Nov . 14, 2024 22:17 Back to list

custom diaphragm vacuum pressure gauge

Custom Diaphragm Vacuum Pressure Gauges Precision and Reliability for Industrial Applications

In the world of industrial measurement and control, precision is paramount. One of the critical tools for measuring vacuum pressure in various applications is the diaphragm vacuum pressure gauge. These gauges are essential for monitoring and maintaining the efficiency of vacuum systems in industries such as pharmaceuticals, food processing, and manufacturing. This article delves into the significance of custom diaphragm vacuum pressure gauges, their working principles, advantages, and the diverse industries they serve.

Understanding Diaphragm Vacuum Pressure Gauges

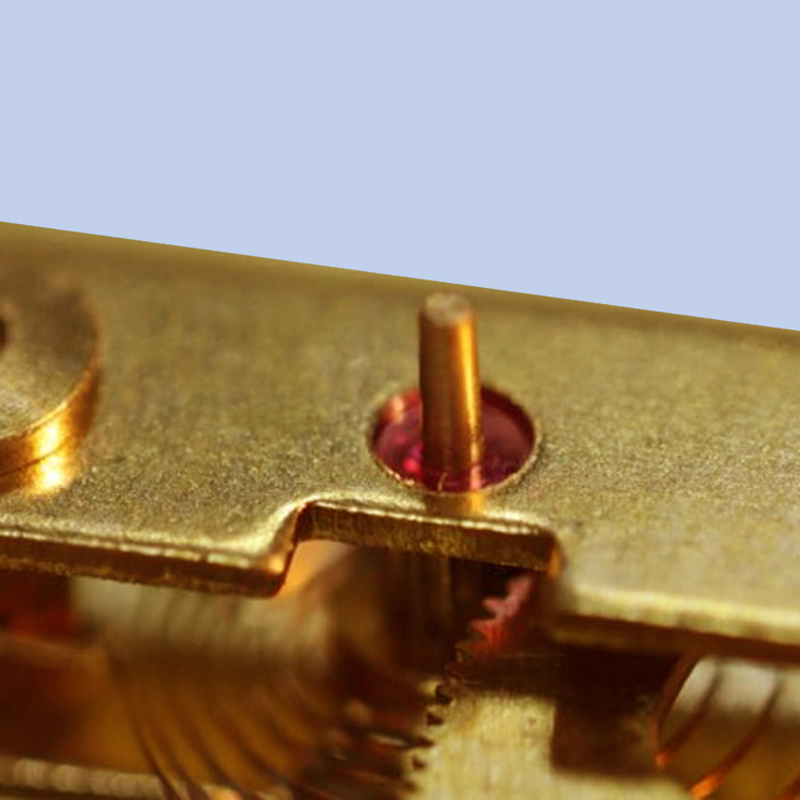

A diaphragm vacuum pressure gauge operates on the principle of deflection of a flexible diaphragm due to changes in pressure. When a vacuum is applied, the diaphragm flexes, which then translates into a mechanical movement. This movement is often amplified through a linkage mechanism that drives a pointer on a dial or produces an electronic signal for digital readouts. The calibration of these gauges ensures accurate readings, making them indispensable for critical applications.

Customization for Specific Applications

One of the outstanding features of diaphragm vacuum pressure gauges is their ability to be customized to meet specific application requirements. Various industries often contend with unique challenges such as extreme temperatures, corrosive environments, or specific pressure ranges. Custom diaphragm gauges can be designed with materials that withstand harsh chemicals or elevated temperatures, ensuring longevity and reliability.

For instance, a pharmaceutical company may require a pressure gauge that not only measures vacuum accurately but also meets stringent hygienic design requirements to prevent contamination in drug manufacturing processes. By opting for a customized solution, companies can thus enhance their operational efficiency while ensuring compliance with industry standards.

Advantages of Custom Diaphragm Gauges

1. Accuracy and Precision Custom diaphragm vacuum pressure gauges can be meticulously calibrated for precise measurements, ensuring that systems operate efficiently and safely. This accuracy is crucial in preventing equipment damage and maintaining product quality.

2. Durability Standard gauges may not endure intense conditions; however, custom gauges made from durable materials can withstand extreme environmental factors, enhancing lifespan and reliability.

3. Flexibility in Design Manufacturers can design gauges that fit specific installation requirements, including size, shape, and mounting configurations. This flexibility means that companies can integrate these gauges into unique setups without compromising performance.

custom diaphragm vacuum pressure gauge

4. Cost-effectiveness While custom gauges may seem more expensive initially, the long-term benefits, including reduced downtime, lower maintenance costs, and improved product quality, lead to better overall cost-effectiveness.

5. Advanced Features Custom gauges can include advanced features such as digital displays, remote monitoring capabilities, and integrated alarm systems, providing operators with real-time data and alerts for better decision-making.

Applications Across Industries

Custom diaphragm vacuum pressure gauges are versatile tools employed across multiple sectors

- Pharmaceuticals In drug manufacturing, precision and hygiene are critical. Custom gauges help monitor vacuum levels during processes such as freeze-drying and filtration.

- Food Processing Maintaining vacuum levels during food packaging is vital for extending shelf life. Customized gauges ensure that vacuum sealing processes are carried out effectively.

- Chemical Processing Custom gauges designed with materials resistant to corrosive chemicals are essential in monitoring vacuum systems in chemical industries, preventing leaks and ensuring safety.

- Manufacturing Precision vacuum pressure measurement is crucial in industries like electronics, where vacuum systems are used in semiconductor manufacturing and coating processes.

- Environmental Monitoring In the realm of environmental science, custom gauges can be utilized for measuring vacuum levels in controlled environments like landfill sites and soil remediation projects.

Conclusion

Custom diaphragm vacuum pressure gauges are invaluable assets in various industrial applications, providing reliable and precise measurement capabilities tailored to specific needs. The ability to customize these gauges not only enhances accuracy and durability but also ensures compliance with stringent industry regulations. As technology progresses, the demand for precision measurement tools will likely rise, making custom diaphragm vacuum pressure gauges an indispensable part of the industrial toolkit. By investing in high-quality custom gauges, organizations can improve operational efficiency, product quality, and ultimately, their bottom line.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025