Aug . 27, 2024 18:58 Back to list

Diaphragm Seal Type Pressure Gauge Exporters

Diaphragm Seal Type Pressure Gauge Exporters An Overview

In the realm of industrial measurement and instrumentation, diaphragm seal type pressure gauges have emerged as essential tools for various applications. These specialized pressure gauges are designed to measure pressure in challenging environments where traditional gauges may fail, such as in extreme temperatures, corrosive substances, or high-viscosity fluids. This article explores the significance of diaphragm seal type pressure gauges and the role of exporters in this niche market.

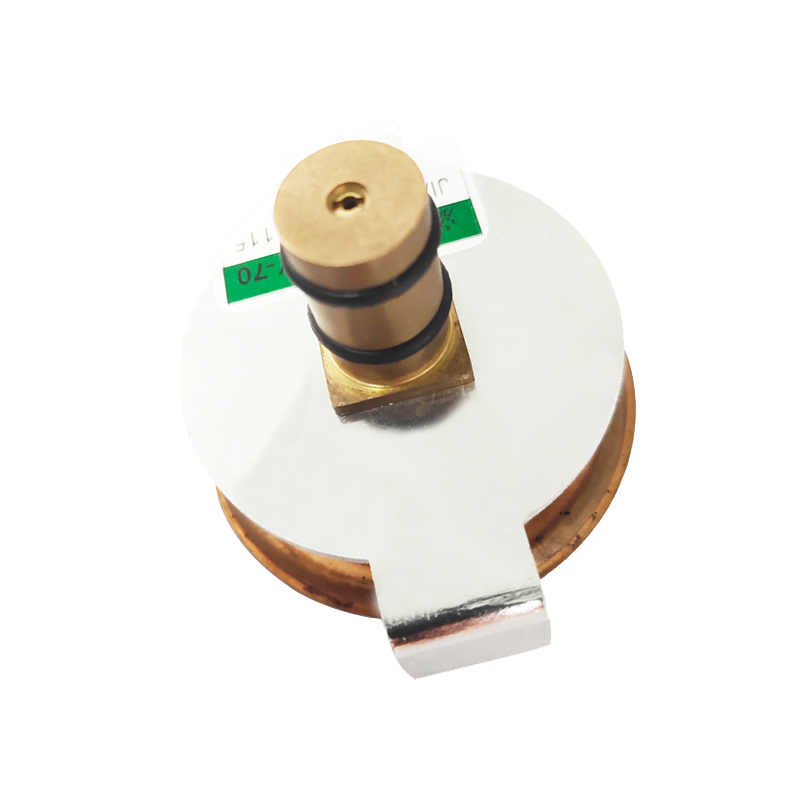

Diaphragm seal type pressure gauges operate on a simple yet effective principle. They utilize a flexible diaphragm to separate the measuring fluid from the pressure sensor. When pressure is applied, the diaphragm deflects, transmitting the pressure to the sensor, which in turn provides a measurement reading. This design allows for accurate pressure readings without direct exposure of the pressure sensor to harsh media.

The need for diaphragm seal type pressure gauges is increasingly evident across various industries, including oil and gas, chemical processing, food and beverage, and pharmaceuticals. In these sectors, the integrity of the measurement instrument is crucial to ensure safety, compliance, and operational efficiency. For instance, in the chemical industry, gauges must withstand corrosive materials while maintaining precision. Similarly, in the food and beverage industry, hygiene standards dictate the use of gauges that do not contaminate the product.

diaphragm seal type pressure gauge exporters

As the demand for high-quality diaphragm seal type pressure gauges grows, so does the role of exporters in delivering these specialized instruments to global markets. Exporters play a critical role by connecting manufacturers with customers worldwide, ensuring that industries have access to the latest technologies and products that meet their specific needs.

Leading exporters in this field understand the importance of quality and reliability. Many of them work closely with manufacturers to ensure that every gauge meets stringent quality control standards. They often provide a range of options tailored to different applications, including various materials for diaphragm seals, depending on the media being measured. For example, stainless steel may be used for corrosion resistance, while elastomers might be selected for flexibility in specific applications.

Moreover, exporters contribute to the growth of the diaphragm seal type pressure gauge market by facilitating technical support and expertise. They assist clients in selecting the appropriate gauge for their requirements and provide training on installation and maintenance. This added value helps end-users maximize the life and performance of their pressure gauges, making them a vital partner in industrial operations.

In conclusion, diaphragm seal type pressure gauge exporters play an essential role in the global instrumentation market. By offering high-quality, specialized products and supporting their clients with expertise and service, they ensure that industries can rely on accurate measurements in even the most challenging environments. As industrial applications continue to evolve, the importance of these exporters will only increase, paving the way for advancements in pressure measurement technology.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025