Sep . 05, 2024 21:38 Back to list

Differential Pressure Gauge with 5 Valve Manifold | Accurate Measurement Solutions

Understanding Differential Pressure Gauges with 5-Valve Manifolds

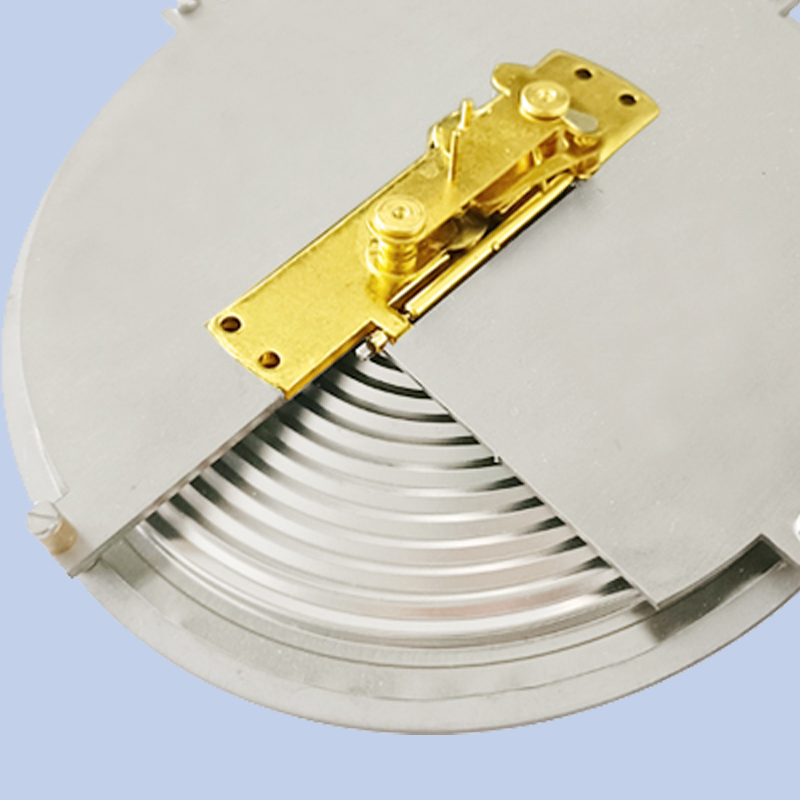

Differential pressure gauges are critical instruments used to measure the pressure difference between two points in a system. They are widely utilized in various industries, including oil and gas, chemical processing, and water treatment. A key configuration for these gauges involves a 5-valve manifold, which plays a crucial role in ensuring accurate readings and maintaining system integrity.

A typical differential pressure gauge operates by comparing the pressures at two ports. The gauge converts this differential pressure into a readable output, often displayed on a dial or digital screen. However, to ensure the accuracy of these readings, especially in harsh environments or complex systems, a properly configured manifold is essential.

The 5-valve manifold serves multiple purposes. Firstly, it facilitates the isolation of the pressure gauge from the process lines. This is essential for maintenance and calibration, as technicians can safely isolate the gauge without draining the entire system. The five valves typically include two shut-off valves, a vent valve, and two equalizing valves, each designed to control the flow of fluid through the system.

differential pressure gauge with 5 valve manifold factory

In use, when maintenance or calibration is necessary, the shut-off valves can be closed, isolating the pressure gauge from the process fluid. The vent valve allows any trapped fluid to escape safely, eliminating pressure and preventing accidental release during servicing. The equalizing valves come into play when needing to balance the pressure between the two sides of the gauge. This functionality ensures that the gauge can return to a known state before being taken back into service, thus maintaining the accuracy and reliability of the readings.

The construction of a 5-valve manifold is typically robust, often made from materials resistant to corrosion and able to withstand high pressures. This durability is vital, as these gauges and their manifolds are often installed in challenging environments where exposure to aggressive substances or extreme conditions is common.

In summary, differential pressure gauges paired with 5-valve manifolds are indispensable tools in modern industrial applications. Their design not only enhances the accuracy of pressure readings but also ensures safe and efficient maintenance of pressure measurement instruments. Understanding their operation and configuration is key for operators and engineers, facilitating better management of processes and contributing to overall operational excellence. With ongoing advancements in technology, the functionality and reliability of these gauges and their manifolds are expected to continue evolving, further solidifying their place in industrial applications.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025