Dec . 07, 2024 06:41 Back to list

customized diaphragm seal pressure gauge exporters

The Rise of Customized Diaphragm Seal Pressure Gauge Exporters

In today's industrial landscape, precision measurement of pressure is critical across various sectors, including oil and gas, food and beverage, pharmaceuticals, and chemical processing. A key component in achieving accurate pressure readings is the diaphragm seal pressure gauge, which ensures reliable performance even under challenging conditions. As global demand for such instruments continues to surge, the role of customized diaphragm seal pressure gauge exporters has become increasingly prominent.

Understanding Diaphragm Seal Pressure Gauges

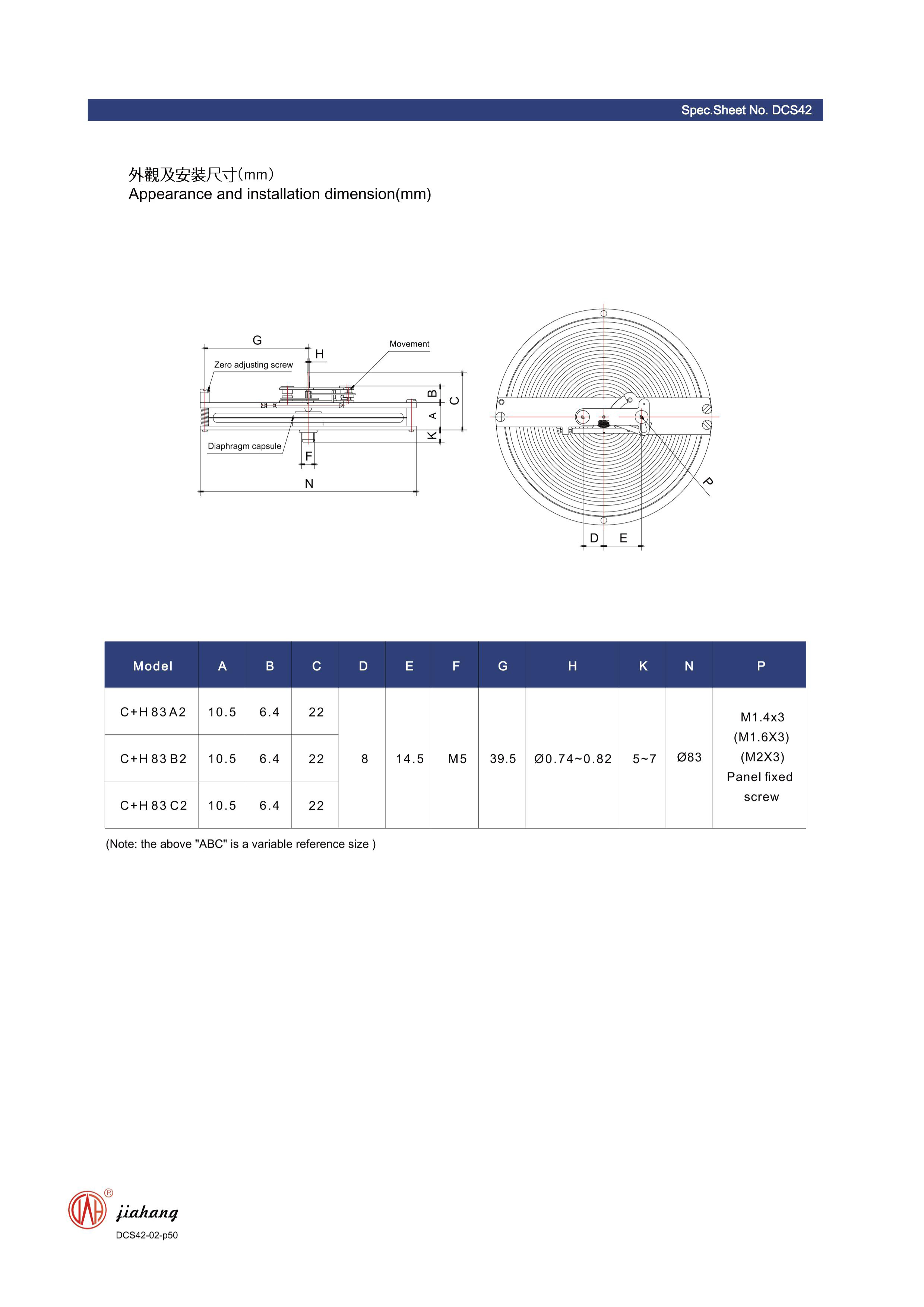

A diaphragm seal pressure gauge consists of a pressure sensing element, typically a diaphragm made from elastic materials, and a pressure gauge that translates the mechanical movement of the diaphragm into a pressure reading. The primary function of the diaphragm is to isolate the sensing mechanism from the medium being measured, making it ideal for corrosive or viscous fluids, slurries, or high-temperature applications. This specialized design not only protects the gauge but also ensures that users receive accurate readings without the risk of blockage or contamination.

The Need for Customization

While standard pressure gauges meet general requirements, many industries face situations that necessitate tailored solutions. For instance, the chemical industry may require pressure gauges that resist specific corrosive substances, while the food industry must adhere to strict hygiene standards. Consequently, the demand for customized diaphragm seal pressure gauges has risen significantly. By working with exporters who specialize in bespoke solutions, businesses can obtain gauges that perfectly align with their operational needs, providing better reliability and enhancing overall safety.

Key Features of Customized Diaphragm Seal Pressure Gauges

1. Material Selection One of the most critical aspects of customization is the selection of materials. Exporters often offer a range of options, such as stainless steel, Hastelloy, or Monel, which can withstand different chemical environments and temperature ranges. The right material choice ensures longevity and performance.

2. Pressure Range Every application has its specific pressure requirements. Custom exporters can provide gauges calibrated for low, medium, or high-pressure ranges, ensuring that the readings are both accurate and relevant.

customized diaphragm seal pressure gauge exporters

