Dec . 04, 2024 10:23 Back to list

Factory Production of Differential Pressure Gauges for Precise Measurement Solutions

Understanding Differential Pressure Gauges A Deep Dive into Their Function and Importance

Differential pressure gauges are essential instruments widely used in various industries to measure the difference in pressure between two points in a system. These devices play a crucial role in process monitoring, control, and optimization across numerous applications, including oil and gas, pharmaceuticals, water treatment, and HVAC systems. This article aims to explore the functionality, types, applications, and advantages of differential pressure gauges, highlighting their importance in industrial operations.

What is a Differential Pressure Gauge?

A differential pressure gauge is designed to measure the pressure difference between two locations. The basic principle involves sensing how much greater the pressure is at one point compared to another. This measurement is vital for understanding flow rates, filter conditions, liquid levels, and the overall health of a system.

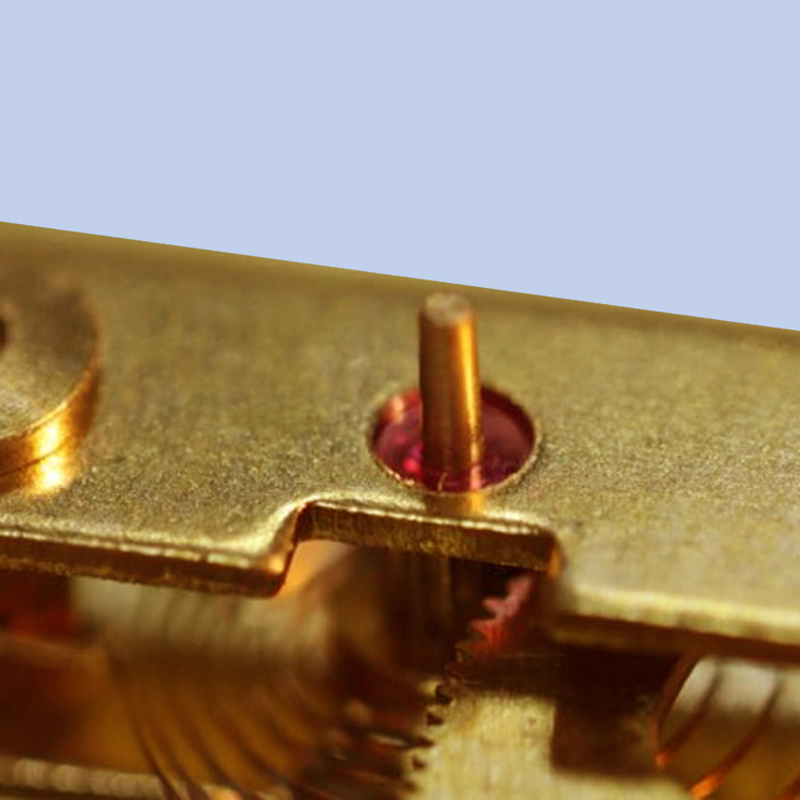

The structure of a differential pressure gauge typically consists of two input ports and a sensing element, which can be a diaphragm, bourdon tube, or a piezoelectric element. The output is displayed in various units such as psi, bar, or Pascal.

Types of Differential Pressure Gauges

There are several types of differential pressure gauges, which can be classified based on their design and operating principles

1. Mechanical Differential Pressure Gauges These utilize mechanical components, such as diaphragms or membranes, to measure pressure differences. They are robust, reliable, and do not require external power, making them suitable for many industrial applications.

2. Digital Differential Pressure Gauges With advancements in technology, digital gauges have become popular. These devices often provide higher accuracy and can offer additional features such as data logging and connectivity options for integration into broader monitoring systems.

3. Capacitive Differential Pressure Gauges These gauges operate based on the variation in capacitance due to pressure changes. They offer high sensitivity and are used in applications requiring precise measurements.

4. Piezoelectric Differential Pressure Gauges Utilizing the piezoelectric effect, these devices can detect changes in pressure through electronic signals. They are used in scenarios where fast response times are critical.

Applications of Differential Pressure Gauges

differential pressure gauges factory

Differential pressure gauges find application in a wide array of fields. Some common uses include

- Flow Measurement In processes where fluid flows through pipes, the differential pressure across a flow meter can indicate the flow rate accurately.

- Filtration Monitoring By measuring the pressure drop across filters, facilities can determine when filters need cleaning or replacement, ensuring optimal filtration efficiency.

- Level Measurement In tanks and vessels, differential pressure gauges can be used to measure liquid levels, as the pressure difference correlates with the height of the liquid column.

- HVAC Systems These gauges can monitor airflow across ducts and help maintain optimal system performance by ensuring that air pressure remains within desired limits.

Importance of Differential Pressure Gauges in Industry

The significance of differential pressure gauges cannot be overstated. They are vital for

- Ensuring Safety By monitoring pressure levels, these gauges help prevent equipment failures, leaks, and potential safety hazards in industrial operations.

- Enhancing Efficiency They enable precise control of processes, which can lead to improved efficiency and reduced operational costs.

- Facilitating Compliance Many industries are subject to strict regulations regarding pressure levels. Differential pressure gauges help ensure conformity to these standards by providing accurate measurements.

Conclusion

In summary, differential pressure gauges are indispensable tools in many industrial sectors. Their ability to measure pressure differences accurately makes them vital for monitoring and controlling various processes. As technology continues to evolve, these instruments will likely become even more sophisticated, paving the way for greater efficiency and safety in industrial operations. Understanding and utilizing differential pressure gauges effectively is essential for professionals aiming to optimize their processes and maintain high standards of safety and quality.

-

Bourdon-Type Differential Pressure Gauges High Accuracy & Affordable Pricing

NewsMay.22,2025

-

Vacuum Differential Pressure Gauges High-Precision Solutions & Quotes

NewsMay.22,2025

-

Durable Diaphragm Pressure Elements High Accuracy & Custom Quotes

NewsMay.22,2025

-

AG Precision Pressure Gauges High Accuracy & Global Exporters

NewsMay.21,2025

-

Ashcroft Diaphragm Pressure Gauges Precision & Durability

NewsMay.21,2025

-

Micro Differential Pressure Gauges High-Precision & Compact Solutions

NewsMay.20,2025