Nov . 07, 2024 12:15 Back to list

Diaphragm Seal Pressure Gauge Providers and Solutions for Industrial Applications

Understanding Diaphragm Seal Pressure Gauges Choosing the Right Supplier

In various industrial applications, precise pressure measurement is of utmost importance, especially in scenarios involving corrosive or viscous fluids. Diaphragm seal pressure gauges are essential instruments that safeguard the integrity of pressure measurements in such challenging environments. These gauges utilize a flexible diaphragm to isolate the pressure measuring element from the process fluid, thereby preventing damage and ensuring accurate readings. As industries increasingly prioritize reliability and precision in their operations, selecting the right supplier for diaphragm seal pressure gauges becomes a crucial decision.

What is a Diaphragm Seal Pressure Gauge?

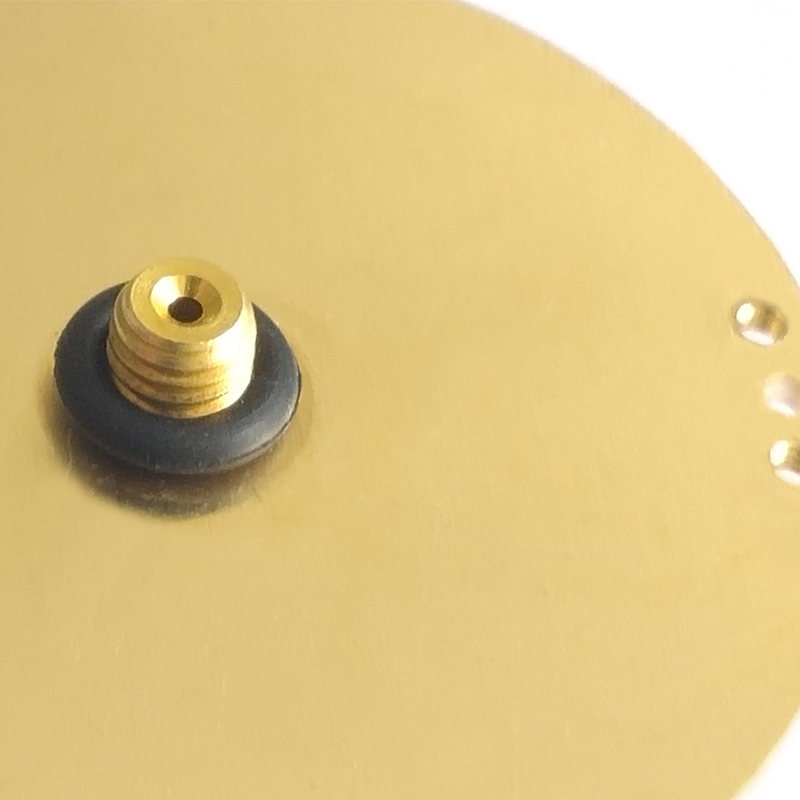

A diaphragm seal pressure gauge consists of two primary components the diaphragm seal and the pressure gauge itself. The diaphragm, typically made from materials like stainless steel, elastomers, or Teflon, flexes in response to fluid pressure. This deformation transmits the pressure to the gauge without direct contact between the fluid and the gauge mechanism. This design minimizes the risks of corrosion and clogging, and it enhances the gauge's durability—even in harsh environments.

Why Opt for Diaphragm Seal Pressure Gauges?

The primary advantage of diaphragm seal pressure gauges is their ability to handle aggressive media. Industries such as chemical processing, oil and gas, and pharmaceuticals often deal with corrosive substances that can damage traditional pressure gauges. Diaphragm seals provide a protective barrier that prevents leakage and contamination, making them ideal for these applications.

Furthermore, these gauges can accommodate viscous fluids and slurries, which can clog standard gauges. By using a diaphragm seal, the pressure measurement remains unaffected by the characteristics of the fluid, thus providing more reliable and consistent readings.

Key Factors in Selecting a Supplier

diaphragm seal pressure gauges supplier

1. Product Quality and Standards When choosing a supplier, it's essential to consider their product quality. Look for suppliers who adhere to international quality standards such as ISO 9001. High-quality materials and manufacturing processes contribute to the longevity and reliability of the gauges.

2. Customization Options Different industries have varied requirements regarding pressure ranges, materials, and operational conditions. A good supplier should offer customizable solutions to meet these specific needs. This flexibility can be crucial for ensuring the gauges perform optimally in unique applications.

3. Technical Support and Expertise A supplier with a knowledgeable team can provide critical support in selecting the right gauge for your application. Look for suppliers who offer comprehensive technical assistance, including installation guidance, maintenance services, and troubleshooting advice.

4. Reputation and Reviews Research the supplier's reputation in the industry. Customer reviews, case studies, and testimonials can offer valuable insights into the supplier's reliability and customer service. A supplier with a proven track record will likely provide a better experience.

5. Lead Time and Availability Timely delivery is crucial in any industry. Ensure that the supplier can meet your timeframes without compromising on quality. Their ability to maintain sufficient stock levels can also impact lead times for custom orders.

6. Pricing and Value for Money While price shouldn’t be the sole deciding factor, it’s essential to consider the cost versus the value provided. Sometimes, low-cost products may come with reliability issues that could result in higher long-term costs due to replacements or downtime.

Conclusion

Diaphragm seal pressure gauges are vital for ensuring accurate measurements in challenging industrial environments. Selecting a reputable supplier is fundamental to maximizing the benefits of these instruments. By considering factors such as product quality, customization options, technical expertise, and customer reputation, businesses can make informed decisions that enhance their operational reliability and efficiency. In an age where precision and reliability are paramount, investing in quality diaphragm seal pressure gauges from the right supplier is indispensable for success in various industries.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025