3. Size and Scale Options Depending on the installation space and user preferences, customized gauges can be produced in various sizes, including dial diameter and scale markings. This flexibility assists in straightforward integration into existing systems.

4. Connection Types Different applications may require specific connection types or configurations. Custom exporters can provide adapters and fittings to ensure compatibility with existing pipes or equipment, minimizing the risk of leaks or failures.

5. Protection and Enclosure Industries operating in harsh environments may require additional protective features to safeguard the gauges. Customized solutions can include features like protective coatings, housings, or vibration-resistant designs, thereby increasing durability.

The Exporter Landscape

The globalization of trade has allowed a myriad of exporters to enter the market, catering to diverse industries worldwide. Companies specializing in custom diaphragm seal pressure gauges can leverage advanced technology and engineering expertise to develop innovative solutions that meet the most stringent requirements. Furthermore, exporting provides these businesses access to a more extensive customer base, enhancing competition and driving the development of high-quality products.

Maintaining strong quality assurance protocols is paramount for exporters to ensure that every customized gauge meets international standards. Many exporters are also investing in research and development to enhance product capabilities, focusing on technology integration, such as digital pressure monitoring systems and remote monitoring solutions.

Conclusion

The importance of customized diaphragm seal pressure gauge exporters cannot be overstated. As industries evolve and face new challenges, the need for precision measurement tools that can perform across diverse conditions is more critical than ever. Customized solutions not only enhance operational efficiency but also improve safety, reliability, and compliance with industry regulations.

For industries looking to invest in high-quality diaphragm seal pressure gauges, collaborating with experienced exporters who understand their unique requirements can lead to tailored solutions that are both functional and durable. As the demand for custom solutions continues to grow, the industry is poised for innovation, presenting opportunities for businesses to gain a competitive edge in an increasingly complex market. In this dynamic landscape, customized diaphragm seal pressure gauge exporters are indeed the unsung heroes ensuring accurate and reliable pressure readings around the globe.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025