Oct . 21, 2024 01:47 Back to list

Bellow Type Differential Pressure Gauge Pricing and Specifications Overview

Understanding Bellow Type Differential Pressure Gauges A Comprehensive Guide

In various industrial applications, monitoring and measuring pressure differences is crucial for ensuring optimal operations and safety. Differential pressure gauges, particularly the bellow type, are essential instruments for this purpose. These devices are engineered to detect pressure variations, typically between two points in a system, assisting in monitoring processes like filtration, fluid flow, and level measurement.

What is a Bellow Type Differential Pressure Gauge?

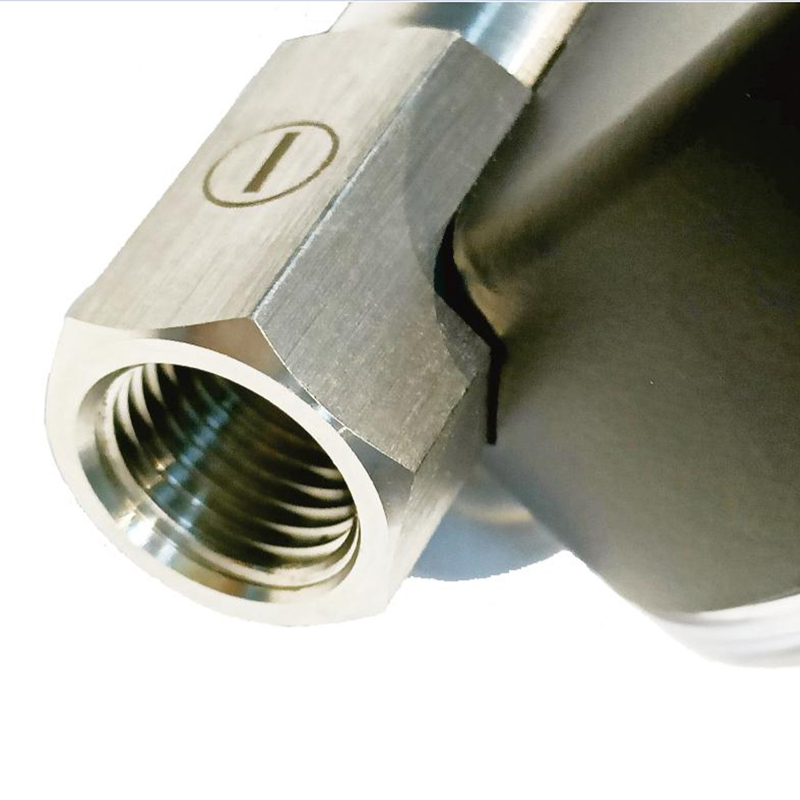

A bellow type differential pressure gauge utilizes a flexible, corrugated bellow element to measure pressure differences. When the pressure from two sources is applied, the difference causes the bellow to expand or contract. This movement is then translated into a measurement that can be read on a calibrated scale, allowing operators to understand the differential pressure between two points.

Advantages of Bellow Type Differential Pressure Gauges

1. High Accuracy One of the most compelling advantages of bellow type gauges is their accuracy. The design minimizes hysteresis and ensures quick response times to pressure fluctuations.

2. Robust Design These gauges are typically constructed from durable materials, making them suitable for a range of environments, including those with high temperatures and pressures.

3. Versatility Bellow type differential pressure gauges can measure various media, such as gases, liquids, and slurries, depending on their construction materials and design.

5. Compact Size Many bellow-type gauges are compact in design, making them ideal for installations where space is a constraint.

Key Applications

Bellow type differential pressure gauges find applications across various industries, including

differential pressure gauge bellow type pricelist

- HVAC Systems Monitoring airflow and pressure differences in HVAC systems ensures operational efficiency and helps maintain air quality. - Water Treatment These gauges are used to monitor filter conditions and water levels, contributing to effective waste management processes. - Oil and Gas They are instrumental in measuring pressure differences in pipelines and maintaining safety protocols in hazardous environments. - Pharmaceuticals Bellow gauges are essential in cleanroom environments where it’s crucial to monitor pressure differentials to prevent contamination.

Price Considerations

When looking to purchase a bellow type differential pressure gauge, several factors will influence the price

1. Material The materials used in manufacturing the gauge can significantly affect the cost. For instance, gauges made from stainless steel will typically be more expensive than those made from standard alloys.

2. Size and Range The size of the gauge and its differential pressure range can also influence the price. Larger gauges with higher pressure ratings tend to cost more.

3. Accuracy and Calibration Gauges designed for high accuracy with specific calibration standards may come at a premium.

4. Brand and Certification Leading brands and those with certification for specific industries (like FDA, ISO) may carry higher costs due to their reputation and assured reliability.

5. Additional Features Some bellow type gauges come with added features like digital displays, remote reading capabilities, and alarm functionalities, affecting the price distinctly.

Conclusion

Bellow type differential pressure gauges are indispensable tools for a variety of applications requiring precise pressure monitoring and control. Their high accuracy, durability, and low maintenance needs make them a favored choice across numerous industries. When considering a purchase, it's important to evaluate the specific requirements of your application, as well as the factors affecting the pricing to ensure the best investment for your needs.

In today’s competitive market, obtaining a comprehensively detailed price list from various suppliers, along with understanding the underlying factors that contribute to the cost, will empower users to make informed purchasing decisions. As industries continue to evolve and embrace advanced measuring technologies, bellow type differential pressure gauges will remain integral to maintaining operational excellence.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025