Oct . 30, 2024 18:47 Back to list

differential pressure gauge 1 2 npt product

Understanding Differential Pressure Gauges A Focus on NPT Products

Differential pressure gauges are essential instruments in various industries, providing critical information about the pressure differences between two points in a system. These gauges are vital for monitoring processes in HVAC systems, filtration units, and numerous other applications where pressure differentials must be carefully managed. Among the various types available, the NPT (National Pipe Thread) differential pressure gauge stands out due to its reliability and ease of installation.

NPT differential pressure gauges are designed to measure the pressure drop caused by a fluid flowing through a filter, valve, or any similar device. The measurement is achieved by comparing the pressure at two points—upstream and downstream—allowing operators to determine the efficiency of the system. When the pressure differential exceeds a predetermined limit, it signals that maintenance or replacement may be necessary, thus preventing potential failures and ensuring optimal performance.

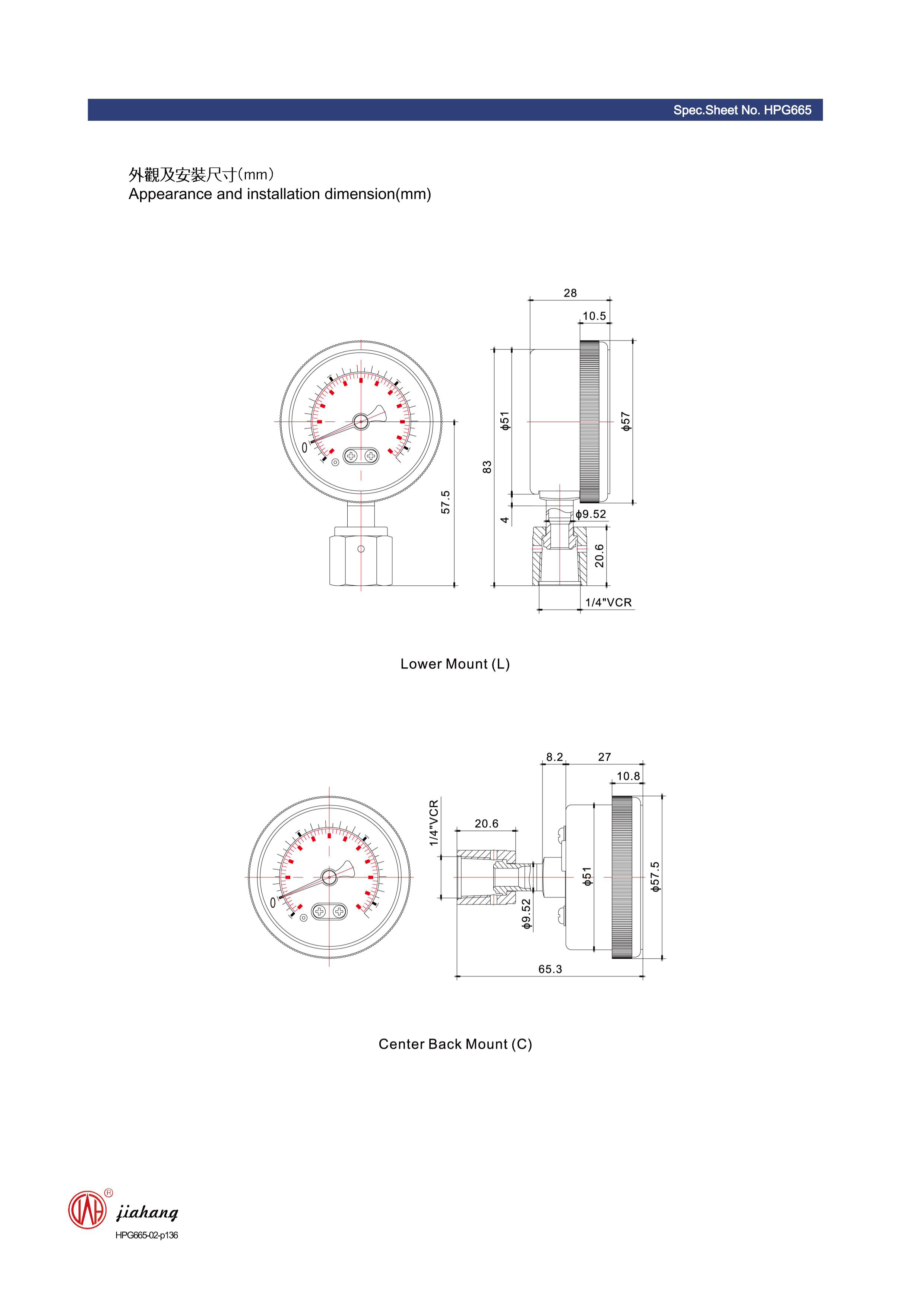

One of the primary advantages of using NPT differential pressure gauges is their compatibility with various piping systems. The NPT threading system ensures a secure and leak-free connection, critical for maintaining accurate readings and system integrity. These gauges come in various sizes and with different scale ranges, allowing for flexibility in application across different industries, including water treatment, oil and gas, and pharmaceuticals.

differential pressure gauge 1 2 npt product

Installation of NPT differential pressure gauges is straightforward, making them user-friendly for technicians and engineers. They can be installed in both vertical and horizontal positions, providing versatility in configuration. Furthermore, many models offer options for digital readouts, improving the ease of monitoring and reducing the chances of reading errors associated with analog gauges.

In terms of maintenance, NPT differential pressure gauges typically require minimal upkeep. Regular calibration checks can help to ensure accuracy over time. This aspect is crucial, especially in industries where precision is paramount, such as in the pharmaceutical or food processing sectors.

In conclusion, differential pressure gauges that utilize NPT connections are integral to modern industrial processes. They ensure that systems operate efficiently and reliably by providing accurate pressure readings and alerts when maintenance is required. Their compatibility, ease of installation, and low maintenance needs make them a preferred choice across various applications, highlighting their importance in the field of industrial instrumentation.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025