Jan . 20, 2025 13:32 Back to list

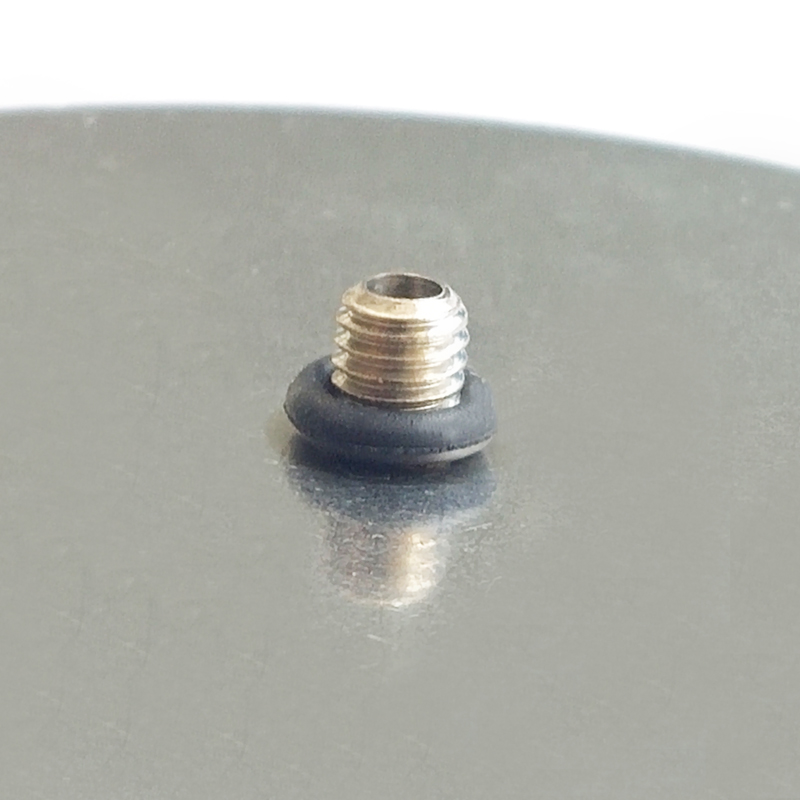

Differential Pressure Gauge-Magnetic piston francois typeYCC-80.03(851.3)

Differential pressure gauges play a vital role in monitoring and controlling fluid dynamics across numerous industrial applications. Selecting the right distributor for these intricate instruments is crucial to ensuring accuracy, longevity, and compatibility with your systems. In a saturated market, distinguishing between distributors demands an understanding of their expertise, experience, authoritativeness, and trustworthiness.

Trustworthiness is the bedrock of long-term distributor relationships. A trustworthy distributor stands by the quality of their products and services by offering comprehensive warranties and after-sales support. They maintain transparency in pricing and procurement, ensuring no hidden costs. Reliability in delivering orders on time, providing consistent product quality, and supporting with technical advice establishes a reliable business relationship that businesses can depend upon. Product knowledge is another crucial lens through which distributors can be evaluated. An ideal distributor should not only supply differential pressure gauges but also provide insights on their operation, potential challenges, and applications. They should maintain a diverse inventory, carrying everything from traditional mechanical gauges to state-of-the-art smart gauges. This versatility indicates a commitment to catering to varied industrial demands and staying ahead of technological trends. Customer testimonials and reviews can shed light on a distributor's real-world performance. Unbiased feedback from other businesses can provide insights into the distributor's customer service, product reliability, and problem-solving efficiency. Engaging with a distributor who has a track record of positive feedback ensures they value client relationships and are responsive to the evolving needs of the industry. In conclusion, selecting the right differential pressure gauges distributor involves more than just pricing comparisons. It requires a comprehensive evaluation of their experience, expertise, authoritativeness, and trustworthiness. A reliable distributor will not only supply quality instruments but will also act as a partner in ensuring your processes remain efficient, safe, and compliant with industry standards. By prioritizing these qualities, businesses can foster partnerships that support their operational goals and adapt to the changing landscape of industrial needs.

Trustworthiness is the bedrock of long-term distributor relationships. A trustworthy distributor stands by the quality of their products and services by offering comprehensive warranties and after-sales support. They maintain transparency in pricing and procurement, ensuring no hidden costs. Reliability in delivering orders on time, providing consistent product quality, and supporting with technical advice establishes a reliable business relationship that businesses can depend upon. Product knowledge is another crucial lens through which distributors can be evaluated. An ideal distributor should not only supply differential pressure gauges but also provide insights on their operation, potential challenges, and applications. They should maintain a diverse inventory, carrying everything from traditional mechanical gauges to state-of-the-art smart gauges. This versatility indicates a commitment to catering to varied industrial demands and staying ahead of technological trends. Customer testimonials and reviews can shed light on a distributor's real-world performance. Unbiased feedback from other businesses can provide insights into the distributor's customer service, product reliability, and problem-solving efficiency. Engaging with a distributor who has a track record of positive feedback ensures they value client relationships and are responsive to the evolving needs of the industry. In conclusion, selecting the right differential pressure gauges distributor involves more than just pricing comparisons. It requires a comprehensive evaluation of their experience, expertise, authoritativeness, and trustworthiness. A reliable distributor will not only supply quality instruments but will also act as a partner in ensuring your processes remain efficient, safe, and compliant with industry standards. By prioritizing these qualities, businesses can foster partnerships that support their operational goals and adapt to the changing landscape of industrial needs.

Share

Latest news

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025