Nov . 24, 2024 00:56 Back to list

diaphragm sealed pressure gauges

Understanding Diaphragm-Sealed Pressure Gauges

Pressure gauges are essential instruments used in various industries to measure the pressure of gases or liquids. Among the different types of pressure gauges, diaphragm-sealed pressure gauges offer significant advantages, particularly in applications involving corrosive, viscous, or high-purity fluids. This article delves into the functioning, benefits, and applications of diaphragm-sealed pressure gauges.

What is a Diaphragm-Sealed Pressure Gauge?

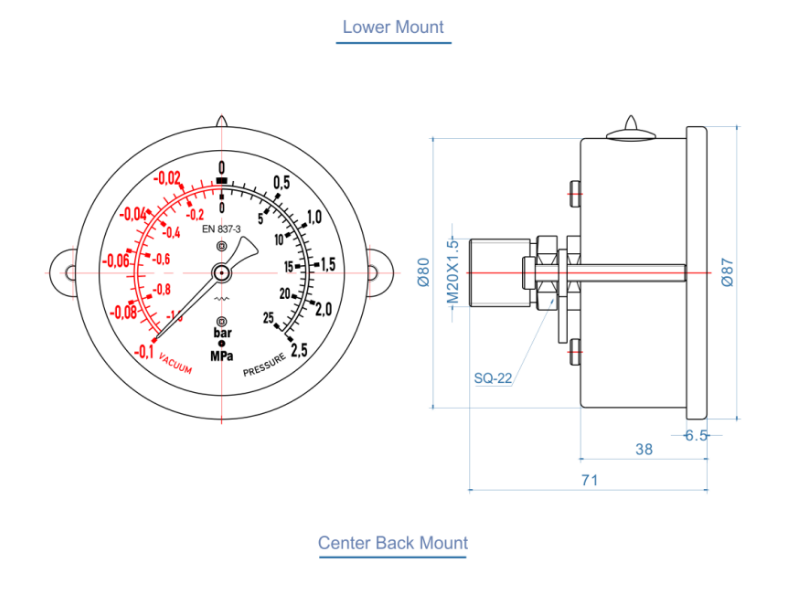

A diaphragm-sealed pressure gauge utilizes a flexible diaphragm as the primary sensing element. This diaphragm separates the pressure measuring mechanism from the media being measured. When pressure is applied to the fluid on one side of the diaphragm, it deflects, and this movement translates into a measurable output on the gauge. The diaphragm is typically made from materials such as stainless steel, PTFE, or other corrosion-resistant alloys, making it suitable for hostile environments.

Advantages of Diaphragm-Sealed Pressure Gauges

1. Protection Against Corrosion One of the most significant benefits of diaphragm-sealed gauges is their ability to protect sensitive internal components from corrosive media. This feature extends the life of the gauge, reducing maintenance costs and downtime.

2. Suitable for Viscous and Dirty Fluids Diaphragm-sealed gauges are ideal for applications involving viscous or dirty fluids that could clog or damage standard pressure gauges. The sealing mechanism prevents blockage, allowing for accurate pressure readings in challenging conditions.

3. High Accuracy and Reliability The design of diaphragm-sealed gauges allows for high levels of accuracy and reliability. As the diaphragm responds directly to pressure changes, these gauges can provide precise measurements essential in critical processes.

4. Ease of Installation These gauges can be mounted in various orientations and are relatively easy to install, making them versatile for different setups in industries such as oil and gas, pharmaceuticals, and food processing.

diaphragm sealed pressure gauges

Applications of Diaphragm-Sealed Pressure Gauges

Diaphragm-sealed pressure gauges are widely used across various sectors

- Chemical Industry In processes involving corrosive chemicals, diaphragm-sealed gauges enable accurate pressure readings while protecting the internals from chemical attack.

- Food and Beverage In the food industry, maintaining the purity and safety of products is paramount. Diaphragm-sealed gauges prevent contamination, ensuring compliance with health regulations.

- Pharmaceuticals The pharmaceutical industry demands extreme precision and cleanliness. Diaphragm-sealed gauges help meet these requirements by isolating the media and providing accurate readings.

- Oil and Gas In oil and gas applications, the ability to measure high-pressure fluids safely and accurately is critical. Diaphragm-sealed gauges withstand harsh conditions, ensuring reliability.

- Water Treatment Water quality monitoring often involves various chemicals, making diaphragm-sealed gauges suitable for maintaining accurate pressure readings while protecting from corrosive substances.

Conclusion

Diaphragm-sealed pressure gauges are invaluable tools in many industries, enhancing measurement accuracy and equipment longevity. Their ability to work effectively with challenging fluids and harsh environments makes them a preferred choice for engineers and technicians. As industries continue to evolve and demand higher standards of accuracy and safety, diaphragm-sealed pressure gauges will remain a critical component in the toolkit of pressure measurement solutions. Whether in the chemical, food, pharmaceutical, or oil and gas industries, these gauges not only ensure precise measurement but also promote a safer, more efficient working environment.

-

Precision Differential Pressure Gauge Assembly Reliable & Customizable Solutions

NewsMay.29,2025

-

WIKA Sanitary Diaphragm Pressure Gauge High Precision & Durability

NewsMay.29,2025

-

HD Fire Pressure Gauges High Accuracy & Durable Solutions

NewsMay.28,2025

-

Custom Singles Capsule Systems Top Exporters & Factories

NewsMay.28,2025

-

Piston-Style Differential Pressure Gauges Precision & Durability

NewsMay.28,2025

-

WIKA Differential Pressure Gauge 700.04 High-Accuracy Industrial Measurement

NewsMay.28,2025