Dec . 12, 2024 20:54 Back to list

Custom Diaphragm Pressure Gauges for Precision Measurement Solutions

Custom Diaphragm Pressure Gauge An Overview

In various industrial applications, accurate measurement of pressure is crucial for maintaining safety, efficiency, and operational integrity. One of the specialized instruments used for this purpose is the custom diaphragm pressure gauge. This article delves into the functionality, design, and benefits of custom diaphragm pressure gauges, explaining why they are essential in many sectors.

Understanding Diaphragm Pressure Gauges

A diaphragm pressure gauge functions by measuring the pressure exerted on a diaphragm—a flexible membrane—within the gauge. When pressure is applied, the diaphragm bends, and this deflection is translated into a readable value on the gauge's dial. The primary advantage of a diaphragm pressure gauge is its ability to handle a wide range of pressures, including low pressures, which are often difficult for other gauge types to measure accurately.

The diaphragm itself is usually made of materials such as stainless steel, brass, or other alloys that can withstand harsh environments. Depending on the application, gauges can be designed to handle corrosive substances, high temperatures, and extreme pressures.

The Need for Customization

While standard diaphragm pressure gauges are suitable for many applications, specific industries often require bespoke solutions to meet their unique challenges. Custom diaphragm pressure gauges allow for modifications that enhance their functionality based on the specific environment in which they will be deployed.

custom diaphragm pressure gauge

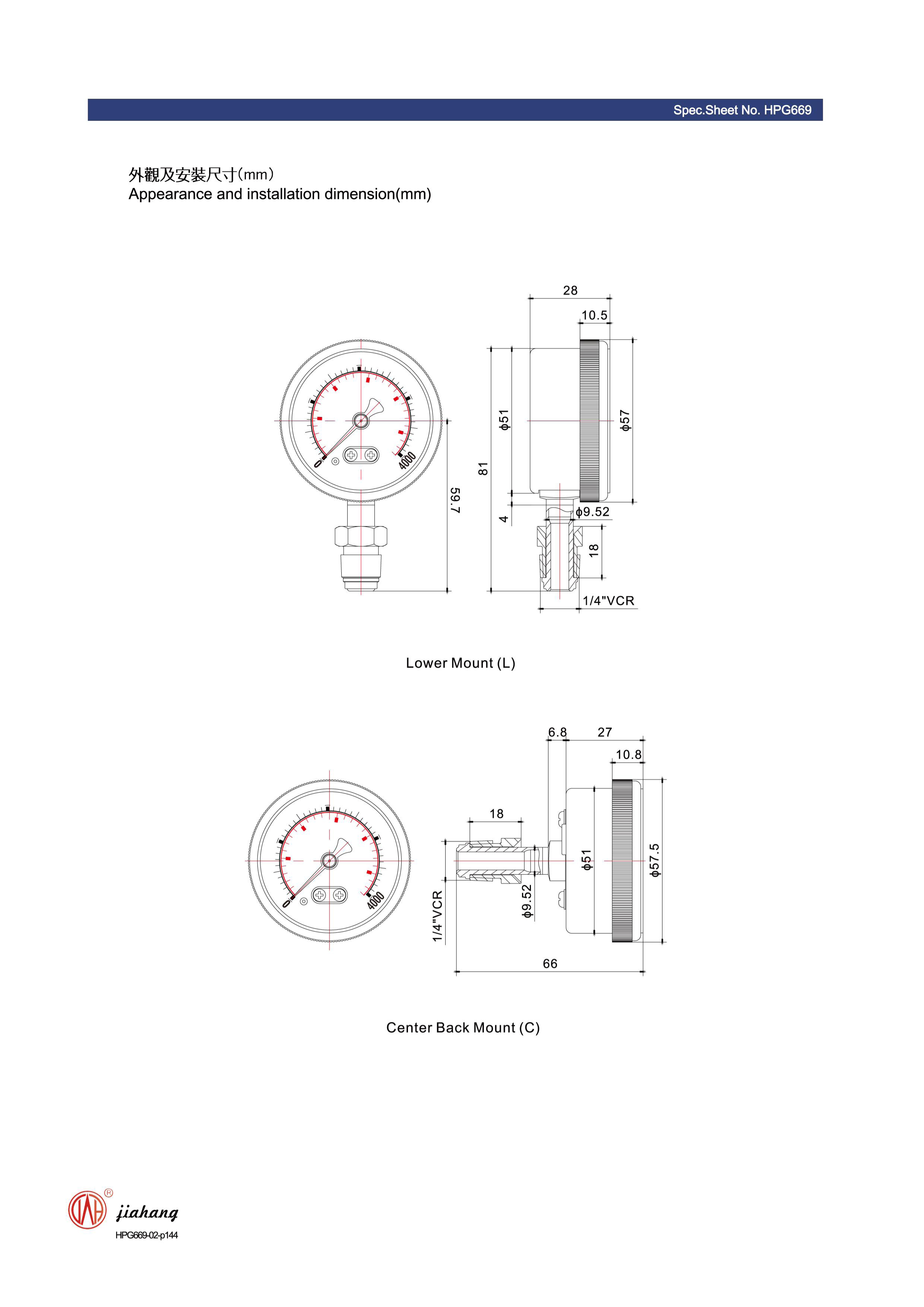

Customization can include various parameters - Material Selection Custom gauges can be manufactured from materials that are resistant to specific chemicals or temperature extremes, increasing durability and accuracy. - Pressure Range Depending on the application, the pressure range can be tailored to ensure the gauge operates optimally for particular conditions. - Size and Port Type Different installations may require different sizes and types of pressure ports. Custom solutions can accommodate these requirements. - Accuracy Calibration Customization allows for precise calibration, ensuring that the gauge delivers accurate readings suited to the specific operational context.

Industries that benefit from custom diaphragm pressure gauges include oil and gas, pharmaceuticals, food processing, and manufacturing. Each of these sectors has unique demands, making customized solutions practical and often necessary.

Advantages of Custom Diaphragm Pressure Gauges

1. Precision in Measurement Custom gauges can be designed to offer high precision, crucial for processes that require strict adherence to specifications. 2. Enhanced Durability By using specialized materials and coatings, custom gauges can perform better in extreme conditions, leading to extended service life and lower replacement costs. 3. Versatility These gauges can be tailored for a variety of applications, making them suitable for diverse industries – from monitoring HVAC systems to measuring pressure in petrochemical processes. 4. Improved Safety Accurate pressure measurements reduce the risk of overpressure situations, leading to safer operational environments. 5. Cost-Effectiveness While there may be a higher upfront cost for custom gauges, their increased reliability and performance can result in lower overall operational costs due to reduced downtimes and improved efficiency.

Conclusion

The importance of customized diaphragm pressure gauges in various industrial applications cannot be overstated. They not only provide precise pressure measurements but also cater to the specific challenges posed by different environments and substances. By investing in custom solutions, industries can enhance operational safety, improve efficiency, and ensure that their processes run smoothly.

Ultimately, the choice to implement a custom diaphragm pressure gauge is a strategic one, aimed at achieving operational excellence. With the right design and materials, these gauges can serve as invaluable tools in any industrial context, paving the way for a future where pressure monitoring is seamless and precise. Whether in the heart of a bustling manufacturing plant or in the complexity of a chemical processing facility, the reliability offered by custom diaphragm pressure gauges is an essential component of modern industry.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025