Oct . 10, 2024 09:43 Back to list

Custom Pressure Gauge Manufacturer Specializing in Diaphragm Technology for Precise Measurements

Selecting a Custom Diaphragm Pressure Gauge Manufacturer

When it comes to precision measurement in various industrial applications, the importance of choosing the right pressure gauge cannot be overstated. Among the different types of pressure measuring instruments, diaphragm pressure gauges stand out for their reliability and accuracy, particularly in challenging environments. This article explores the key considerations and benefits of selecting a reputable custom diaphragm pressure gauge manufacturer.

Understanding Diaphragm Pressure Gauges

Diaphragm pressure gauges operate on the principle of using a flexible diaphragm to sense pressure. They are particularly useful for measuring low and high pressures in gases and liquids. The diaphragm expands or contracts in response to pressure changes, translating these mechanical movements into a readable output. This design offers several advantages, including resilience against corrosive media, high accuracy, and the ability to withstand vibration and shock, which are common in industrial settings.

Benefits of Customization

One of the significant advantages of partnering with a custom diaphragm pressure gauge manufacturer is the ability to tailor products specifically to your needs. Standard pressure gauges may not always fit unique application requirements. Customization can encompass various aspects, including

1. Material Selection Depending on the process fluid, you may require specific materials that resist corrosion, such as stainless steel, Monel, or Teflon.

2. Pressure Range Custom manufacturers can provide gauges across a broader range of pressures than typical off-the-shelf models, ensuring that you have accurate readings without the risk of damage from overpressure.

3. Connection Types Different applications might necessitate various types of fittings. Manufacturers can incorporate specific connection types that align with your system's requirements.

4. Size and Design The physical dimensions of gauges can sometimes be determined by available space in equipment or panels. Custom manufacturers can design gauges that fit perfectly into your equipment while maintaining operational efficiency.

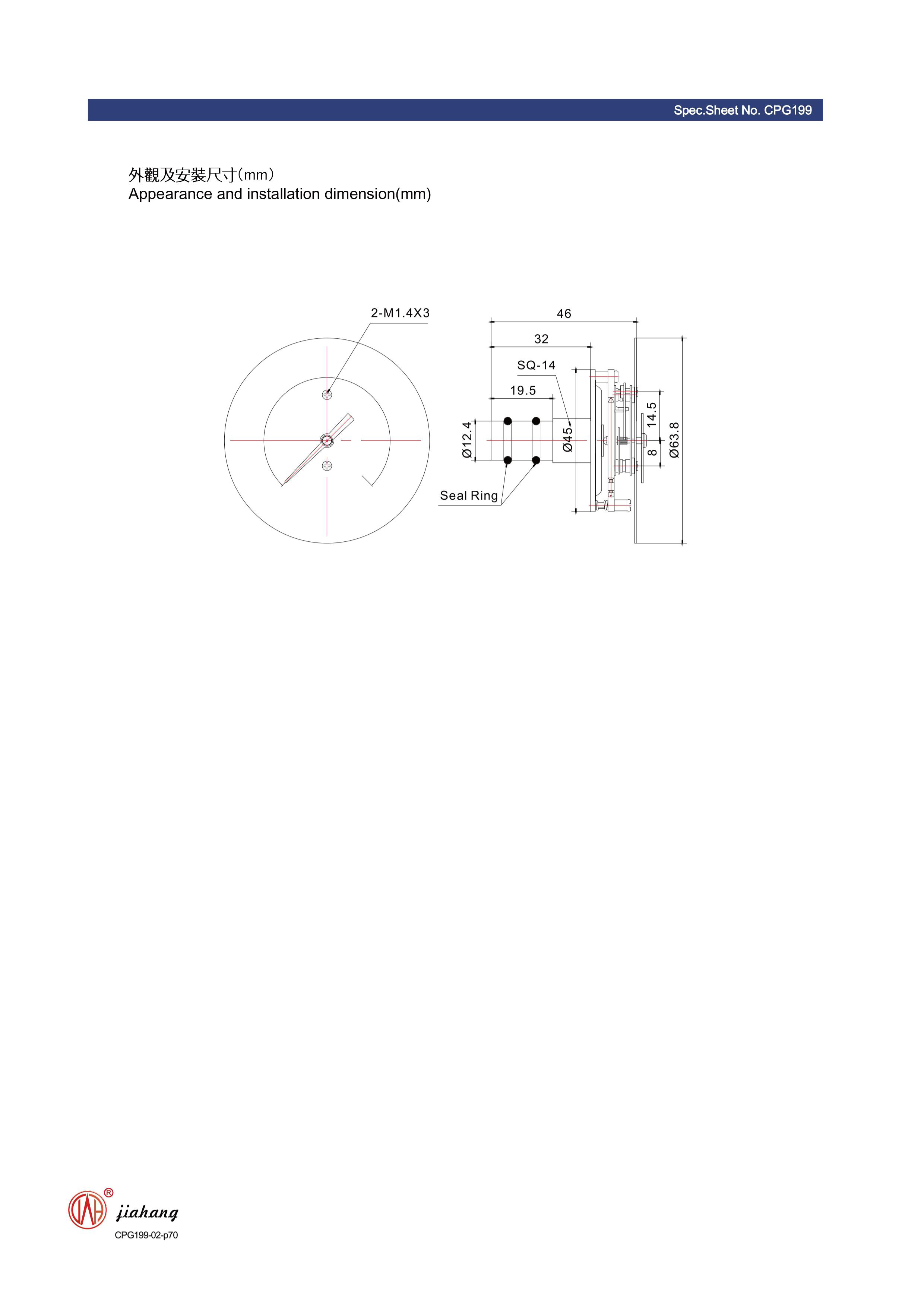

custom diaphragm pressure gauge manufacturer

5. Special Features Enhanced functionalities such as electrical outputs, built-in alarms, or remote monitoring capabilities can be integrated, making the gauges more versatile for modern applications.

Importance of Choosing the Right Manufacturer

Choosing the right manufacturer is crucial for getting the most out of your diaphragm pressure gauges. Here are a few pointers to consider

- Experience and Reputation Look for a manufacturer with a proven track record in producing high-quality pressure gauges. Consider customer reviews and case studies to gauge their reliability.

- Quality Control A reputable manufacturer should have stringent quality control procedures in place, ensuring product consistency and adherence to industry standards.

- Technical Support Post-purchase technical support is essential. A manufacturer that offers excellent customer service can assist with installation, maintenance, and troubleshooting.

- Flexibility and Lead Times It’s important to choose a manufacturer that can accommodate your timelines and adapt to any changes in specifications without affecting delivery schedules.

Conclusion

Selecting a custom diaphragm pressure gauge manufacturer is a strategic decision that can dramatically enhance the accuracy and reliability of your pressure measurement systems. By choosing a provider that can deliver tailor-made solutions, you can ensure that your applications run smoothly and efficiently. Take the time to research and partner with a manufacturer that aligns with your specific needs, and you will reap the benefits of high-quality, customized pressure measurement solutions.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025