Oct . 17, 2024 04:29 Back to list

Inline Differential Pressure Gauge Exporter for Enhanced Monitoring Solutions

Differential Pressure Gauge in Line Exporter Understanding Its Importance and Applications

In various industrial processes, the measurement of pressure differences is critical for ensuring operational efficiency and safety. One of the foremost instruments used for this purpose is the differential pressure gauge. This device plays an essential role in measuring the difference in pressure between two points in a system, which can be crucial for monitoring flow rates, fluid levels, and overall system health.

What is a Differential Pressure Gauge?

A differential pressure gauge is a type of pressure measuring instrument that displays the difference in pressure between two points. This calculated difference can indicate many operational parameters, such as flow rates in pipes, level measurements in tanks, and filter conditions in various industrial applications. Given their functional versatility, these gauges are employed across multiple sectors, including oil and gas, water treatment, pharmaceuticals, and manufacturing.

How Does It Work?

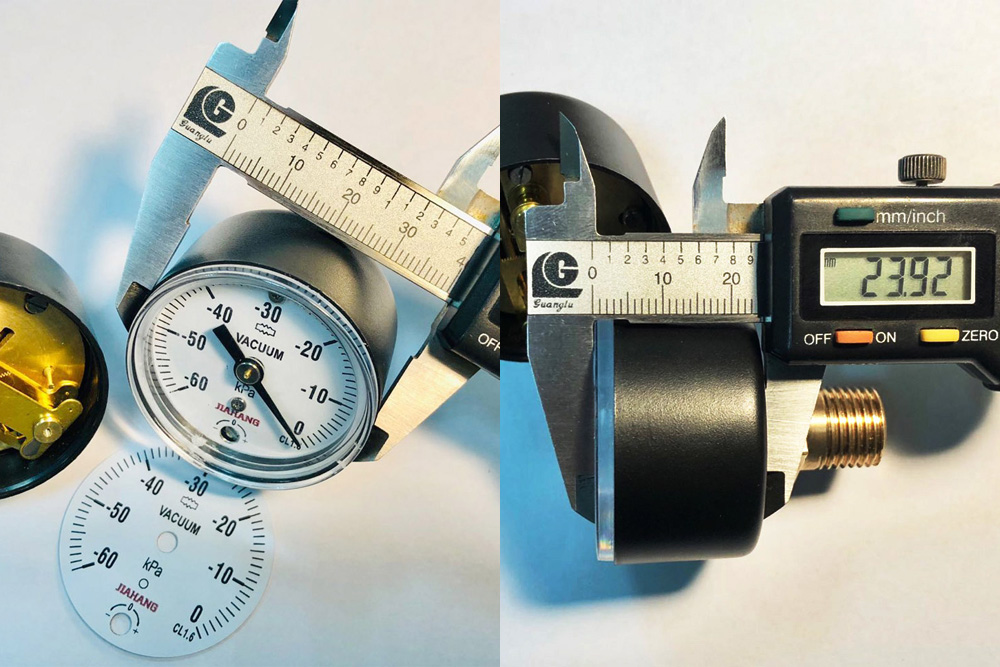

The working principle of a differential pressure gauge is relatively straightforward. It consists of two pressure ports connected to the system where the pressure measurements are to be taken. The gauge typically contains a sensing element, such as a diaphragm, which flexes in response to pressure changes. This movement is converted into a rotational or linear displacement that the gauge then translates into a readable measurement on its dial or digital display.

Applications of Differential Pressure Gauges

Differential pressure gauges find widespread applications in various industries

differential pressure gauge in line exporter

1. Fluid Flow Measurement In piping systems where two different pressure points are critical, differential pressure gauges help determine flow rates. This information is vital for managing and optimizing processes in industries like chemical manufacturing and water treatment.

2. Filter Monitoring In filtration systems, monitoring the pressure difference across a filter can indicate when it’s time to replace or clean the filter. A significant difference in pressure may suggest that the filter is clogged and can adversely affect system performance.

3. Level Measurement Differential pressure gauges can also be used in level measurement applications, especially in closed tanks. By measuring the difference in pressure between the bottom and the top of a liquid column, the gauge can provide an accurate level reading, which is particularly useful in petroleum and chemical storage tanks.

4. Safety Monitoring These gauges play a significant role in enhancing safety in industrial environments. They help monitor conditions that could lead to equipment failures or hazardous situations, such as sudden pressure drops or spikes, allowing for timely intervention.

Choosing the Right Differential Pressure Gauge

When selecting a differential pressure gauge, several factors must be considered, including the intended application, the range of pressure differences to be measured, the type of fluid involved (gas or liquid), and environmental conditions (temperature, humidity, etc.). Additionally, the gauge's material construction must be compatible with the media it will measure to prevent corrosion or damage.

Conclusion

The differential pressure gauge is a critical instrument in modern industrial applications, providing invaluable data that support efficient operations and safety protocols. As industries continue to evolve, the importance of accurate pressure measurement will only increase, making it essential for facilities to invest in reliable and high-quality differential pressure gauges. Understanding their functionality, applications, and selection criteria can significantly enhance process control and ensure smoother operations across various sectors. Investing in these gauges not only optimizes operational efficiencies but also helps mitigate risks associated with pressure-related anomalies.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025