Sep . 07, 2024 21:05 Back to list

High-Precision Cryogenic Differential Pressure Gauges for Accurate Measurements

Cryogenic Differential Pressure Gauges Precision in Extreme Conditions

Cryogenic differential pressure gauges play a pivotal role in the measurement and monitoring of pressure differences in environments characterized by extremely low temperatures. These specialized instruments are essential in various applications, including cryogenics, aerospace, and scientific research, where precision and reliability are paramount.

The principle behind differential pressure measurement involves comparing the pressure of two points within a system. This capability is especially crucial in cryogenic applications, where the behavior of gases and liquids can vary dramatically as temperatures approach absolute zero. Traditional pressure gauges often fail in these environments due to their susceptibility to thermal expansion, material fatigue, and other factors that can compromise their accuracy.

Cryogenic differential pressure gauges are engineered to withstand the challenges presented by low-temperature conditions. They utilize materials that maintain integrity and performance at cryogenic temperatures, such as stainless steel or specialized alloys. Furthermore, these gauges often include advanced sensing technologies, such as capacitive or piezoresistive sensors, which offer high sensitivity and minimal drift, ensuring accurate readings over extended periods.

In applications such as liquid nitrogen storage or liquefied natural gas (LNG) processing, maintaining precise control over pressure differences is crucial. For instance, in LNG facilities, even minor variations in pressure can lead to inefficiencies or unsafe conditions. Cryogenic differential pressure gauges enable operators to monitor these fluctuations in real time, allowing for immediate adjustments to maintain optimal performance and safety standards.

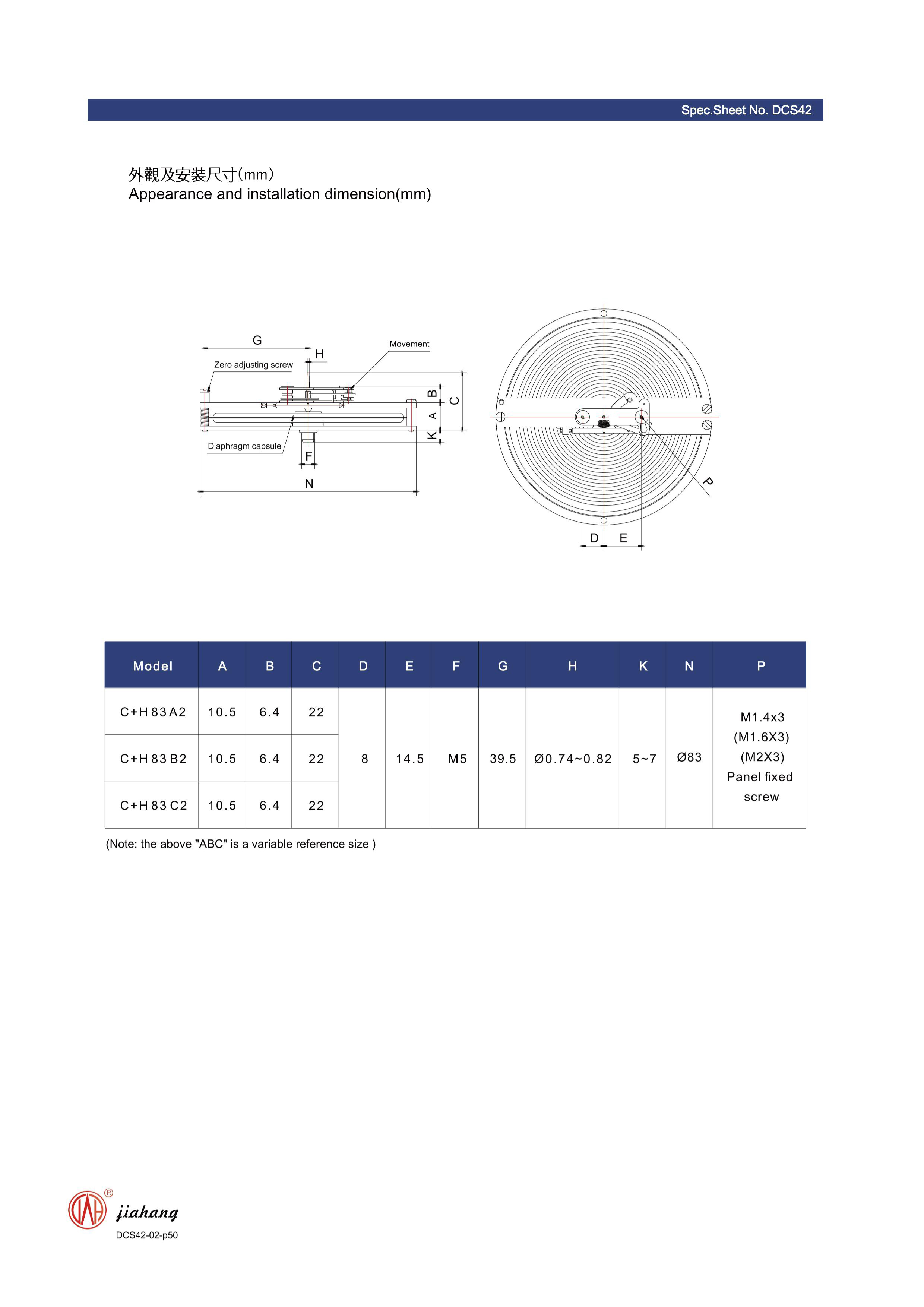

cryogenic differential pressure gauges product

The installation of cryogenic differential pressure gauges is also a critical consideration. These gauges must be positioned correctly to ensure that they measure the intended pressure differential. Additionally, proper thermal insulation and appropriate mounting techniques are necessary to mitigate the effects of external temperature variations, which can introduce errors into pressure readings.

Routine calibration and maintenance are essential for ensuring the long-term reliability of cryogenic differential pressure gauges. Users must adhere to best practices, including regular testing against known standards and inspecting for any signs of wear or damage. By establishing a consistent maintenance schedule, operators can extend the lifespan of these instruments and sustain their performance.

As industries increasingly rely on precise measurements in demanding environments, the demand for advanced cryogenic differential pressure gauges continues to rise. Innovations in materials science and sensor technology are likely to drive the development of even more robust and accurate gauges, empowering researchers and engineers to push the boundaries of what is possible in cryogenic applications.

In conclusion, cryogenic differential pressure gauges are indispensable tools in maintaining safety and efficiency in low-temperature environments. Their specialized design and robust construction allow for accurate and reliable performance, making them vital in various fields from aerospace to medical sciences. As technology progresses, we can expect continued advancements that will enhance the capabilities of these essential instruments.

-

Digital Pressure Gauge RS Components for Semiconductor & Chip Industries

NewsMay.23,2025

-

Industrial Differential Pressure Gauges Global Supplier & Pricelist

NewsMay.23,2025

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025