Dec . 26, 2024 04:33 Back to list

Exporters of Cryogenic Differential Pressure Measurement Solutions for Enhanced Process Control

The Role of Cryogenic Differential Pressure Gauges in Modern Industry

In the modern industrial landscape, where precision and reliability are paramount, cryogenic differential pressure gauges have emerged as vital instruments in various applications. These gauges are specifically designed to function effectively in extremely low-temperature environments, which are commonly encountered in industries dealing with liquefied gases such as nitrogen, oxygen, and natural gas.

Understanding Cryogenic Differential Pressure Gauges

Cryogenic differential pressure gauges are specialized tools used to measure the pressure difference between two points within a system. They are essential for monitoring processes in cryogenic applications, where temperatures can plummet to -150°C (-238°F) or lower. The design of these gauges incorporates materials and mechanisms that can withstand the extreme conditions associated with cryogenic fluids.

The functionality of these gauges is based on the principle of differential pressure measurement, where the difference between the inlet pressure and outlet pressure is evaluated to ensure that systems operate efficiently and safely. This measurement is critical, as even minute variations can indicate failures, leaks, or other potentially hazardous conditions.

Applications Across Industries

The applications of cryogenic differential pressure gauges span numerous sectors, including aerospace, medical, energy, and food processing.

1. Aerospace In the aerospace sector, cryogenic gauges play a crucial role in monitoring fuel systems that utilize liquid oxygen or hydrogen. These gauges ensure that propulsion systems maintain optimal operating conditions, thus improving efficiency and safety during flight.

2. Medical In medical applications, particularly in the storage and transport of biological samples or pharmaceuticals, maintaining appropriate conditions is essential. Cryogenic gauges help in monitoring the storage of cryogenically preserved cells and tissues, ensuring they remain within safe temperature ranges.

3. Energy The energy sector, especially in natural gas and liquefied natural gas (LNG) production, relies heavily on pressure gauges for safety and efficient operation. Cryogenic differential pressure gauges allow operators to monitor various stages of the gas handling processes, helping to prevent leaks and ensure that systems are operating within designed pressure limits.

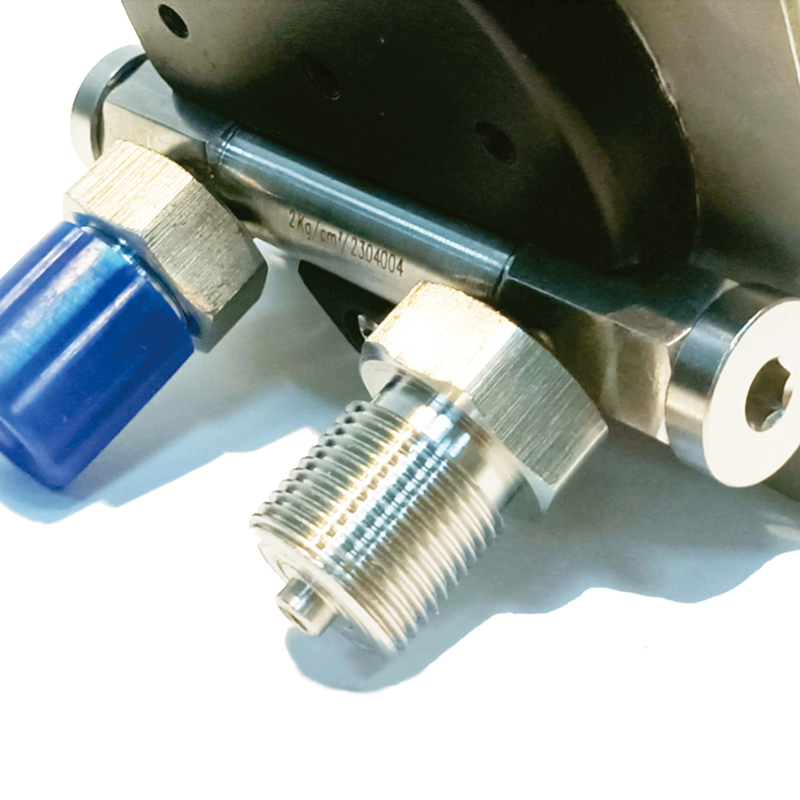

cryogenic differential pressure gauge exporters

4. Food Processing In the food industry, cryogenic technology is used for rapid freezing processes to preserve the quality and shelf life of products. Monitoring the pressure in cryogenic freezers is essential, and pressure gauges help maintain these systems effectively.

Benefits of Using Cryogenic Differential Pressure Gauges

The benefits of implementing cryogenic differential pressure gauges are multifaceted. Primarily, they provide accurate measurements that are crucial for safety-critical operations. By ensuring that systems are operating under the correct pressure conditions, industries can prevent catastrophic failures or costly downtime.

Furthermore, the reliability of cryogenic gauges contributes to the overall efficiency of industrial processes. Maintaining optimal differential pressures allows for better control of flow rates, which can lead to enhanced performance and minimized waste.

Additionally, technological advancements have led to the development of more compact and sensitive gauges, which can provide real-time monitoring and diagnostics. This capability allows for immediate responses to any detected irregularities, ultimately leading to enhanced operational safety and efficiency.

Choosing the Right Exporter

When selecting a cryogenic differential pressure gauge, it is crucial to choose a reputable exporter. Factors to consider include the exporter’s experience, the quality of their products, and their customer service. It is also beneficial to look for exporters that offer a range of gauges to ensure compatibility with various applications and environments.

Furthermore, considering compliance with industry standards and certifications can enhance confidence in the products. Many exporters will provide detailed specifications, product testing results, and application recommendations, which can be invaluable when making a purchase decision.

Conclusion

Cryogenic differential pressure gauges are indispensable tools in the realm of modern industry. Their ability to function accurately in extreme temperatures makes them essential for ensuring safety and efficiency across various applications. As industries continue to evolve and expand, the demand for these specialized gauges is likely to grow, further emphasizing the need for reliable and skilled exporters in the market. By investing in high-quality cryogenic differential pressure gauges, industries can enhance their operational reliability and overall safety.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025