Nov . 26, 2024 22:58 Back to list

Diaphragm Pressure Gauge for Enhanced Protection and Accurate Measurements in Various Applications

Understanding Diaphragm Protection in Pressure Gauges

Pressure gauges are critical instruments used in various industries to monitor and measure the pressure of gases and liquids in systems. One significant advancement in pressure gauge technology is the diaphragm protection mechanism. This article explores the workings of diaphragm protection in pressure gauges, its advantages, and its applications across different sectors.

What is a Diaphragm Pressure Gauge?

A diaphragm pressure gauge utilizes a flexible diaphragm, typically made of materials like stainless steel, to measure pressure. When pressure is applied to one side of the diaphragm, it deforms, allowing for accurate measurement of the pressure exerted. The movement of the diaphragm is translated into a mechanical motion that moves the pointer on the gauge scale, providing a visual indication of pressure levels.

The Role of Diaphragm Protection

The primary function of diaphragm protection in pressure gauges is to safeguard the measuring element from damaging high pressures, corrosive substances, and harsh operating conditions. This protection is essential in ensuring the accuracy and longevity of the gauge. Here are some key aspects of diaphragm protection

1. Isolation from Process Media Diaphragm protection isolates the sensing element from the process medium. This is particularly crucial when dealing with aggressive or corrosive fluids that could compromise the integrity of the measuring components.

2. Overpressure Protection Diaphragm protection mechanisms are designed to withstand high-pressure spikes, preventing damage to sensitive components. The diaphragm can flex to accommodate sudden pressure changes without breaking, which is vital in environments where pressure surges are common.

3. Prevention of Blockages In some applications, particularly those involving viscous fluids or slurries, the diaphragm design can help prevent blockage of the pressure measurement system. The flexible nature of the diaphragm allows it to displace and keep the sensing port open.

4. Temperature Control In environments where there are significant temperature variations, diaphragm protection helps maintain the accuracy of the readings. High temperatures can cause the pressure within a gauge to change, but a well-designed diaphragm can minimize this effect by providing thermal stability.

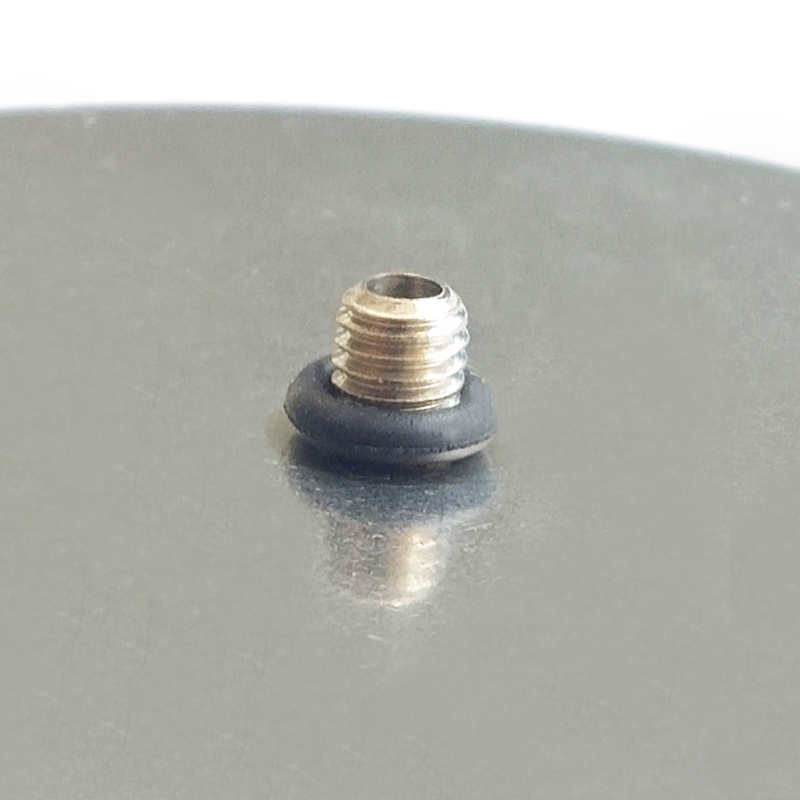

diaphragm protection pressure gauge jah

Advantages of Using Diaphragm Protected Pressure Gauges

1. Enhanced Accuracy By isolating the measuring element from the process, diaphragm protected gauges reduce the influence of temperature, humidity, and corrosive effects, thereby enhancing measurement accuracy.

2. Increased Durability These gauges have a longer lifespan due to their robust design and ability to withstand harsh conditions. This durability translates to lower maintenance costs and reduced downtime in industrial operations.

3. Versatility Diaphragm pressure gauges can be used in various applications ranging from chemical processing, oil and gas, food and beverage, to pharmaceuticals. Their ability to handle different media types makes them a versatile choice for many industries.

4. Safety By preventing leaks and protecting sensitive components from harsh conditions, diaphragm protection enhances the safety of the system. This is particularly important in industries where pressure gauges are used to monitor potentially hazardous materials.

Applications in Different Industries

Diaphragm protected pressure gauges are employed across a variety of sectors. In the chemical industry, they are used to monitor the pressure of reactive and corrosive substances, ensuring safe operations. In the oil and gas sector, these gauges help in measuring the pressure of gases and liquids under high temperatures and pressures. In the food and beverage industry, they are essential for maintaining product quality and safety by monitoring pressure in processes like pasteurization.

Conclusion

Diaphragm protection in pressure gauges represents a significant evolution in pressure measurement technology. By isolating the sensing element from challenging environments and extreme pressures, these gauges provide reliable, accurate, and safe pressure readings across multiple industries. As industries continue to evolve and face new challenges, the importance of robust measurement solutions like diaphragm protected pressure gauges will only increase, ensuring safety and efficiency in various applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025