Nov . 21, 2024 06:52 Back to list

diaphragm pressure sensing element supplier

Understanding Diaphragm Pressure Sensing Elements Suppliers and Their Importance

In the realm of industrial and scientific measurements, diaphragm pressure sensing elements play a crucial role. These devices are widely employed for measuring pressure in various applications ranging from HVAC systems to automotive industries, medical devices, and more. The diaphragm pressure sensor operates based on the deflection of a flexible diaphragm under pressure, translating mechanical changes into readable electrical signals. This article outlines the significance of diaphragm pressure sensing elements and highlights important considerations when selecting a supplier.

The Functionality of Diaphragm Pressure Sensors

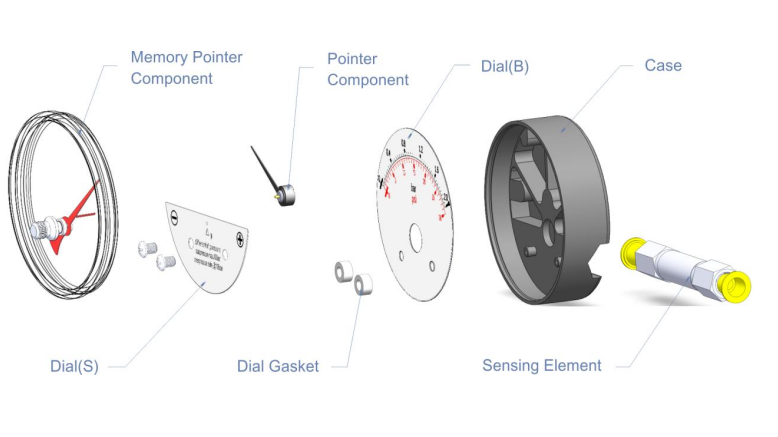

Diaphragm pressure sensors are characterized by their design, which includes a thin membrane (the diaphragm) that is placed between the pressure source and the sensor. When pressure is applied, the diaphragm flexes, and this deflection is measured using various transduction principles, including strain gauges, capacitive methods, or piezoelectric elements. The choice of transduction method impacts factors such as accuracy, temperature stability, and response time.

These sensors are valued for their ability to measure relative, absolute, and differential pressure in a variety of environments. They are capable of handling both gaseous and liquid mediums, making them versatile tools in many fields.

Applications of Diaphragm Pressure Sensors

Diaphragm pressure sensors find applications in an array of industries. In the oil and gas industry, they are used to monitor pressure levels in pipelines. In healthcare, they are critical for respiratory equipment and anesthesia delivery systems, where precise pressure readings are essential for patient safety. Furthermore, in automotive engineering, these sensors contribute to the monitoring of fuel pressure, tire pressure, and various other critical measurements that enhance performance and safety.

As industries evolve and technology advances, the demand for high-performance diaphragm pressure sensors is on the rise

. This trend underscores the importance of selecting reputable suppliers that can provide reliable and innovative products.Choosing the Right Supplier

diaphragm pressure sensing element supplier

When it comes to sourcing diaphragm pressure sensing elements, several factors should be considered to ensure that the selected supplier can meet the specific requirements of your application.

1. Quality and Reliability It's essential to choose suppliers known for manufacturing high-quality sensors. Reviews, certifications, and compliance with industry standards (such as ISO or CE marking) are indicators of product reliability.

2. Product Range A supplier with a diverse range of diaphragm pressure sensors can be invaluable. Each application may require sensors that operate under different conditions such as varying temperature ranges, pressure capacities, and fluid compatibility.

3. Technical Support Good suppliers should offer comprehensive technical support, including assistance in sensor selection, customization options, and troubleshooting. This is crucial for optimizing the usage of the sensors in specific applications.

4. Innovation and Development The field of pressure sensing technology is dynamic, with continuous innovation. Partnering with suppliers who invest in research and development can provide access to the latest technologies and improvements in sensor performance.

5. Cost-effectiveness While quality should never be compromised, it’s essential to consider suppliers that offer competitive pricing without sacrificing product integrity. Comparing costs among different suppliers while keeping quality in check can lead to significant financial benefits.

Conclusion

Diaphragm pressure sensing elements are vital components in many industries, ensuring safe and efficient operations through accurate pressure measurements. Selecting an appropriate supplier is crucial for access to high-quality products, dependable support, and innovative technology. By weighing factors such as reliability, product diversity, technical support, and cost, businesses can make informed decisions that support their operational objectives and enhance the overall integrity of their systems. Whether for industrial processes or medical applications, the right diaphragm pressure sensor and its supplier can significantly impact performance and safety outcomes.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025