly being adopted in modern gauges.

Conclusion

In conclusion, differential pressure gauges are vital tools in a multitude of industrial applications. Their ability to provide accurate readings of pressure differences can lead to significant improvements in operational efficiency, safety, and equipment longevity. As technology continues to evolve, the development of smarter, more efficient differential pressure gauges will undoubtedly shape the future of various industries, ensuring that standards for safety and performance are not just met, but exceeded. Understanding and investing in quality differential pressure gauges from reputed manufacturers is essential for any organization looking to optimize its operations and maintain the highest levels of safety and efficiency.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025