Aug . 29, 2024 17:13 Back to list

Differential Pressure Gauge for Chilled Water Systems

Understanding Differential Pressure Gauges in Chilled Water Systems

In the realm of HVAC (Heating, Ventilation, and Air Conditioning) systems, the efficient management of chilled water is crucial for ensuring optimal performance and energy efficiency. One of the key instruments used to maintain and monitor the performance of chilled water systems is the differential pressure gauge. This article explores the significance of differential pressure gauges, their working principles, and their applications in chilled water systems.

What is a Differential Pressure Gauge?

A differential pressure gauge is a device used to measure the difference in pressure between two points within a system. Unlike a standard pressure gauge that measures pressure relative to the atmosphere, a differential pressure gauge provides insights into variations that could indicate issues such as blockages or imbalances in the flow of fluids—in this case, chilled water.

Working Principle

The device operates by using a diaphragm or a piston that reacts to pressure differences between two inputs. One side of the gauge senses the pressure of the inlet water while the other side measures the pressure at a downstream point. The gauge then displays the difference in pressure, which serves as an indicator of the system’s performance.

Importance in Chilled Water Systems

Chilled water is primarily used in air conditioning systems to absorb heat from indoor spaces. Maintaining an optimal flow of chilled water is essential to prevent issues like insufficient cooling or increased energy consumption. Here, differential pressure gauges play a vital role by allowing HVAC engineers to monitor and control water flow in piping systems.

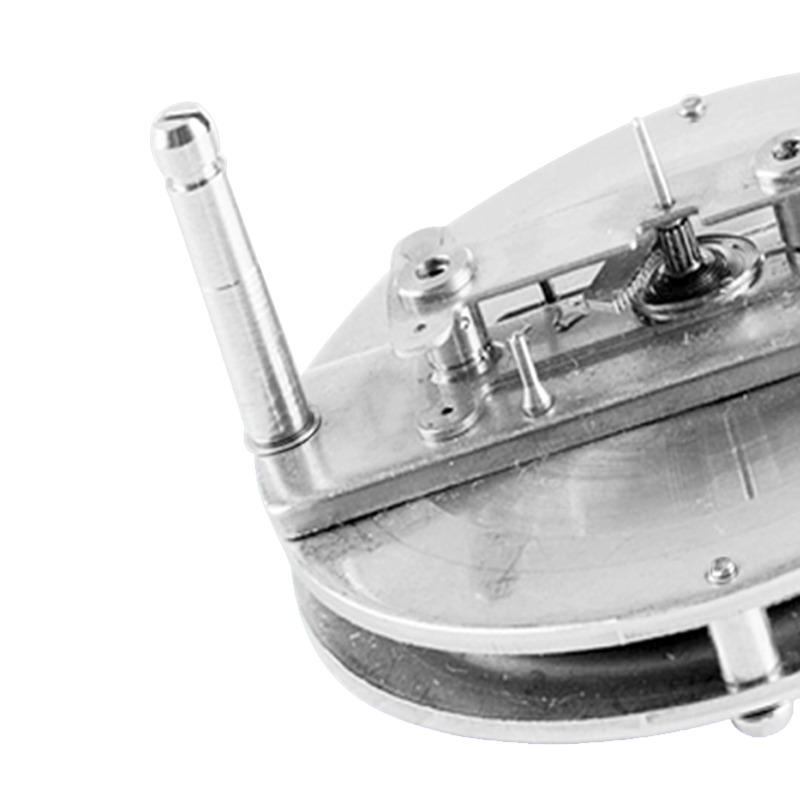

differential pressure gauge chilled water

1. Flow Monitoring By measuring the pressure drop across components like filters, coils, or pumps, engineers can determine whether there is a blockage or if a component requires maintenance. A significant drop in pressure may indicate a clogged filter, prompting immediate action.

2. System Balancing In large systems with multiple loops and branches, balanced flow is critical for efficient operation. Differential pressure gauges help ensure that chilled water is distributed evenly across different zones, preventing some areas from receiving excess cooling while others remain warm.

3. Energy Efficiency An effective chilled water system can significantly impact energy consumption. Monitoring differential pressure allows for adjustments to be made to the pumps' operation, ensuring they are running at optimal conditions. This not only conserves energy but also extends the lifespan of the pumps.

4. Preventive Maintenance Regularly monitoring differential pressure readings can serve as an early warning system for potential failures. By identifying trends in pressure readings, maintenance can be scheduled at appropriate intervals, ensuring continuous operation without unplanned downtime.

Conclusion

Differential pressure gauges are integral to the effective management of chilled water systems. By facilitating flow monitoring, system balancing, energy efficiency, and preventive maintenance, these instruments help HVAC professionals optimize system performance and energy usage. As the demand for efficient and sustainable cooling solutions continues to rise, the importance of accurately gauging pressure differences in chilled water systems will only increase. Proper utilization of differential pressure gauges can lead to enhanced operational efficiency and significant cost savings, making them a staple in modern HVAC systems.

In summary, understanding and utilizing differential pressure gauges is essential for anyone involved in maintaining chilled water systems, ensuring that buildings remain comfortable while promoting energy conservation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025