Sep . 22, 2024 18:57 Back to list

custom wika differential pressure gauge with switch

The Importance of Custom WIKA Differential Pressure Gauges with Switches

In various industrial applications, monitoring and controlling pressure is crucial for ensuring operational efficiency and safety. One of the essential tools for achieving accurate pressure measurements is the differential pressure gauge. Among the various manufacturers, WIKA stands out, particularly with its custom differential pressure gauges equipped with switches.

Differential pressure gauges are designed to measure the difference in pressure between two points in a system. This capability is essential in applications such as filter monitoring, level measurement in tanks, and air flow monitoring in HVAC systems. The WIKA differential pressure gauge not only provides precise measurements but can also be tailored to meet specific requirements of different industries.

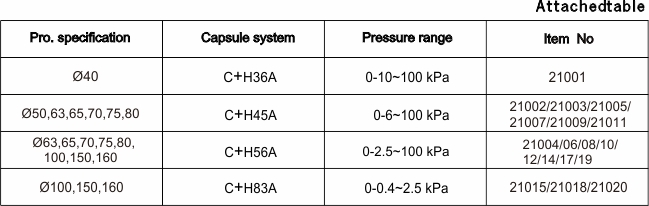

What sets WIKA apart is their customization options. Custom WIKA differential pressure gauges can be designed to fit the unique specifications of a particular application. This customization can include modifications in size, scale, material, and pressure ranges. When paired with switches, these gauges offer an additional layer of functionality, enabling users to automate processes and respond promptly to pressure changes.

custom wika differential pressure gauge with switch

The incorporation of switches into differential pressure gauges enhances safety and operational efficiency. For instance, in filter applications, a pressure switch can trigger an alarm or automated cleaning process when the differential pressure exceeds a predetermined threshold. This helps prevent equipment damage and ensures optimal performance without requiring constant manual monitoring.

Moreover, WIKA's custom differential pressure gauges with switches are built to withstand harsh environments. They are available in a variety of materials suitable for corrosive or extreme temperature conditions, ensuring durability and reliability. Whether it’s for chemical processing, oil and gas, or HVAC applications, these gauges can be tailored to resonate with the specific challenges of the industry.

To illustrate, consider a waste management plant where differential pressure monitoring is essential. The custom WIKA differential pressure gauge can be configured to measure the pressure drop across a filter bed. When the differential pressure reaches a critical point, the integrated switch activates, alerting the system to initiate cleaning or replacement procedures. This not only optimizes the operational process but also extends the lifespan of the equipment.

In conclusion, custom WIKA differential pressure gauges with switches are vital tools in modern industrial applications. Their ability to provide accurate measurements, coupled with customizable features and integrated switch functionality, allows companies to enhance safety, reliability, and efficiency. Investing in such precision instruments is not only a choice for accuracy but also a commitment to maintaining the highest industrial standards. As industries continue to evolve, the significance of tailored solutions like WIKA's differential pressure gauges will only grow, ensuring that operations continue to run smoothly and without interruption.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025