Nov . 19, 2024 01:15 Back to list

Exploring the Applications of Bourdon Tube Differential Pressure Gauges in Industrial Settings

Understanding Differential Pressure Gauges The Role of Bourdon Tubes

Differential pressure gauges are essential instruments used in various industries to measure the difference in pressure between two points in a system. One of the most common designs for these gauges is the Bourdon tube, a mechanical device that translates pressure differences into a readable measurement. This article explores the functionality, advantages, and applications of differential pressure gauges utilizing Bourdon tube technology.

The Bourdon Tube Mechanism

The Bourdon tube was invented by the French engineer Eugène Bourdon in the mid-19th century and has since become a standard design in pressure measurement. The basic structure of a Bourdon tube consists of a curved, hollow metal tube, sealed at one end and connected to a pressure source at the other. When pressure is applied, the tube attempts to straighten due to the internal pressure, and this movement is translated into a needle reading on a calibrated dial.

In differential pressure applications, two Bourdon tubes may be used to measure the pressure on either side of a diaphragm, or a single Bourdon tube may be calibrated to represent the differential pressure between two input lines. This flexibility allows for accurate monitoring of pressure variations, which can be critical in many processes.

Advantages of Bourdon Tube Differential Pressure Gauges

1. Durability Bourdon tubes are made from robust materials such as brass, stainless steel, or Monel, which ensure longevity and reliability even in harsh environments.

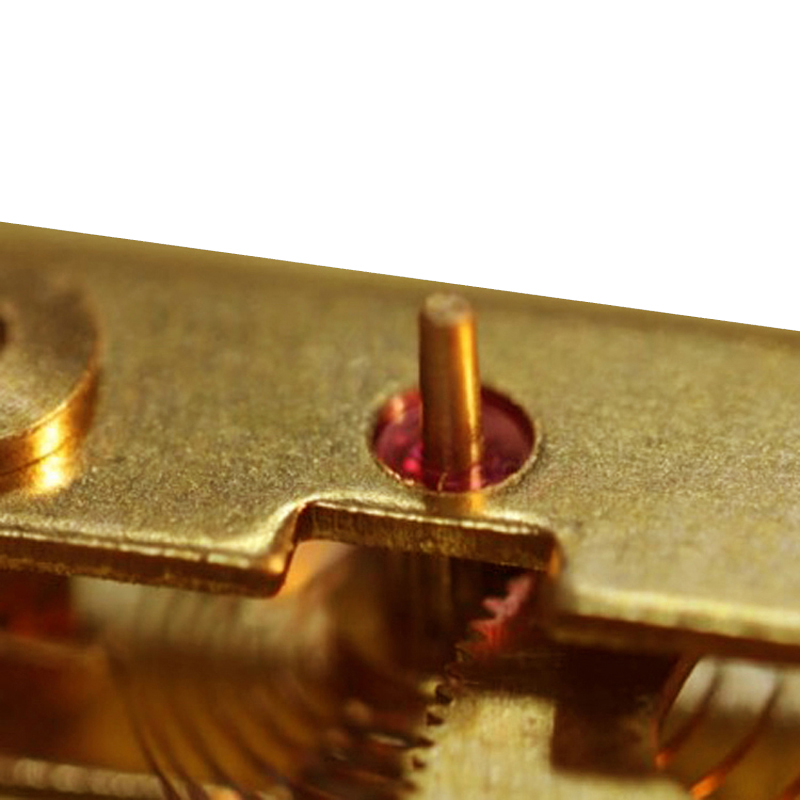

differential pressure gauge bourdon tube product

3. Wide Range of Measurements Differential pressure gauges utilizing Bourdon tubes can measure pressure differences ranging from very low to very high, making them suitable for various applications.

4. Cost-Effectiveness Compared to electronic pressure gauges, Bourdon tube gauges are often more affordable, making them an economical choice for many industries.

5. No Need for External Power Because they are mechanical, Bourdon tube gauges do not require external power sources, reducing operational complexity and increasing reliability.

Applications in Industry

Differential pressure gauges are crucial in a multitude of applications across various industries. In the oil and gas sector, they are used to monitor pressure drops in pipelines, ensuring safe and efficient operation. In HVAC systems, these gauges help maintain optimal airflow by measuring the pressure difference across filters and ducts.

Additionally, in water treatment facilities, Bourdon tube differential pressure gauges are used to monitor the pressure across membranes and other filtration systems. In pharmaceutical manufacturing, these gauges ensure that processes operate within specified pressure ranges, contributing to product quality and safety.

Conclusion

Differential pressure gauges with Bourdon tubes play an integral role in monitoring and controlling processes across numerous industries. Their durable construction, simplicity of design, and affordability make them a favored choice for many applications. As industries continue to evolve and the demand for accurate pressure measurement grows, innovations in Bourdon tube technology will likely enhance the functionality and precision of these essential instruments. Understanding how these devices work and their advantages can aid in the selection and application of the appropriate pressure monitoring solutions for specific needs.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025