Nov . 10, 2024 01:26 Back to list

Supplier Quotes for Differential Pressure Gauges and Measurement Solutions

Understanding Differential Pressure Gauges A Comprehensive Guide for Distributors

In various industrial and laboratory applications, measuring pressure differences is crucial for ensuring the proper functioning of equipment and safety of operations. Differential pressure gauges are indispensable tools for monitoring and controlling processes that require accuracy and reliability. As distributors of differential pressure gauges, understanding their mechanics, applications, and market trends is essential to provide your clients with the best solutions.

What are Differential Pressure Gauges?

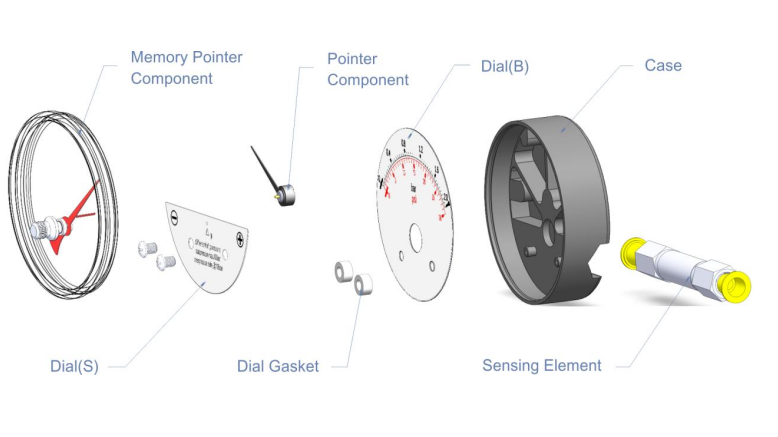

Differential pressure gauges measure the difference in pressure between two points. This measurement is vital in numerous applications, including HVAC systems, filtration, lubrication, and process control. These gauges typically consist of two pressure sensing ports one connected to the high-pressure side and the other to the low-pressure side. The device then displays the pressure difference, often in units of psi, bar, or kPa.

How Do Differential Pressure Gauges Work?

Differential pressure gauges function on the principles of fluid mechanics. They can be mechanical or electronic types. Mechanical gauges operate through a diaphragm or a Bourdon tube that bends under pressure, translating the pressure change into a readable scale. Electronic gauges, in contrast, often use sensors to convert pressure differences into electrical signals, which are then processed and displayed digitally.

Applications in Various Industries

1. HVAC Systems In heating, ventilation, and air conditioning systems, differential pressure gauges play a crucial role in monitoring airflow and filter conditions. By measuring the pressure drop across filters, technicians can determine when maintenance is required, ensuring system efficiency.

2. Process Industries Industries such as chemical manufacturing and oil and gas utilize differential pressure gauges to monitor fluid flow and levels in tanks and pipelines. This ensures that processes remain within safe and efficient operating parameters.

differential pressure gauges distributor quotes

4. Pharmaceuticals In the pharmaceutical industry, maintaining precise environmental conditions is critical. Differential pressure gauges are essential for monitoring cleanliness in sterile environments, helping to assure compliance with regulatory standards.

Choosing the Right Differential Pressure Gauge

As a distributor, selection and recommendation of the right differential pressure gauge depend on several factors

- Measurement Range Understanding the specific application helps in choosing a gauge that can operate effectively within the required pressure range. - Accuracy Different gauges offer varying levels of precision. For critical applications, selecting high-accuracy models is essential.

- Environmental Conditions Consider the environmental factors where the gauge will be used, including temperature, humidity, and potential exposure to corrosive substances. Choose materials and designs that withstand these conditions.

- Output Type Depending on customer needs, you may offer mechanical gauges for straightforward applications or digital gauges for more complex systems that require additional data tracking and display.

Market Trends

The demand for differential pressure gauges is growing, driven by advancements in technology and the increasing sophistication of industrial processes. Manufacturers are focusing on producing smart gauges that integrate with IoT devices, enabling real-time monitoring and data analysis. As a distributor, staying updated on these trends can provide opportunities to enhance product offerings and customer service.

Conclusion

Differential pressure gauges are vital components across various industries, ensuring safety, efficiency, and performance. As a distributor, understanding the technical aspects, applications, and market landscape of these gauges will enable you to better serve your clients. By providing reliable products and informed consultation, you can position your business as a trusted partner in their operational success. Regularly engaging with manufacturers and keeping abreast of technological advancements will allow you to maintain a competitive edge in this vital sector.

-

High-Precision 5 Valve Manifold Differential Pressure Gauge Suppliers

NewsApr.29,2025

-

High-Precision Diaphragm Vacuum Pressure Gauges Manufacturers & Quotes

NewsApr.29,2025

-

Omega Differential Pressure Gauges High Accuracy & Durability

NewsApr.28,2025

-

Low Pressure Differential Pressure Gauges Precision Solutions & Quotes

NewsApr.28,2025

-

Digital Diaphragm Pressure Gaauge Precision Measurement & OEM Quotes

NewsApr.28,2025

-

Differential Pressure Gauge China Price High-Accuracy & Best Quotes

NewsApr.28,2025