Oct . 07, 2024 18:43 Back to list

diaphragm capsule pressure gauge exporters

The Role of Diaphragm Capsule Pressure Gauges in Industry

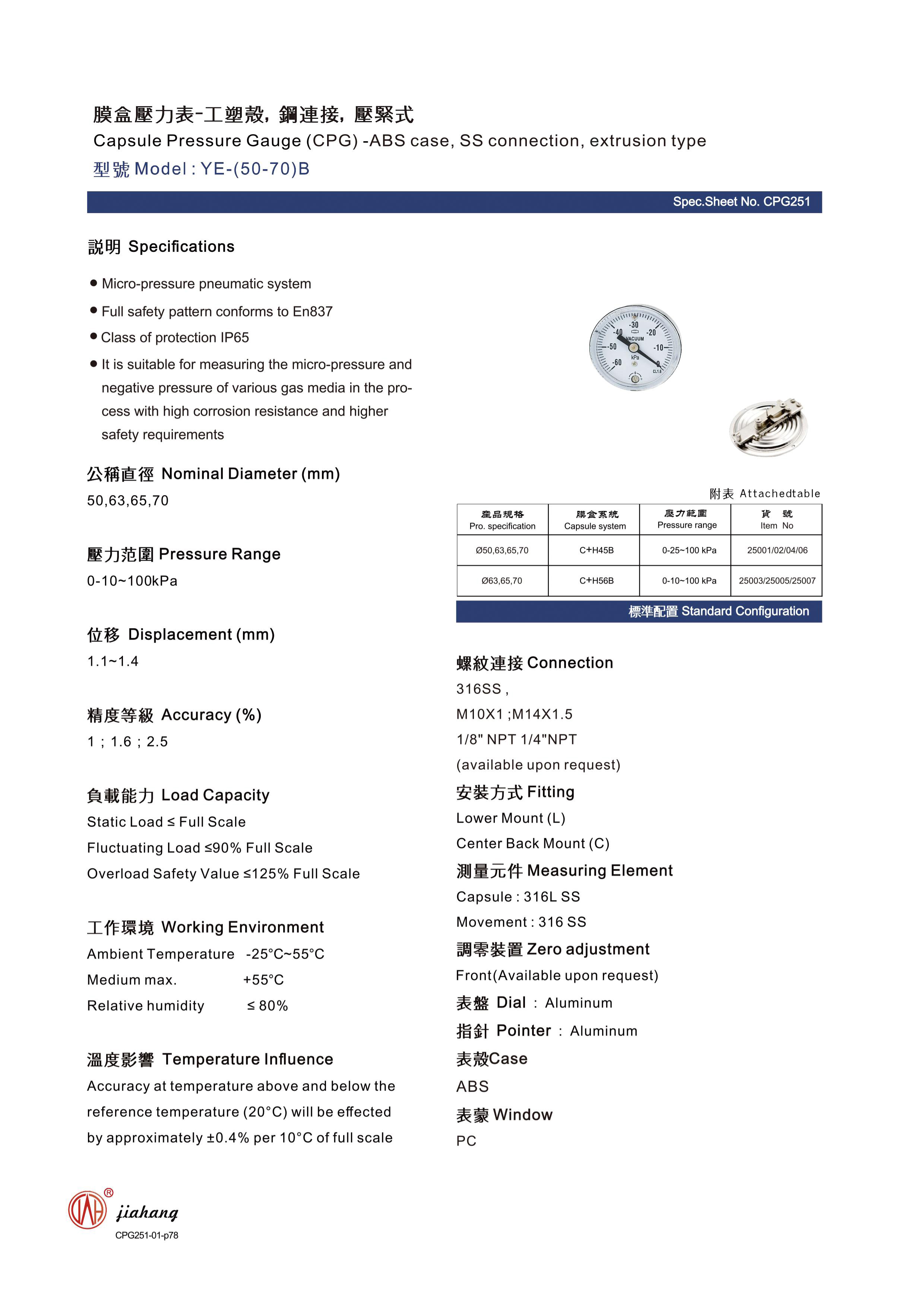

Diaphragm capsule pressure gauges are essential instruments used in various industries for measuring and monitoring pressure levels. Their design features a flexible diaphragm that deflects under pressure, providing accurate readings essential for safe and efficient operations. This article explores the significance of diaphragm capsule pressure gauges, their applications, and the role of exporters in the global market.

Diaphragm capsule pressure gauges are particularly valued for their ability to measure low to medium pressures, making them ideal for a wide range of applications, from HVAC systems to process industries. The construction of these gauges typically involves durable materials such as stainless steel, which not only enhances their reliability but also ensures they can withstand harsh environmental conditions. This durability is crucial in industries like chemical manufacturing, where extreme temperatures and corrosive substances are commonplace.

One of the most notable characteristics of diaphragm capsule pressure gauges is their accuracy. When measuring pressure, precision is paramount, as even slight deviations can lead to significant operational issues. These gauges are designed to provide consistent and accurate readings, allowing operators to make informed decisions based on reliable data. For example, in the food and beverage industry, maintaining specific pressure levels is critical for ensuring product quality and safety.

diaphragm capsule pressure gauge exporters

The global market for diaphragm capsule pressure gauges is thriving, driven by increasing industrial activities and the growing demand for reliable measurement tools. Exporters play a vital role in this market by facilitating the distribution of these gauges to various regions around the world. They not only supply high-quality products but also offer essential support services such as installation, maintenance, and calibration. By ensuring that these instruments operate correctly, exporters help industries maintain efficiency and safety in their processes.

Additionally, the trend toward automation in manufacturing is boosting the demand for advanced pressure measurement technologies. Many exporters are responding to this trend by incorporating digital technologies into diaphragm capsule pressure gauges, enhancing their functionality and ease of use. These smart gauges often come equipped with features like remote monitoring and data logging, allowing for greater efficiency and troubleshooting capabilities.

In conclusion, diaphragm capsule pressure gauges are indispensable tools in modern industry, ensuring accurate and reliable pressure measurements across various applications. As the global market continues to expand, the role of exporters becomes increasingly important in providing these essential instruments, thus supporting industries in their pursuit of efficiency and safety. Whether for low-pressure applications in delicate processes or robust environments, the significance of these gauges cannot be overstated.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025