Oct . 09, 2024 07:05 Back to list

Custom Diaphragm Pressure Gauge for Precision Measurement in Various Applications

Custom Mass Diaphragm Pressure Gauge Precision Measurement for Diverse Applications

In the world of industrial measurements, precision and reliability are paramount. Among various instruments designed for pressure measurement, the custom mass diaphragm pressure gauge stands out as an exceptional choice for many applications. This specialized device provides accurate readings and durability, making it indispensable in sectors such as oil and gas, pharmaceuticals, food processing, and more.

A diaphragm pressure gauge operates based on the principle of deflection. The core element, a flexible diaphragm, responds to changes in pressure by bending. This movement is then translated into a readable measurement. Custom-designed diaphragms can be tailored to specific applications, ensuring that the gauge can measure a wide range of pressures accurately, whether in vacuum conditions or high-pressure environments.

One of the significant advantages of using a custom mass diaphragm pressure gauge is its ability to withstand harsh conditions. Industrial settings often involve exposure to corrosive substances, extreme temperatures, or high levels of vibration. Manufacturers of these gauges can utilize various materials, such as stainless steel or specialized alloys, to enhance their resistance to wear and tear. Additionally, custom designs can help mitigate the effects of dynamic pressure fluctuations, ensuring the gauge maintains accuracy over time.

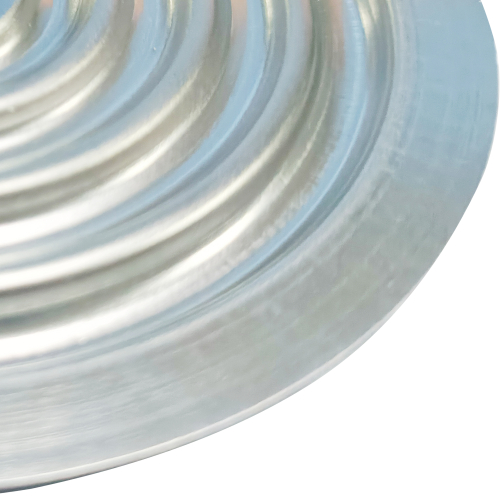

custom mass diaphragm pressure gauge

Another notable feature of custom mass diaphragm pressure gauges is their versatility. These instruments can be tailored to meet specific size and scale requirements, making them suitable for both small and large applications. For instance, in the food and beverage industry, sanitary designs are crucial for compliance with health regulations. A custom gauge can be engineered to include hygienic connections and materials that ensure safety without compromising measurement accuracy.

In sectors where precision is critical, such as in pharmaceutical manufacturing, the importance of reliable pressure measurement cannot be overstated. A custom diaphragm pressure gauge can offer the required sensitivity and accuracy to monitor processes closely, thereby ensuring quality control in the final product. Furthermore, integrating advanced technologies, such as digital readouts and data logging capabilities, elevates the functionality of these gauges, allowing operators to make informed decisions based on real-time data.

Moreover, customization is not just limited to the physical attributes of the gauge; it can also extend to the calibration and scale. Depending on the specific pressure ranges required by an application, manufacturers can adjust the calibration to deliver precise readings that cater to a unique set of operational parameters.

In conclusion, the custom mass diaphragm pressure gauge is an essential instrument for achieving precision and reliability in industrial pressure measurement. Its durability, adaptability to various applications, and ability to function under challenging conditions make it a preferred choice for many industries. By investing in a custom solution, businesses can ensure they meet their specific needs and maintain high standards for quality and safety in their processes. With continuous advancements in technology and materials, the prospects for custom mass diaphragm pressure gauges are bright, paving the way for even more innovative applications in the future.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025